Method for preparing sericin polypeptides with aqueous enzymatic method

The technology of sericin and water enzymatic method is applied in the field of biotechnology polypeptide preparation, which can solve the problems of polluted protein, amino acid damage, difficult control of hydrolyzed molecular weight, etc., and achieve the effects of low cost, simple process and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 6g of sericin protein to 94g of water, adjust the pH of the reaction solution to 8 with 1mol / L sodium hydroxide aqueous solution, add 0.02g of Alcalase2.4L alkaline protease, raise the temperature to 60°C, and maintain the pH=8 for 1 hour after enzymolysis, Use 1mol / L hydrochloric acid to adjust the pH of the reaction solution to 7, add 0.015g AS1398 neutral protease, and enzymolyze at 50°C, pH=7 for 1 hour; then inactivate at 85°C for 20 minutes, centrifuge, take the supernatant, and concentrate , freeze-drying to obtain 5.39g sericin polypeptide. The amino acid composition before and after enzymolysis is shown in Table 1. The relative molecular mass distribution of the enzymolysis products is shown in Table 2:

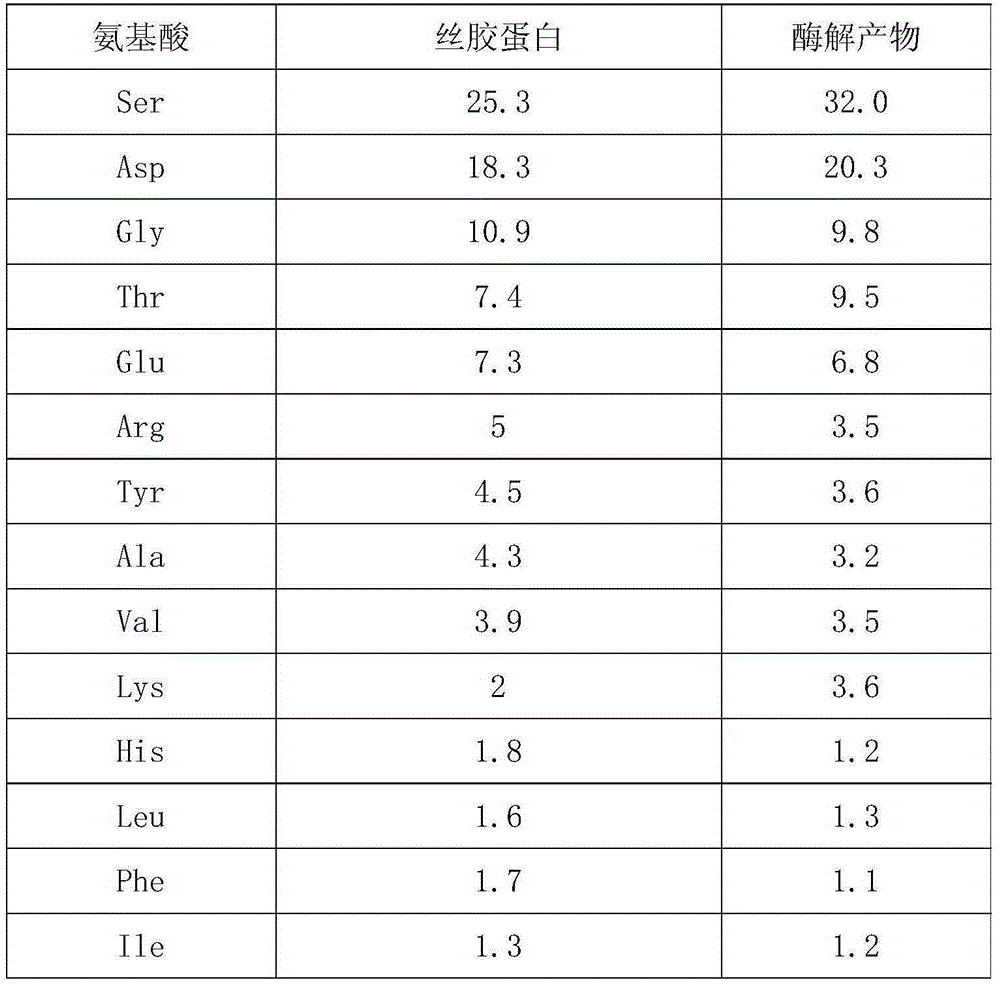

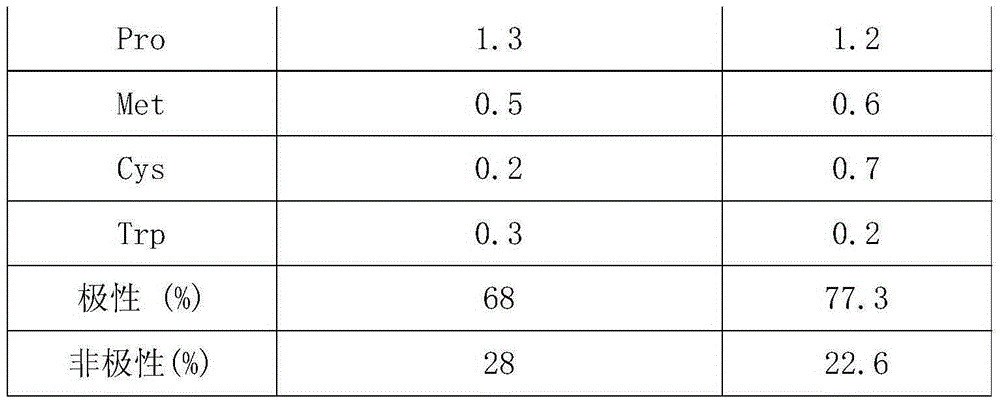

[0016] Amino acid composition (g / 100g protein) before and after enzymolysis of table 1

[0017] amino acid

Enzyme hydrolyzate

Ser

25.3

32.5

Asp

18.3

20.5

Gly

10.9

9.9

Thr

7.4...

Embodiment 2

[0021] Add 4g of sericin to 96g of water, adjust the pH of the reaction solution to 8.5 with 1mol / L sodium hydroxide aqueous solution, add 0.03g of Alcalase2.4L alkaline protease, raise the temperature to 55°C, and maintain the pH = 8.5. After 1.5 hours of