Microporous RTM (regenerative tissue matrix) as well as preparation and application thereof

A technology for regenerating tissue and micropores, which is applied in medical science and prostheses, can solve the problems of large three-dimensional structure of collagen fibers, reduce the survival rate of dermal matrix transplantation, and affect the structure of dermal matrix proteins, etc., and achieve uniform micropores. distribution, improving the quality of wound healing, and increasing the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

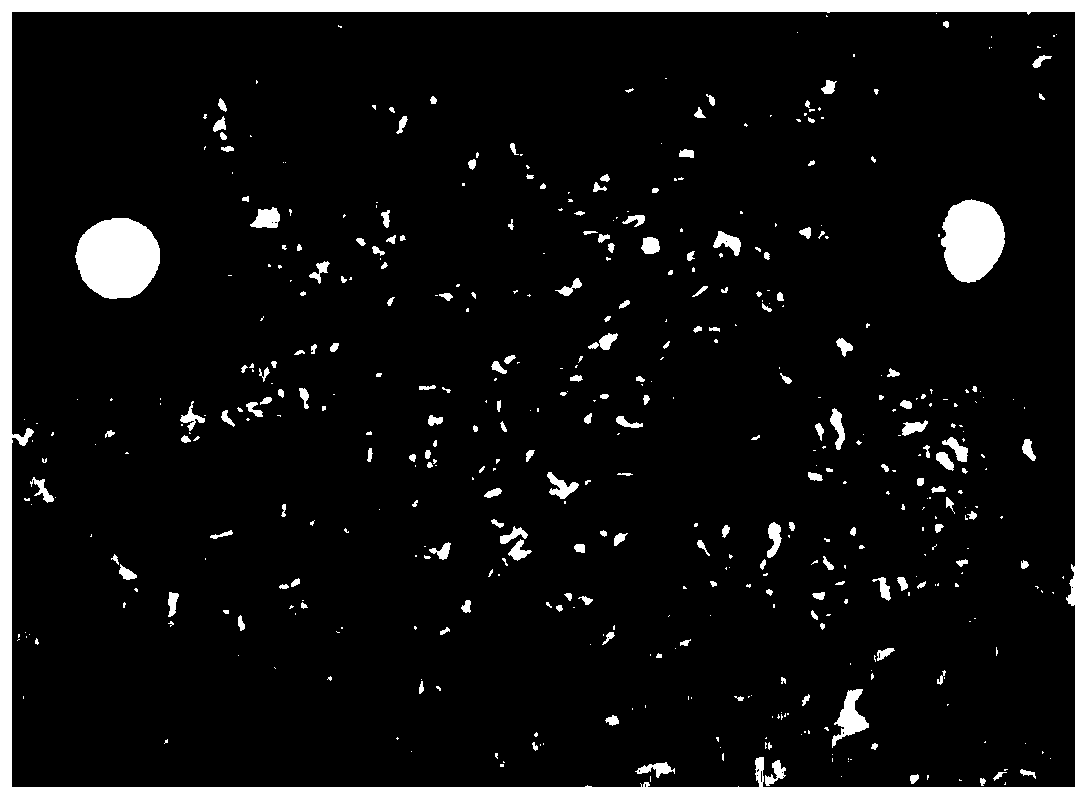

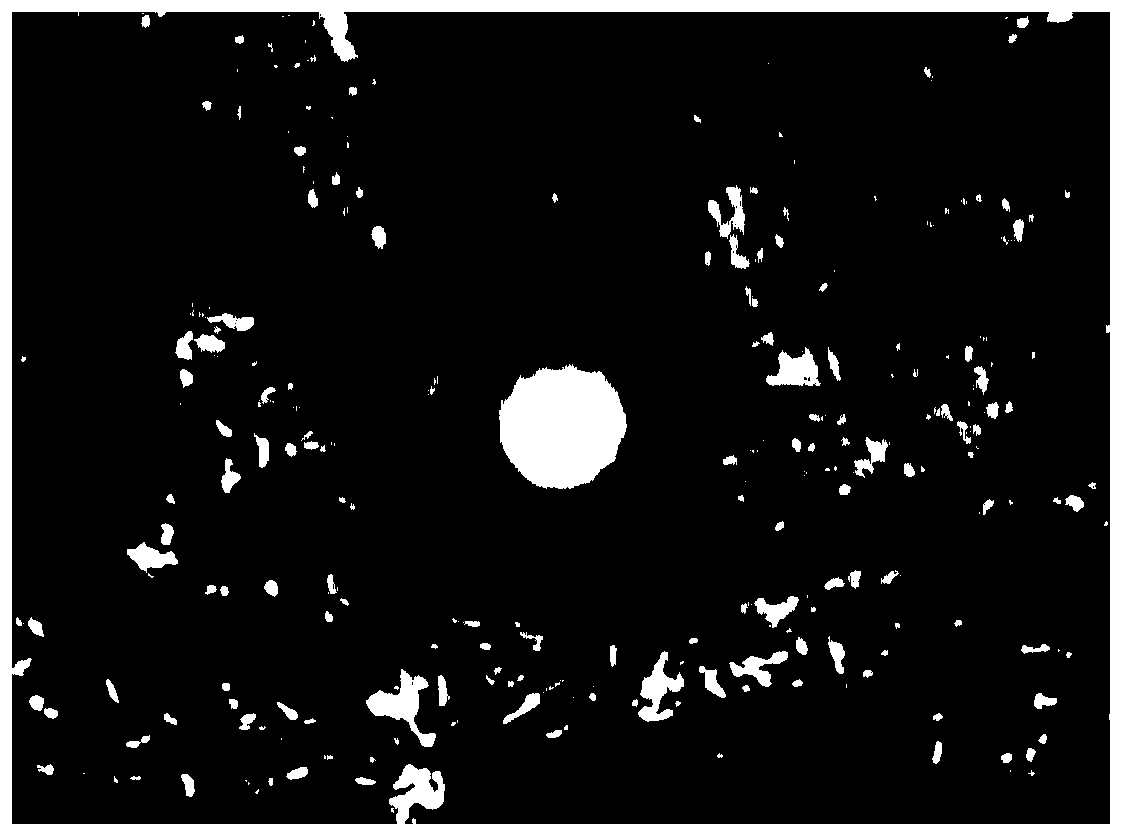

Image

Examples

Embodiment 1

[0046] The preparation method of the microporous regenerative tissue matrix of the present invention comprises the following steps:

[0047] 1. Washing: Take the allogeneic skin out of the storage protection solution, scrape off the subcutaneous tissue, put it into physiological saline and shake and wash it, the ratio of the area of the skin to the material-liquid of the physiological saline (cm 2 :mL) is 1:1, the total volume of feed liquid does not exceed 50% of the capacity of the shaking container, the shaking frequency is 30rpm, the shaking cleaning time is 1.5h, and the normal saline is replaced once every shaking for 0.5h, and a total of shaking and washing is done 3 times.

[0048] 2. Remove the epidermis: soak the allogeneic skin that has been shaken and washed in a 1mol / L NaCl solution, the ratio of solid to liquid (cm 2 : mL) at a ratio of 1:1, soak for 24 hours at 28°C. After soaking, the allogeneic skin is taken out, and the epidermis is torn off. The skin fro...

Embodiment 2

