Method for preparing 5'-nucleotides using malt root complex phospho-esterase

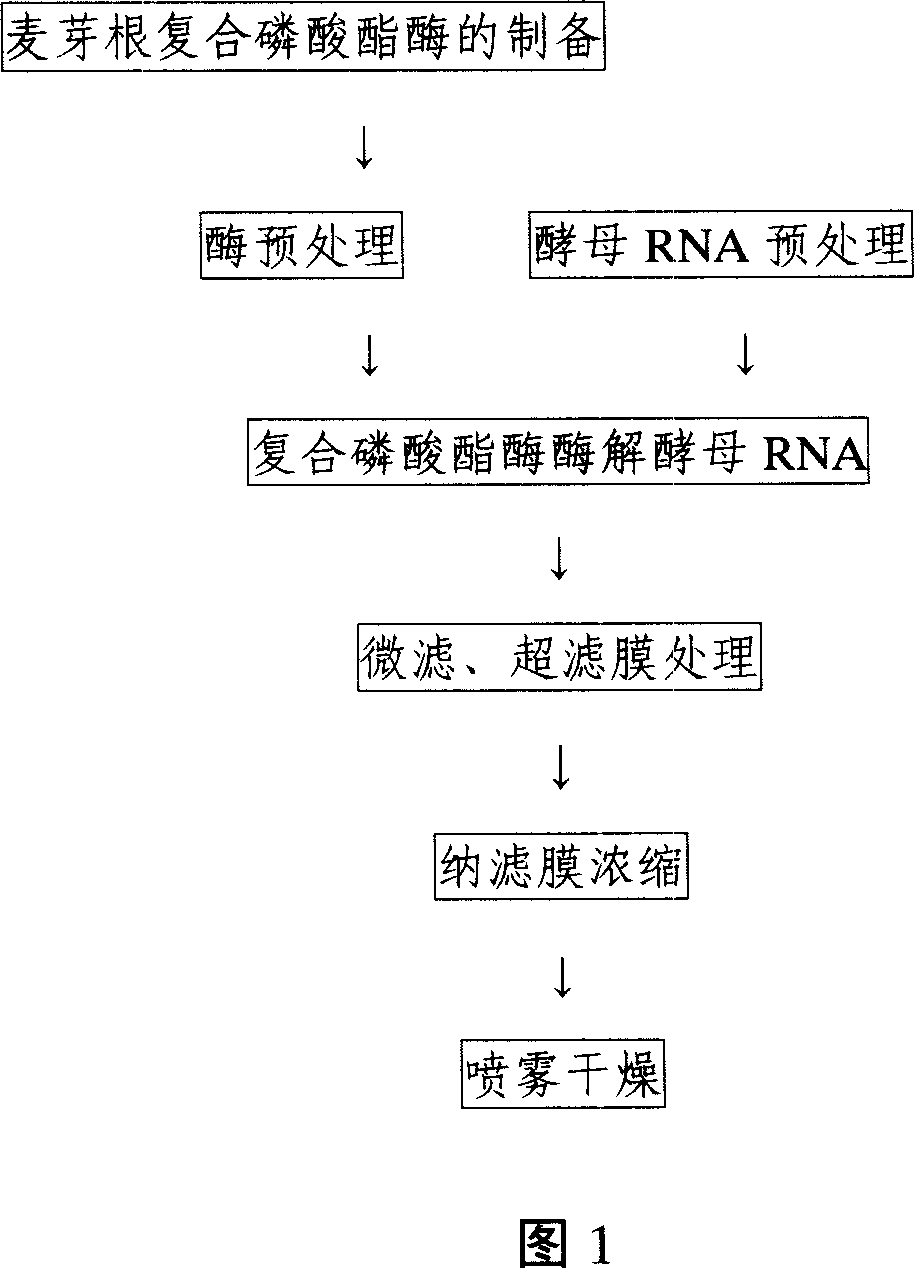

A technology of compound phosphatase and malt root, applied in the biological field, can solve the problems of insufficient research, low nucleotide yield, low product purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Pretreatment and enzymatic hydrolysis

[0024] ①Pretreatment: liquid RNA, in OD 260 Absorbance calculation OD 260 The reading is 0.375×2000 (representing the reading after diluting the liquid RNA by 2000 times, the same below), which is equivalent to feeding 3750g of pure RNA, adjusting the pH to 9.0; 6kg of malt root, adding 60L of water, crushing in a colloid mill, extracting for 4 hours, and centrifuging to obtain the enzyme solution 40L. Heat the RNA solution to 93°C, heat the enzyme solution to 40°C for later use;

[0025] ②Enzymolysis conditions: After mixing the enzyme solution and RNA, control the temperature at 74°C, pH 5.2, the final concentration of RNA at 2.5%, the final enzyme activity of 120u / ml, and keep warm for 2 hours;

[0026] ③ Termination reaction: After the enzymatic hydrolysis is completed, raise the temperature to 90°C-100°C and keep it warm for 30 minutes;

[0027] ④Methamidophos: 5'-nucleotide 21mg / ml, enzymolysis rate 84%;

[0028] 2. ...

Embodiment 2

[0034] 1. Pretreatment and enzymatic hydrolysis

[0035] ①Pretreatment: liquid RNA, in OD 260 Absorbance calculation OD 260 The reading is 0.453×2000, which is equivalent to feeding 3500g of pure RNA, adjusting the pH to 9.0; adding 70L of water to 7kg of malt root, crushing in a colloid mill, extracting for 4h, and centrifuging to obtain 55L of enzyme solution. Heat the RNA solution to 95°C, heat the enzyme solution to 40°C for later use;

[0036] ②Enzymolysis conditions: After mixing the enzyme solution and RNA, control the temperature at 72°C, pH 5.2, the final concentration of RNA at 2.5%, the final enzyme activity of 100u / ml, and keep warm for 2 hours;

[0037] ③ Termination reaction: After the enzymatic hydrolysis is completed, raise the temperature to 90°C-100°C and keep it warm for 30 minutes;

[0038] ④Methamidophos: 5'-nucleotide 18mg / ml, enzymolysis rate 72.8%;

[0039] 2. Microfiltration: Inorganic ceramic membrane is used to separate the solid and liquid of th...

Embodiment 3

[0045] 1. Pretreatment and enzymatic hydrolysis

[0046] ①Pretreatment: liquid RNA, in OD 260 Absorbance calculation OD 260 The reading is 0.412×2000, which is equivalent to feeding 3000g of pure RNA, adjusting the pH to 8.0; 8kg of malt root, adding 100L of water, crushing in a colloid mill, extracting for 8h, and centrifuging to obtain 70L of enzyme solution. Heat the RNA solution to 70°C, heat the enzyme solution to 30°C for later use;

[0047] ②Enzymolysis conditions: After mixing the enzyme solution and RNA, control the temperature at 65°C, pH 4.5, the final RNA concentration of 2.0%, the final enzyme activity of 150u / ml, and keep warm for 3 hours;

[0048] ③ Termination reaction: After the enzymatic hydrolysis is completed, raise the temperature to 90°C-100°C and keep it warm for 30 minutes;

[0049] ④Methamidophos: 5'-nucleotide 15.3mg / ml, enzymolysis rate 76.7%;

[0050] 2. Microfiltration: Inorganic ceramic membrane is used to separate the solid and liquid of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com