Construction waste crushing device with dust collection function and method

A construction waste and crushing device technology, which is applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve problems affecting the service life of the crushing device, unsuitable waste particle size, and inhalation by staff, so as to reduce noise to The effects of external transmission, convenient switching, and smooth horizontal sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

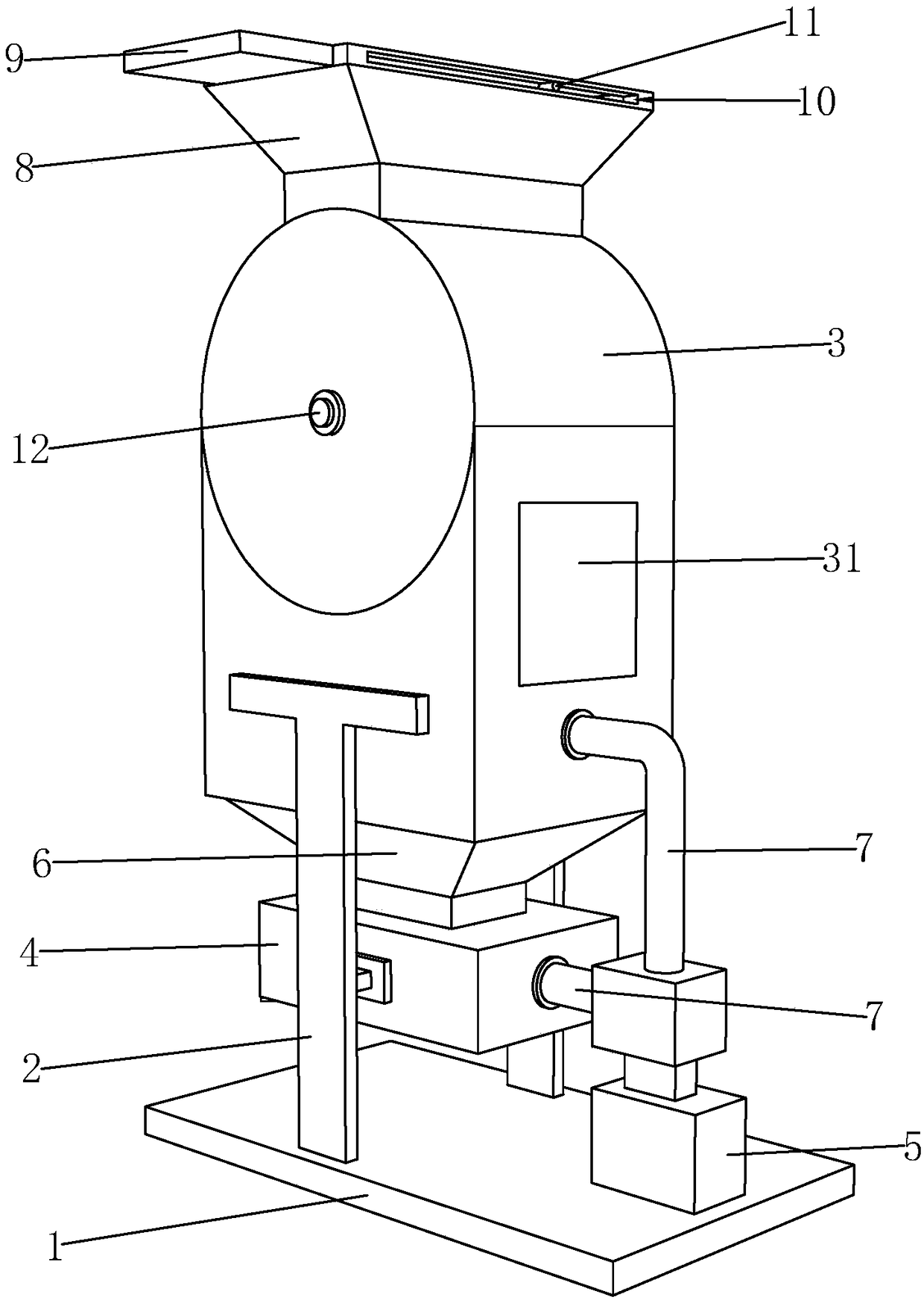

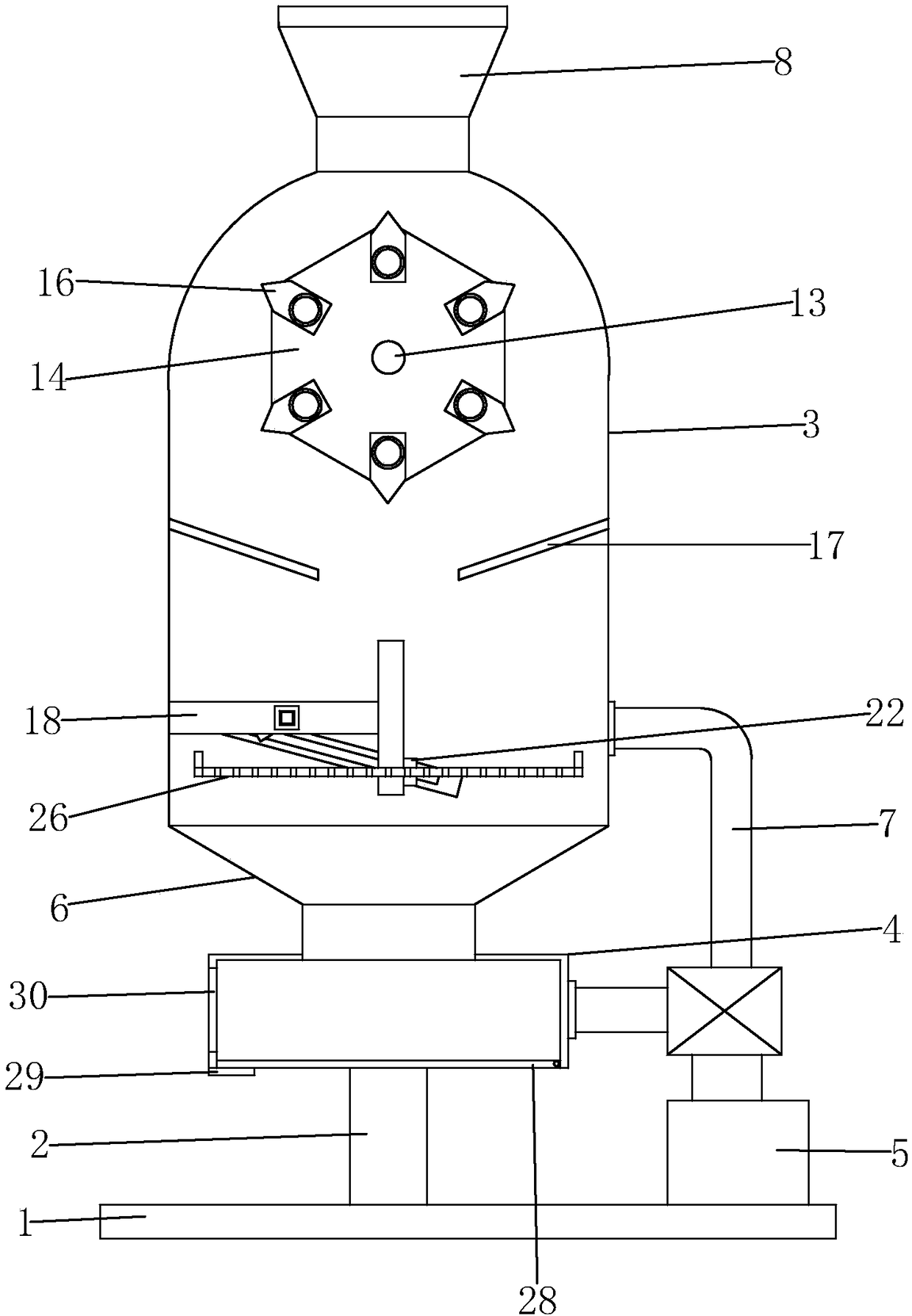

