Lignocellulose pretreatment method for increasing enzyme hydrolysis rate by oxidation removal of lignin

A lignocellulose and pretreatment technology, applied in the direction of fermentation, etc., can solve the problems of less research literature, destroy the recalcitrant structure of biomass, destroy the crystal structure, etc., and achieve the improvement of xylose yield, simple and easy operation, clean and efficient separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

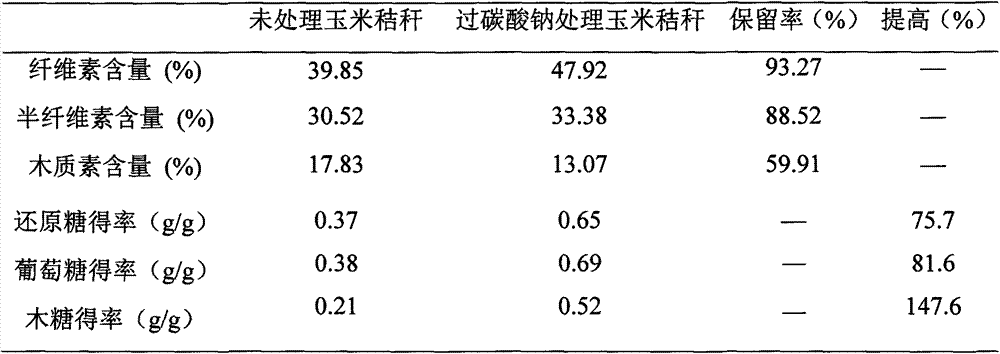

Embodiment 1

[0015] A pretreatment method for increasing the enzymatic hydrolysis rate of corn stalk raw materials by oxidative delignification, comprising the following steps:

[0016] (1) Crush the corn stalks, pass through a 60-mesh sieve and dry at 90°C until constant weight.

[0017] (2) Take 10 g of crushed and dried corn stalk raw material, add 100 mL of 4% (w / v) sodium percarbonate solution, and treat at 60° C. for 4 h.

[0018] (3) Filter the pretreated corn stalks, wash with distilled water until the pH of the filtrate reaches neutral, and dry at 90° C. to constant weight.

[0019] (4) Take 2.0 g of the dried corn stalk residue (or corn stalk raw material without pretreatment) after the above-mentioned pretreatment, add 25 mL of 0.05 mol / L, pH to 4.8 citric acid buffer solution, add to the mixture Add commercial cellulase and xylanase derived from Trichoderma, wherein the loading of cellulase is 30FPU / g substrate, and the loading of xylanase is 8000U / g substrate, and the total v...

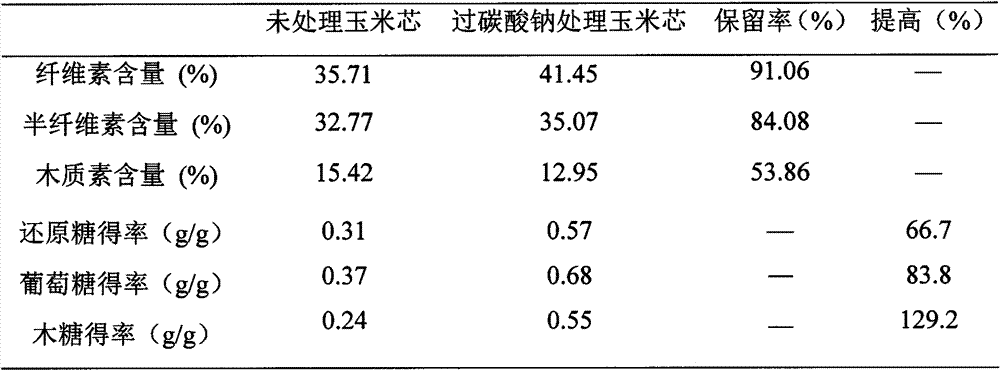

Embodiment 2

[0024] A pretreatment method for improving enzymatic hydrolysis rate of corn cob raw material by oxidative delignification, comprising the following steps:

[0025] (1) The corncob raw material was crushed, passed through an 80-mesh sieve, and then dried at 90°C to constant weight.

[0026] (2) Take 10 g of crushed and dried corn cob raw material, add 100 mL of 5% (w / v) sodium percarbonate solution, and treat at 50° C. for 6 h.

[0027] (3) Filter the pretreated corncobs, wash with distilled water until the pH of the filtrate reaches neutrality, and dry at 90° C. to constant weight.

[0028] (4) Take 2.0 g of the dried corncob residue (or corncob raw material without pretreatment) after the above-mentioned pretreatment, add 25mL of 0.05mol / L, pH to 4.8 citric acid buffer solution, add to the mixture Add commercial cellulase and xylanase derived from Trichoderma, wherein the loading amount of cellulase is 40FPU / g substrate, and the loading amount of xylanase is 10000U / g substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com