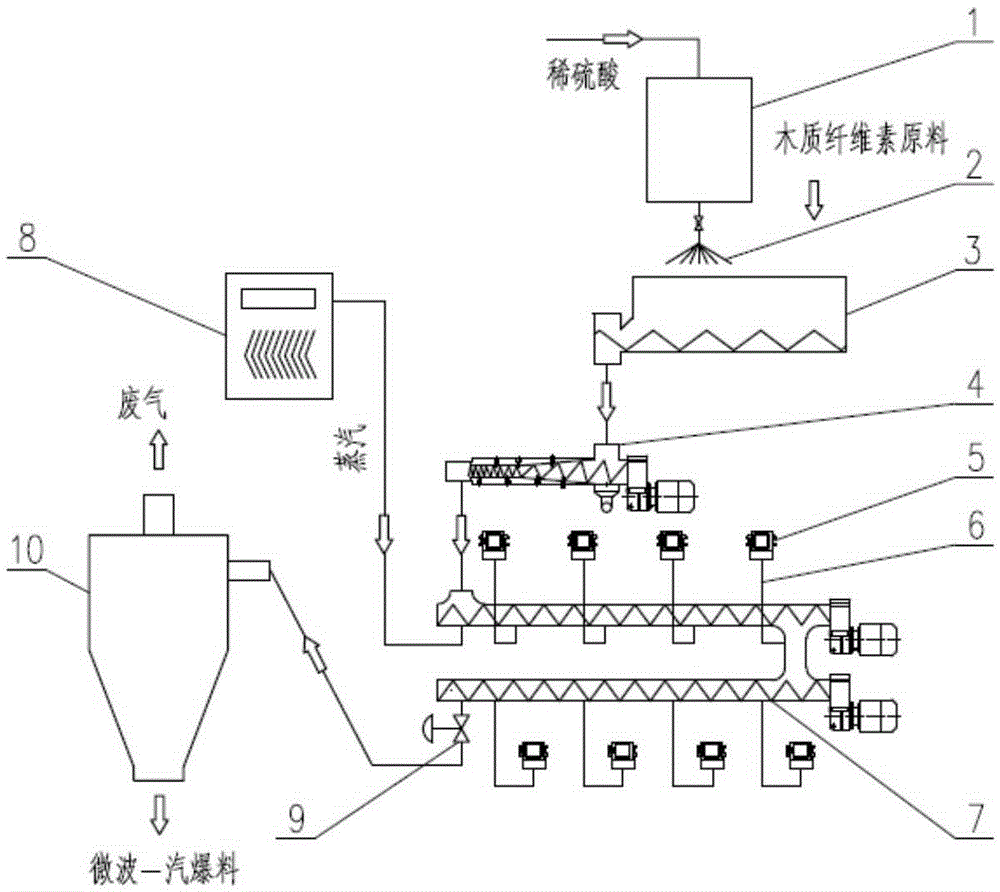

Device and method for performing continuous pretreatment on lignocellulose material by utilizing microwave-diluted acid steam explosion

A lignocellulosic and pretreatment technology, applied in biomass pretreatment, enzymatic/microbiological devices, biomass post-treatment, etc., can solve problems such as low efficiency, large environmental load, and utilization rate of less than 3%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The straw with a particle size of 1-30cm is transported to the feeder, and at the same time, the dilute sulfuric acid with a concentration of 0.5% in the dilute acid tank is continuously sprayed on the material through the spray valve, and the mass ratio of the dilute acid spray amount to the straw is 8 :1, to impregnate the lignocellulose. The dilute sulfuric acid remaining at the bottom of the stalks and not impregnated into the stalks is filtered through the screen below the booster screw device, and returned to the dilute acid tank for recycling. After that, the material enters the pressurized screw device, where the straw is further pulverized by kneading, the moisture content of the straw is reduced to about 60% by extrusion and the impregnation process is accelerated, and the steam back spray of the reaction retainer is prevented by variable diameter pressurization. The entire impregnation time is about 5 minutes, and the pressure at the end of the booster screw ...

Embodiment 2

[0030]The straw with a particle size of 1-30cm is transported to the feeder, and at the same time, the dilute sulfuric acid with a concentration of 3% in the dilute acid tank is continuously sprayed on the material through the spray valve, and the mass ratio of the dilute acid spray amount to the straw is 6 :1, to impregnate the lignocellulose. The dilute sulfuric acid remaining at the bottom of the stalks and not impregnated into the stalks is filtered through the screen below the booster screw device, and returned to the dilute acid tank for recycling. After that, the material enters the pressurized screw device, where the straw is further pulverized by kneading, the moisture content of the straw is reduced to about 60% by extrusion and the impregnation process is accelerated, and the steam back spray of the reaction retainer is prevented by variable diameter pressurization. The entire impregnation time is about 5 minutes, and the pressure at the end of the booster screw dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com