Method for preparing manganese sulfate by biomass self-heating reduction of low grade manganese oxide ore

A technology of manganese oxide ore and biomass raw materials, applied in the direction of manganese sulfate, energy input, etc., can solve the problems that manganese sulfate solution cannot be produced by electrolytic manganese, and the manganese leaching rate is low, so as to reduce production costs and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Get Tiandeng manganese oxide ore powder 800Kg and grind to 10 mesh rice straw 200Kg and mix, then with 10Kg initiation additive (firewood coal (containing C content is 60% w / w, pulverized to 80 mesh): pyrite (containing S content is 42% w / w, crushed to 80 mesh): potassium nitrate: potassium phosphate = 20: 10: 5: 1) mix evenly, put the uniformly mixed material in the reaction furnace, roast at 600°C for 1h, and roast well The material is cooled to below 80°C, and the obtained calcined sand is leached at 60°C for 60 minutes with dilute sulfuric acid (acid-mineral ratio: 0.55) with a concentration of 98 g / L (1mol / L), and the pH of the mixture is adjusted to 6.0 with ammonia water. , filtered, and a small amount of water to wash the filter residue, and the manganese leaching rate was calculated to be 95.3%. The obtained filtrate can meet the requirements for the production of electrolytic manganese, manganese dioxide, trimanganese tetraoxide and other products after remova...

Embodiment 2

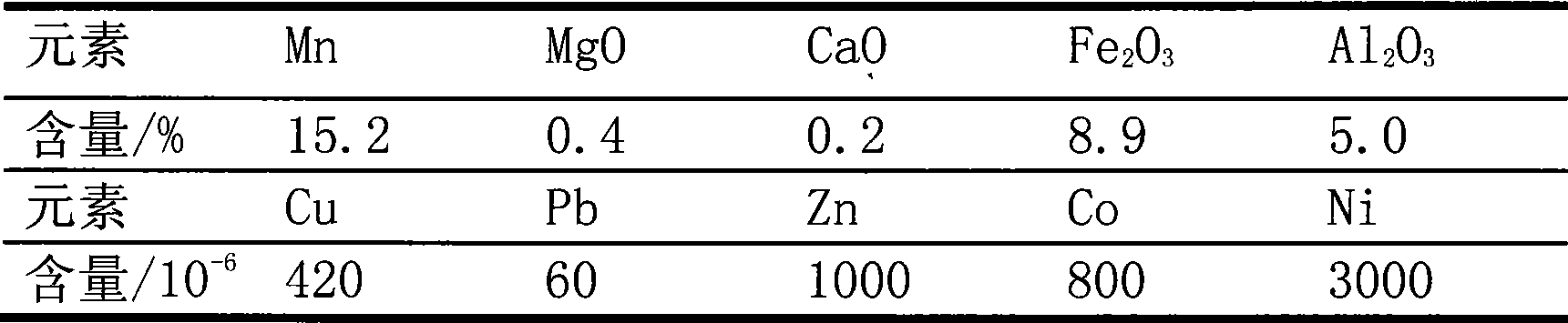

[0034]Get 600Kg of Laibin manganese oxide ore powder and mix it with 60Kg of wheat straw crushed to 10 mesh, and then mix it with 6Kg of initiation additive (coal gangue (with C content of 25% w / w, S content of 2% w / w, crushed to 80 mesh) : Sodium nitrate: Sodium phosphate=50:5:0.5) Mix evenly, put the uniformly mixed material in the reaction furnace, roast at 400°C for 3 hours, cool the roasted material to below 80°C, the obtained calcined sand has a concentration of Dilute sulfuric acid (acid-mineral ratio: 0.55) of 98 g / L (1mol / L) at 40°C for 120 min, adjust the pH of the mixture to 2.5 with sodium hydroxide, filter, wash the filter residue with a small amount of water, and calculate manganese The leaching rate is 98.3%. The obtained filtrate was precipitated with MnS and cobalt-nickel in an amount of 1.1 times the molar content of cobalt-nickel in the solution, and filtered to obtain a filter cake, which was dried to obtain a cobalt-nickel enrichment with a cobalt content ...

Embodiment 3

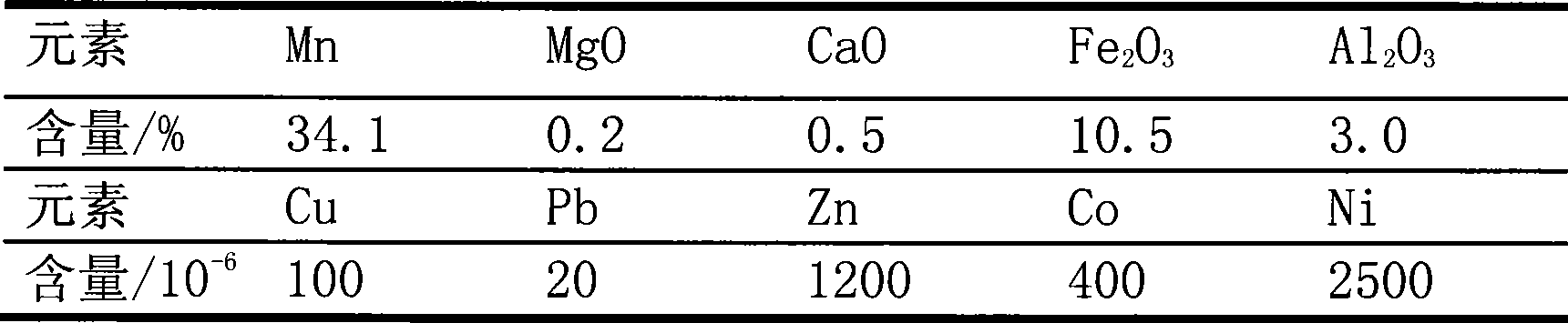

[0036] Get Gongcheng manganese oxide ore powder 1000Kg and grind to 20 mesh sawdust 100Kg and crush to 20 mesh bagasse 100Kg and mix, then with 8Kg initiator additive (brignite (containing C content is 70% w / w, crushed to 100 mesh): sulfuric acid Ferrous: Potassium nitrate: Phosphorus; Potassium acid = 50:1:1:0.5) Mix evenly, put the evenly mixed material in the reaction furnace, roast at 500°C for 0.5h, and cool the roasted material to 60°C Next, the obtained calcined sand is leached at 80°C for 30 minutes with dilute sulfuric acid (acid-mine ratio: 0.55) with a concentration of 40 g / L, and the pH of the mixed solution is adjusted to 3 with ammonia water, filtered, and the filter residue is washed with a small amount of water to calculate manganese The leaching rate is 96.3%. The leach slag adopts magnetic separation to recover iron, and the finally obtained slag can be used as raw material for cement production. The obtained filtrate is precipitated with MnS and the cobalt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com