enzymolysis, Use 1mol / L hydrochloric acid to adjust the pH of the reaction solution to 7, add 0.016g AS1398 neutral protease, and enzymolyze at 45°C, pH=7 for 1.5 hours; then inactivate at 80°C for 30 minutes, centrifuge, take the supernatant, and concentrate , freeze-drying to obtain 3.36g sericin polypeptide. The amino acid composition before and after enzymolysis is shown in Table 3, and the relative molecular mass distribution of the enzymolysis products is shown in Table 4:

[0022] Amino acid composition (g / 100g protein) before and after enzymolysis of table 3

[0023] amino acid

Sericin

Enzyme hydrolyzate

Ser

25.3

33.2

Asp

18.3

20.1

Gly

10.9

10.3

Th...

Embodiment 3

[0027] Add 7g of sericin to 93g of water, adjust the pH of the reaction solution to 9 with 1mol / L sodium hydroxide aqueous solution, add 0.04g of Alcalase2.4L alkaline protease, raise the temperature to 65°C, and maintain the pH=9 for 2 hours after enzymatic hydrolysis, Use 1mol / L hydrochloric acid to adjust the pH of the reaction solution to 7, add 0.018g AS1398 neutral protease, enzymolyze at 55°C, pH=7 for 2 hours; then inactivate at 90°C for 40 minutes, centrifuge, take the supernatant, and concentrate 1. Freeze-drying to obtain 6.43g sericin polypeptide. The amino acid composition before and after enzymolysis is shown in Table 5, and the relative molecular mass distribution of the enzymolysis product is shown in Table 6:

[0028] Amino acid composition (g / 100g protein) before and after enzymolysis of table 5

[0029]

[0030]

[0031] Table 6 Relative molecular mass distribution of enzymatic hydrolysis products

[0032] relative molecular mass

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com