Pretreatment method for ultra-high pressure blasting wood fiber material

A lignocellulosic material and ultra-high pressure technology, which is applied in fiber raw material processing, fiber raw material, raw material separation, etc., can solve the problems of long production cycle, high equipment requirements, and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

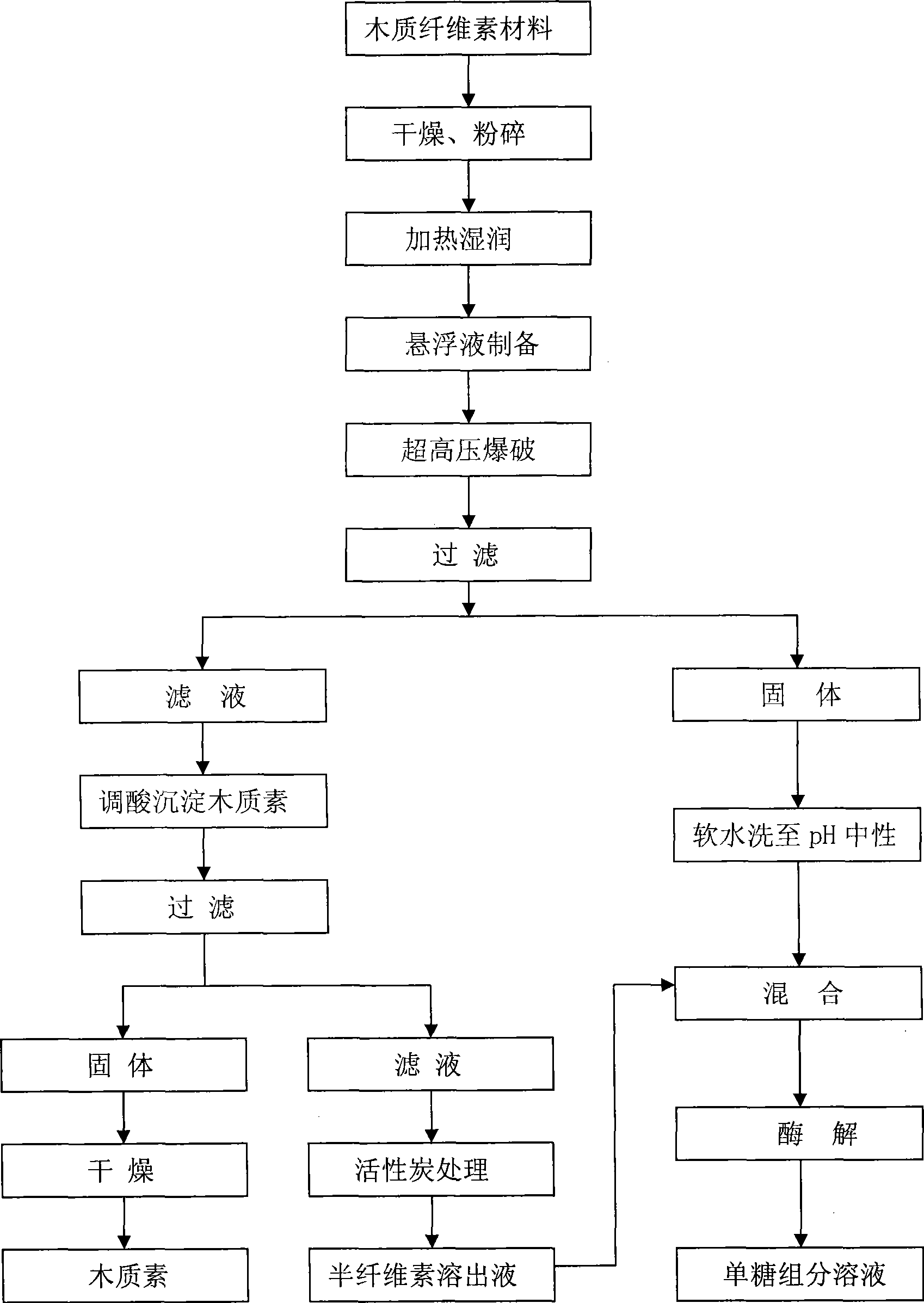

Method used

Image

Examples

Embodiment 1

[0050] 1. Drying and crushing of materials: The bagasse is taken back from the sugar factory and air-dried naturally or dried at 70°C until the moisture content is about 7%, crushed with a suspension type crusher (WKF type), and passed through a 40-mesh sieve.

[0051] 2. Heating and wetting of materials: prepare 0.2% sodium hydroxide solution, add bagasse to make a 5% suspension solution, stir evenly, and heat at 100°C for 10 minutes to make bagasse wet and settle.

[0052] 3. Preparation of material suspension: add xanthan gum to the bagasse suspension to a concentration of 0.2%, stir and dissolve evenly, so that the bagasse is in a suspended state.

[0053]4. Ultra-high pressure blasting: use a high-pressure homogenizer (GYB40-10S type, maximum working pressure 100MPa) produced by Shanghai Donghua High-pressure Homogenizer Factory, and install an agitator in the homogenizer feed hopper. When processing, pour the material into the hopper, start the agitator immediately, and ...

Embodiment 2

[0062] 1. Material drying and crushing: cane pith is the central pith of sugarcane straw. In sugar mills, it usually refers to the smaller parts left after bagasse is sold to paper mills. This part of the material is not suitable for papermaking due to its short fibers. The cane pith bought back from the sugar factory is naturally air-dried or dried at 70°C with the example 1, until the moisture content is about 7%, then pulverized with the suspension type pulverizer with the example 1, and crossed a 40-mesh sieve.

[0063] 2. Heating and wetting of materials: first prepare 0.1% sodium hydroxide solution, add sugarcane pith to make a 3% (g / v) suspension, and heat at 100°C for 10 minutes.

[0064] 3. Preparation of material suspension: add xanthan gum to the cane pith suspension to a concentration of 0.1%, stir and dissolve evenly, so that the cane pith is in a suspended state.

[0065] 4. Ultra-high pressure blasting: the sugarcane pith is subjected to ultra-high pressure bl...

Embodiment 3

[0070] 1, material drying, crushing: bagasse pretreatment is carried out by the method for embodiment 1, obtains the dry bagasse powder crossing 40 mesh sieves.

[0071] 2. Heating and moistening of materials: Prepare 0.5% sodium hydroxide solution, add bagasse to make a 3% (g / v) suspension, heat in a sterilizing pot at 125°C for 120 minutes, and then reduce the pressure to normal pressure (Temperature below 100°C) Take it out. Bagasse is in a state of easy suspension, and the solution is brown-black.

[0072] 3. Ultra-high pressure blasting: The material suspension is subjected to ultra-high pressure blasting with a high-pressure homogenizer, the method is the same as in Example 1, and the blasting pressure is 100 MPa. The processed material is viscous paste, dark brown.

[0073] 4. Material handling after blasting

[0074] Filter: carry out by the method for embodiment 1. The solid part (filter residue) obtained by filtration is solid, with a water content of 80% to 85%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com