[0059] The preparation method of the microporous regenerative tissue matrix of the present embodiment comprises the following steps:

[0060] Step 1-5 is identical with embodiment 1;

[0061] 6. Rehydration treatment: Gradient-decreasing rehydration method is adopted, that is, the freeze-dried microporous allograft dermis is placed in 400 mmol / L trehalose low-concentration saline solution, and the solid-liquid ratio (cm 2 :ml) is 1:1, shake and soak for 15min; then take it out and add it to 200mmol / L trehalose low-concentration brine 2 :ml) is: 1:1, oscillating and soaking for 15min; 2 :ml) ratio: 1:1, shaking and soaking for 15 minutes, the microporous allogeneic dermis can be obtained.

[0062] 7. Alkaline expansion decellularization treatment: add microporous allogeneic dermis to 0.2mol / L Na 2 CO 3 Soaking treatment in medium, solid-liquid ratio (cm 2 :ml) 1:1, the total volume of the feed liquid does not exceed 50% of the oscillator capacity, the oscillation frequency...

experiment example 1

[0077] Experimental example 1: Performance testing of regenerative tissue matrix

[0078] Biological properties such as mechanical properties of the regenerated tissue matrix prepared in Examples 1 and 2 and Comparative Example 1 were tested, and the performance indicators included tensile strength, suture strength, and tensile elongation. The specific test results are shown in Table 1. The results show that the products of Examples 1 and 2 have a better fit to the skin, and have good toughness and elasticity, and can meet the requirements for the suture strength of the patch after removal of the giant mole.

[0079] Table 1 Test results of microporous regenerative tissue matrix

[0080] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com