Aflatoxin-effectively-removing peanut oil extracting method

A kind of technology of aflatoxin and extraction method, which is applied in the field of biochemistry, can solve the problems of increased peroxide value of peanut oil, decreased peroxide value of peanut oil, susceptibility to infection by Aspergillus flavus, etc., and achieves long ultraviolet irradiation time and improved Fragrance and oil yield, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

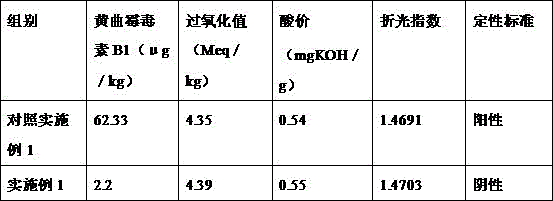

Examples

Embodiment 1

[0036] A kind of peanut oil extraction method that effectively removes aflatoxin, is characterized in that, comprises the steps:

[0037] 1 peanut stock preparation

[0038] Sampling inspection of peanut raw materials, such as water impurities, aspergillus flavus, acid value, peroxidant, oil content and other indicators, and making records; after passing the test, it will be received and put into storage.

[0039] 2 crude oil

[0040] Peanut raw materials and 20% (mass fraction) citric acid aqueous solution are mixed in a weight ratio of 1:4, soaked at 50-60°C for 40-50 minutes, then coarsely pulverized with a tissue grinder, then finely pulverized with a colloid mill and passed A 50-80 mesh sieve removes large particles and fibers to obtain a peanut raw material pretreatment mixture. This prevents them from settling to the bottom of the reactor after heating to overheat and burn and cause odors.

[0041] Crude oil is obtained by pressing the pretreated peanuts

[0042] 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com