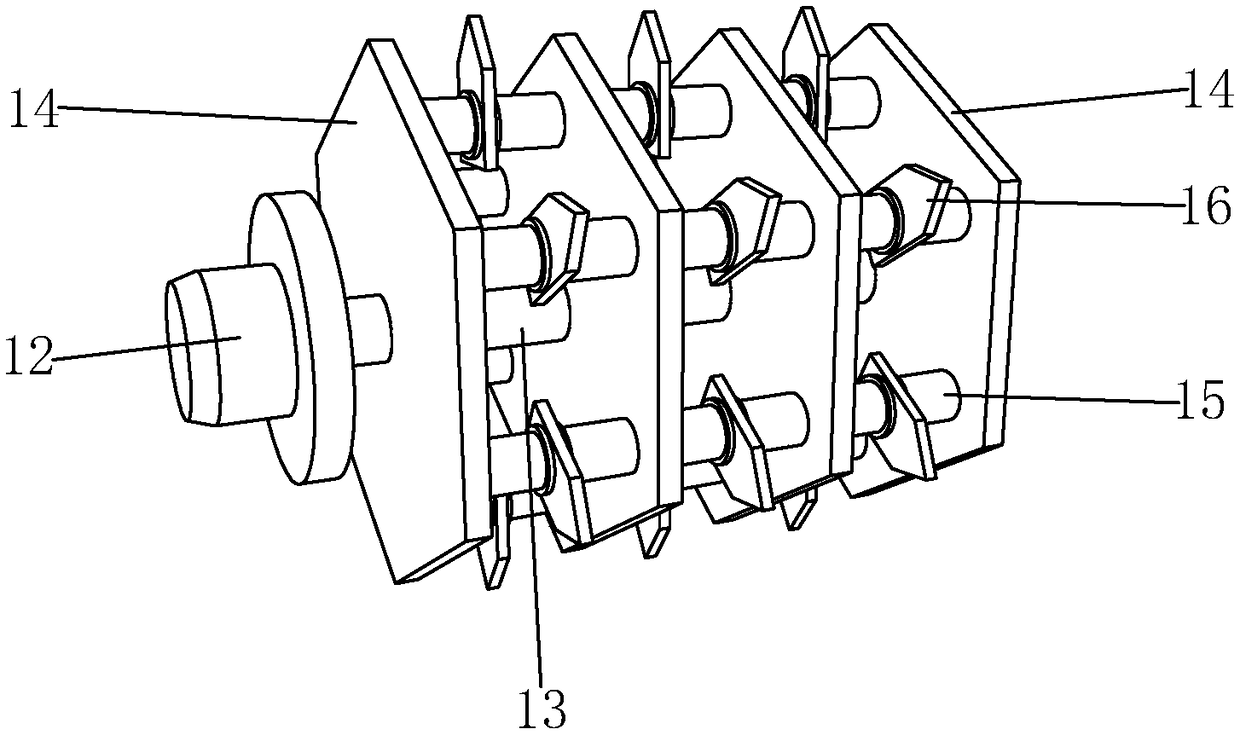

[0031] like Figure 1 to Figure 5As shown, it is a construction waste crushing device with dust suction function of the present invention, including a support base plate 1, a support frame 2, a crushing box 3, a static box 4 and a vacuum cleaner 5, and the static box 4 and the crushing box 3 are all located at A discharge hopper 6 is provided between the support frames 2, between the static box 4 and the crushing box 3, the vacuum cleaner 5 is set on the support base 1, and a dust suction pipe is provided between the vacuum cleaner 5, the crushing box 3, and the static box 4 7. The dust generated in the crushing box 3 and the resting box 4 is sucked into the vacuum cleaner 5 through the dust suction pipe 7, which reduces the adhesion of dust to the device components, reduces the impact on the service life of the device components, and eliminates the dust generated during the crushing process. The dust is removed in advance, so as to avoid the pollution of the dust to the atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com