Pretreatment method for improving enzyme hydrolysis rate of lignocellulose

A technology of lignocellulose and enzymatic hydrolysis, applied in fermentation and other directions, can solve the problem of unsatisfactory cellulosic hydrolysis rate and achieve clean and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0030] The wood powder raw material in this example is fast-growing triploid Populus tomentosa, three-year-old, collected from Shandong Province. After the raw material is crushed, pass through a 0.8mm sieve, extract with phenyl alcohol Soxhlet in a volume ratio (2:1) for 6 hours, and take a dewaxed 80-100 mesh dry sample for use. Ionic liquid [C 2 mim]OAc was purchased from Lanzhou Institute of Chemical Physics with a purity of ≥98.5%. Cellulase (Celluclast 1.5L) and β-glucosidase were purchased from Sigma Aldrich. All other reagents used were of analytical grade or reagent grade and were directly purchased and used without further purification.

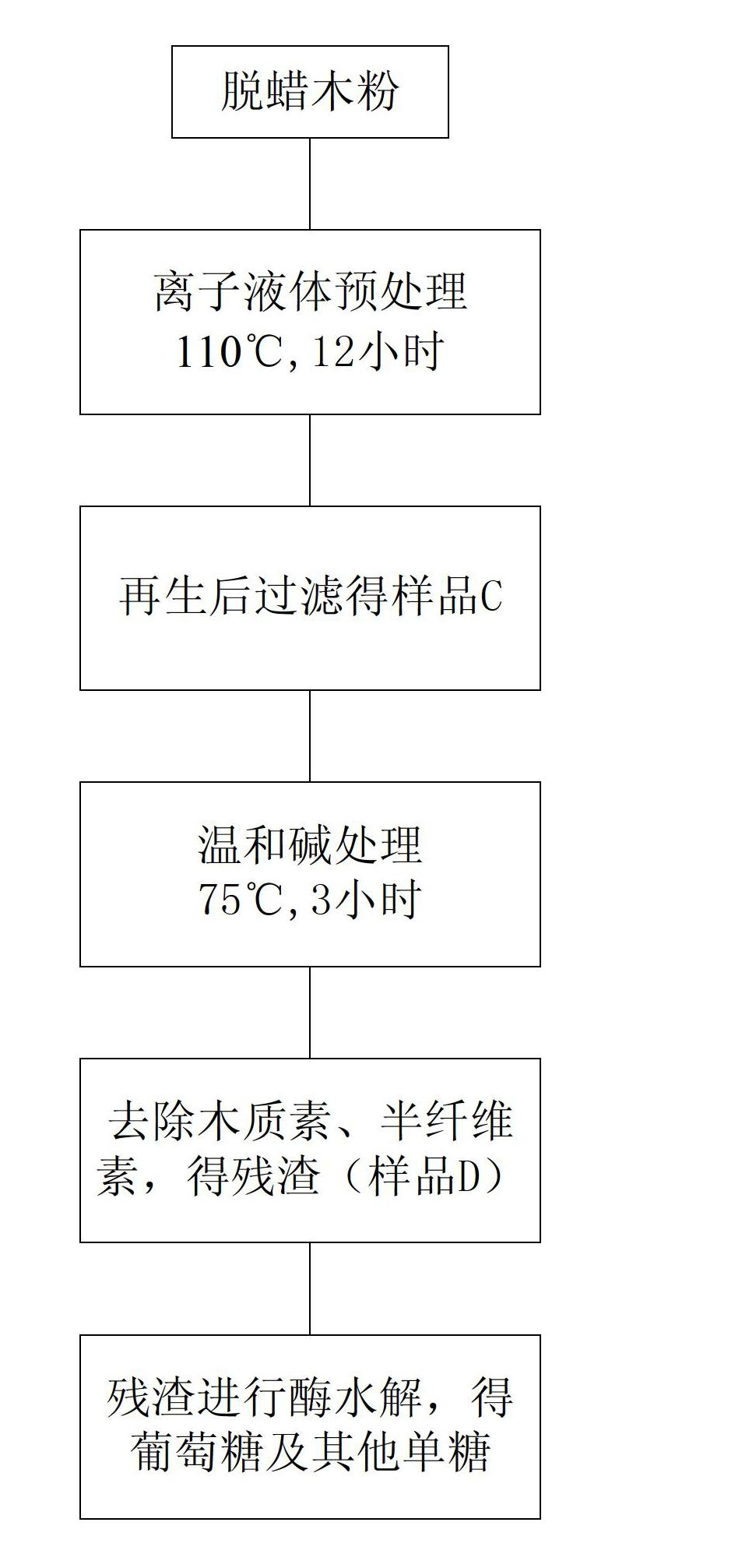

[0031] figure 1 It is a schematic flow chart of the lignocellulose pretreatment method for improving the enzymatic hydrolysis rate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com