Refuse landfill membrane concentration leachate treatment method

A landfill and treatment method technology, applied in the field of landfill membrane concentration leachate treatment, can solve the problems such as the difficulty of pollutant-enriched sewage treatment, and achieve disposal problems, harmless treatment, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

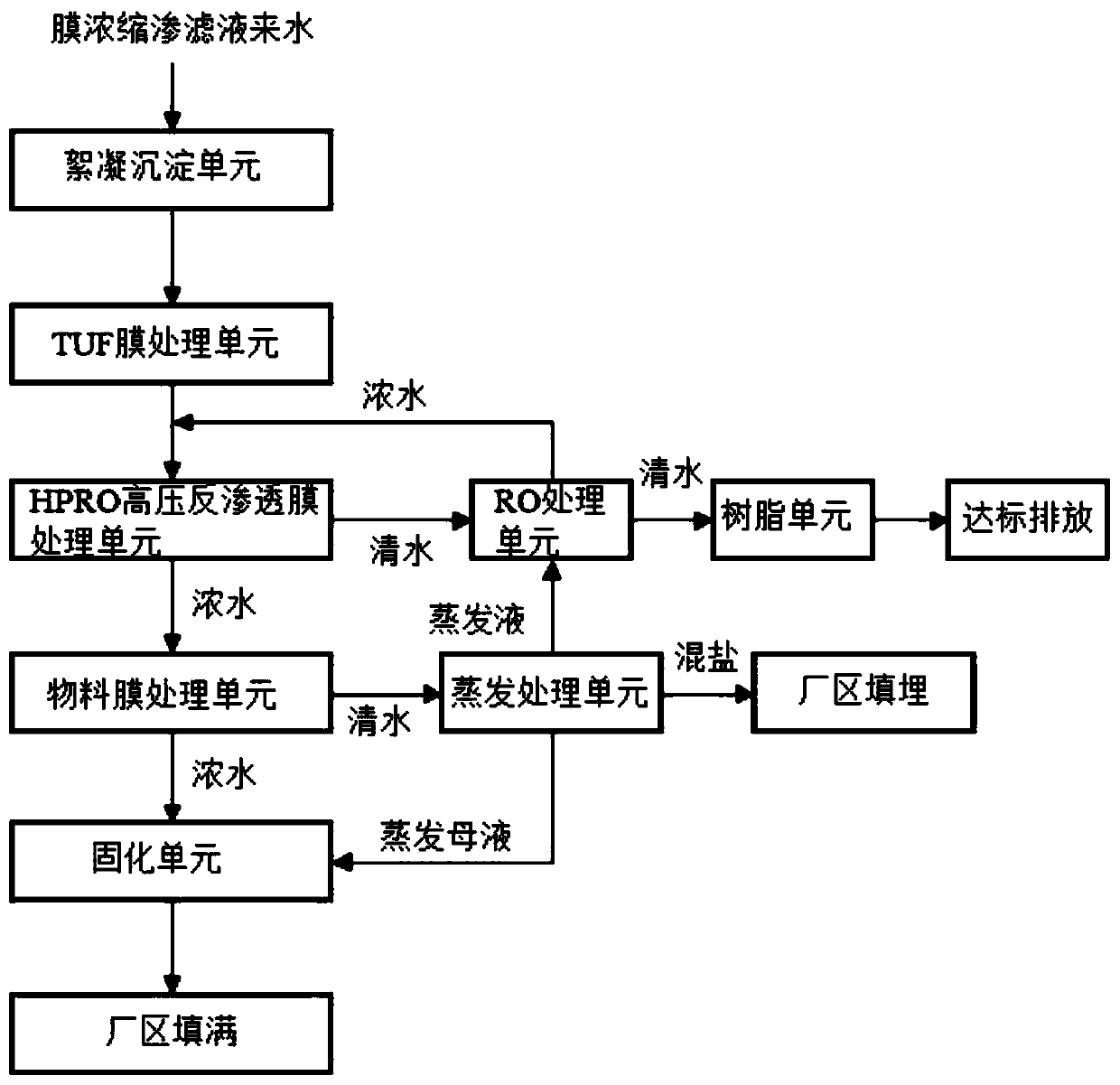

[0038] A waste landfill in Shandong has 83,000 cubic meters of membrane-concentrated leachate in stock. The COD of the membrane concentrate is 6000mg / L, the ammonia nitrogen is 1500mg / L, the total nitrogen is 2200mg / L, and the conductivity is 55000uS / cm. The current design is 300t / d treatment system. use as figure 1 As shown in the process flow chart, firstly, 0.1% calcium oxide, 0.2% PAC and 0.001% PAM are added to the flocculation sedimentation unit, and after 3 hours of reaction and precipitation, it enters the TUF membrane treatment unit. At this stage, the COD removal rate reaches 20%, ammonia nitrogen The removal rate reaches 10%, the total nitrogen removal rate reaches 15%, and the conductivity removal rate reaches 5%. The water produced by the TUF membrane treatment unit enters the HPRO high-pressure reverse osmosis membrane treatment unit. Its operating pressure is 120bar, the water production rate reaches 70%, the COD removal rate of the produced water reaches 90%, ...

Embodiment 2

[0041] A waste landfill in Jiangsu produces 100 tons of membrane-concentrated leachate per day. The COD of the membrane concentrate is 3280mg / L, the ammonia nitrogen is 1200mg / L, and the conductivity is 3640uS / cm. A 100t / d treatment system is now designed. use as figure 1 As shown in the process flow chart, firstly, 0.05% calcium oxide, 0.15% PAC and 0.002% PAM are added to the flocculation sedimentation unit, and after 2 hours of reaction and precipitation, it enters the TUF membrane treatment unit. At this stage, the COD removal rate reaches 15%, ammonia nitrogen The removal rate reaches 10%, the total nitrogen removal rate reaches 15%, and the conductivity removal rate reaches 5%. The water produced by the TUF membrane treatment unit enters the HPRO high-pressure reverse osmosis membrane treatment unit. Its operating pressure is 110bar, the water production rate reaches 75%, the COD removal rate of the produced water reaches 85%, the ammonia nitrogen removal rate reaches 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com