Method for processing a workpiece made of hard metal for producing a tool main body

A hard metal and cutting tool technology, which is applied in the direction of metal processing machinery parts, control of workpiece feed movement, manufacturing tools, etc., can solve the problems of aggravated electrode wear and long time, and achieve the goal of improving dimensional stability and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

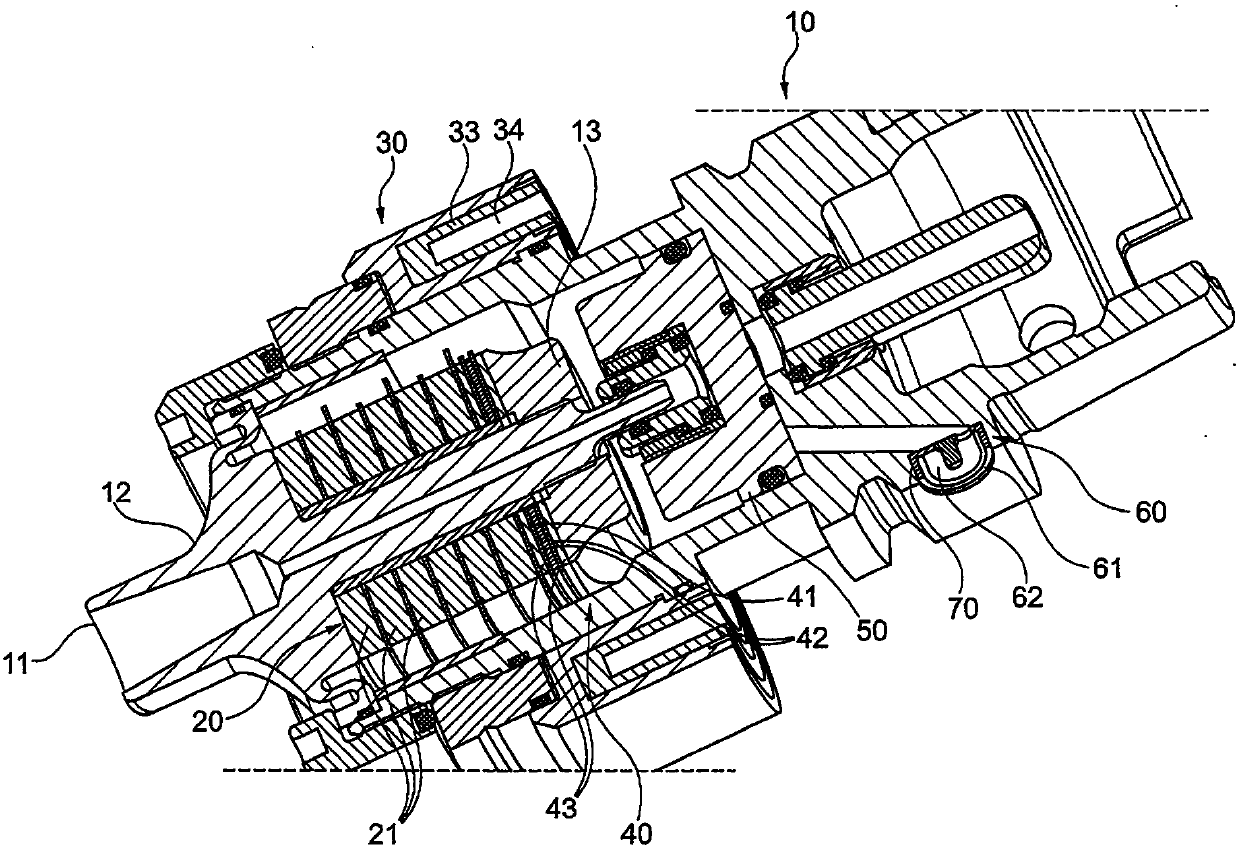

[0073] Examples and / or embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Identical or similar components in the drawings are designated herein with the same reference numerals, and sometimes also with different reference numerals.

[0074] However, it should be pointed out that the present invention is by no means limited or restricted to the embodiments described below and their structural features, but also includes variants of the embodiments, especially including the modification of the features of the examples described herein based on the scope of the independent claims of the present invention. Variations and / or combinations of single or multiple features of the examples described herein.

