Method for efficiently separating lignin

A lignin and high-efficiency technology, used in textiles and papermaking, pulping with organic solvents, fiber raw material processing, etc., can solve problems such as inability to obtain relevant structural information, and achieve the effect of improved yield, clean and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0033] The wood powder raw material in this example is fast-growing triploid Populus tomentosa, three-year-old, collected from Shandong Province. The raw materials are crushed and passed through a 0.8mm sieve, extracted with phenylalcohol at a volume ratio (2:1) for 6 hours, and dried samples of 80-100 mesh are taken after dewaxing for use. Ionic liquid [C 2 mim]OAc was purchased from Lanzhou Institute of Chemical Physics with a purity of ≥98.5%. Cellulase (Celluclast 1.5L) and β-glucosidase were purchased from Sigma Aldrich. All other reagents used were of analytical grade or reagent grade and were directly purchased and used without further purification.

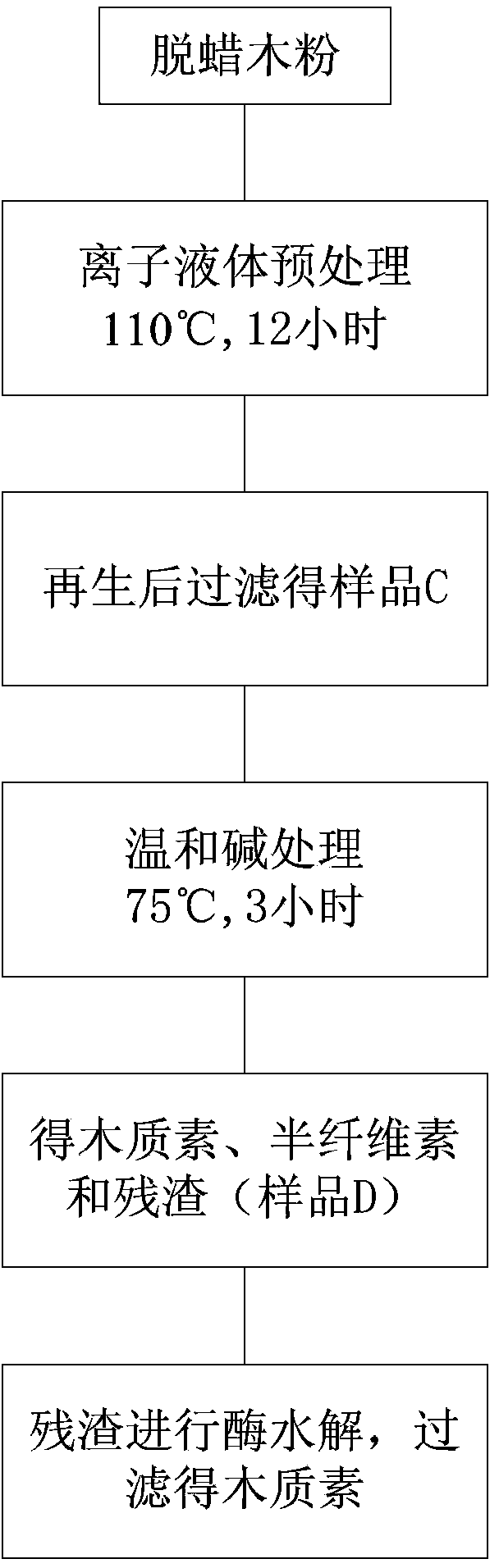

[0034] figure 1 It is a schematic flow chart of the method for efficiently separating lignin of the present invention. Such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com