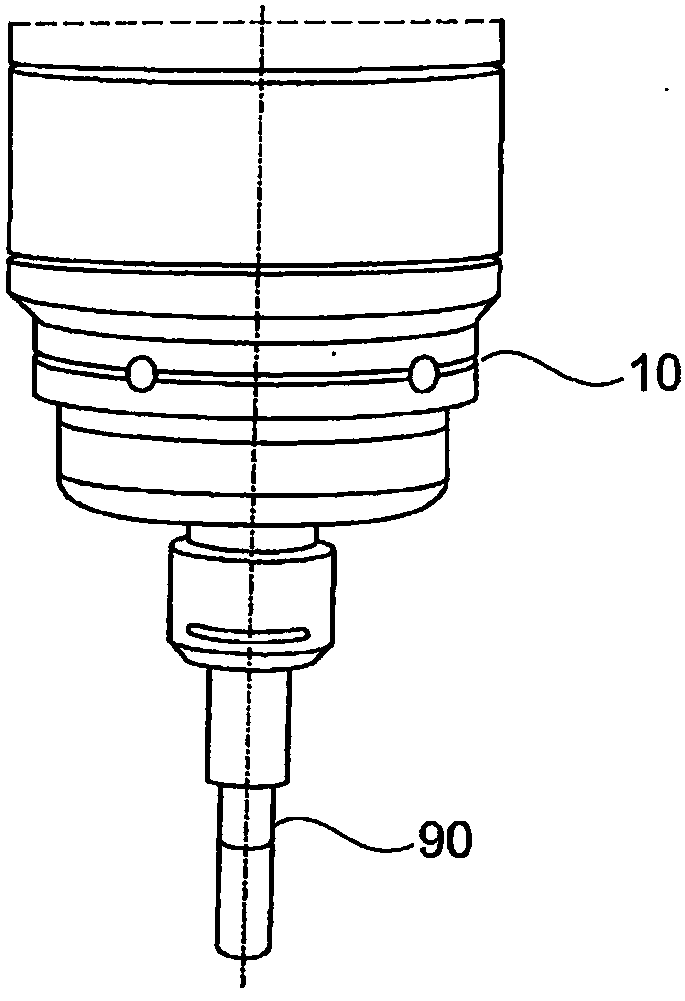

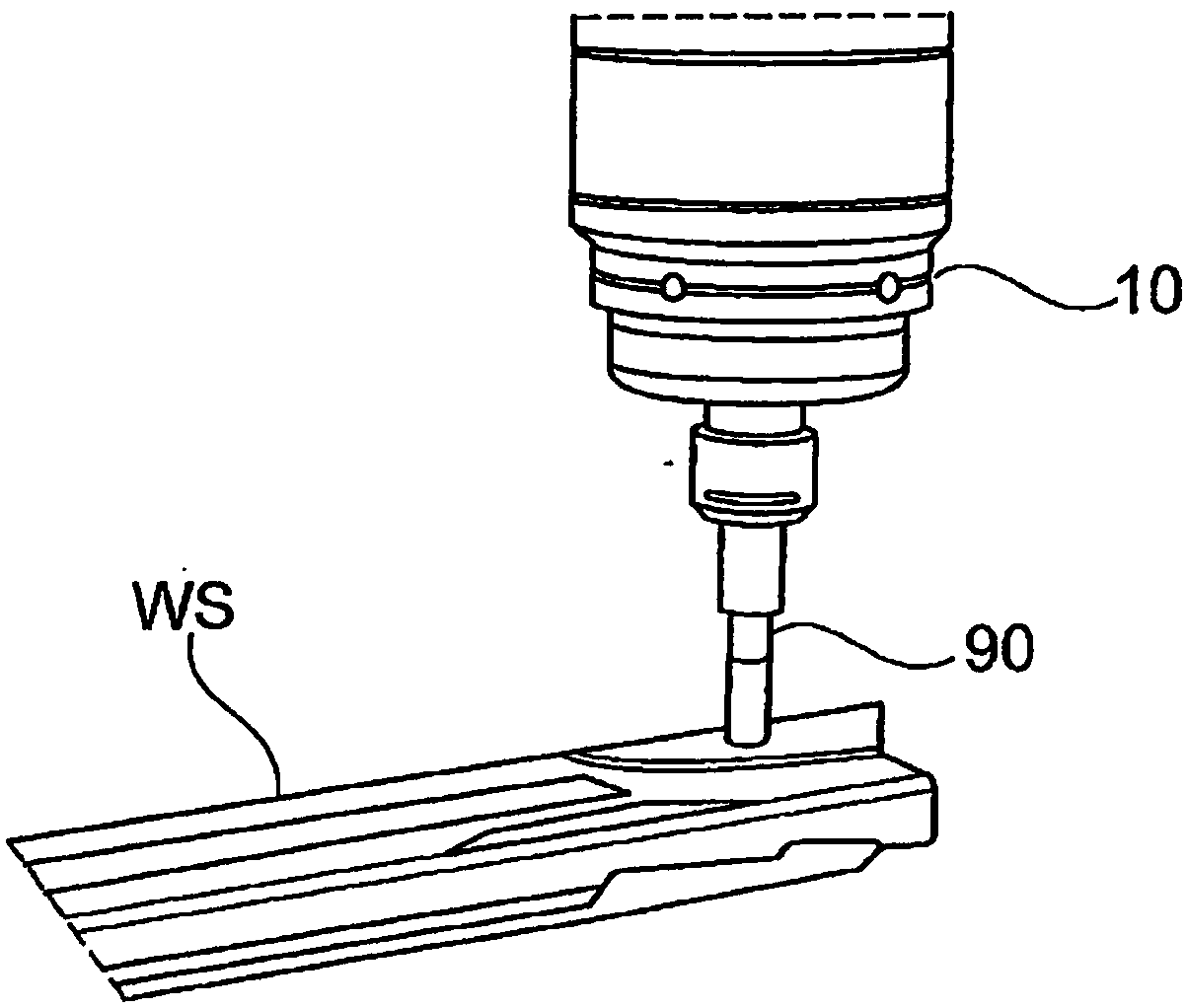

[0075] figure 1 Exemplary components of a tool holder 10 are shown by way of example, which may be used in the method according to the invention.

[0076] One end of the tool holder 10 includes a tool support 11 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com