Beneficiation method for copper nickel sulfide ore

A beneficiation method and technology for copper-nickel ore, applied in flotation, solid separation and other directions, can solve the problems of difficult separation of copper-nickel, poor quality of copper-nickel concentrate, mutual inclusion of copper and nickel, etc. The effect of wide application and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

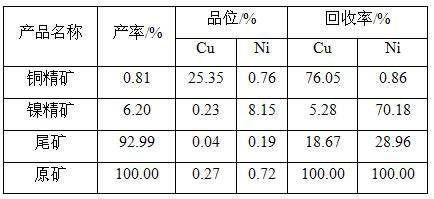

[0038] The selected raw ore is a polymetallic copper-nickel sulfide ore containing chalcopyrite, pentlandite, pyrrhotite, magnetite, pyrite, and limonite. The gangue minerals in the ore include talc, translucent Stone, pyroxene, olivine, etc., the copper and nickel grades in the ore are low, of which Cu: 0.27%, Ni: 0.72%. The intercalation characteristics of copper and nickel minerals are complex, the intercalation particle size is mainly medium-grained, and the intercalation is medium-fine, the monomer dissociation is poor, and the copper and nickel are closely connected.

[0039] The complex and low-grade fine-grained copper-nickel sulfide ore is flotation-separated by using the copper-nickel sequential priority flotation separation process of the present invention, and the separation steps are as follows:

[0040] (1) Grinding the raw ore, the grinding fineness is -0.074mm and greater than 78%.

[0041] (2) Preferential flotation of copper minerals is carried out on the gr...

Embodiment 2

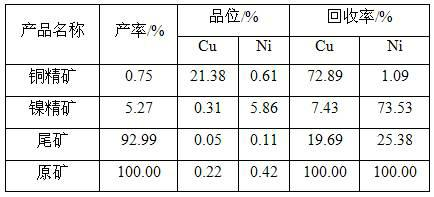

[0052] The selected raw ore is a polymetallic copper-nickel sulfide ore containing chalcopyrite, pentlandite, pyrrhotite, magnetite, pyrite and limonite. The gangue minerals in the ore include olivine and talc , tremolite, pyroxene, etc., the copper and nickel grades in the ore are low, of which Cu: 0.22%, Ni: 0.42%. The intercalation characteristics of copper and nickel minerals are relatively complex, the intercalation particle size is mainly medium-grained, and the intercalation is medium-fine, the monomer dissociation is poor, and the copper and nickel are closely connected.

[0053] The complex and low-grade fine-grained copper-nickel sulfide ore is flotation-separated by adopting the copper-nickel sequential priority flotation separation process of the present invention, and the separation steps are as follows:

[0054] (1) Grinding the raw ore, the grinding fineness is -0.074mm and greater than 82%.

[0055] (2) Preferential flotation of copper minerals is carried out ...

Embodiment 3

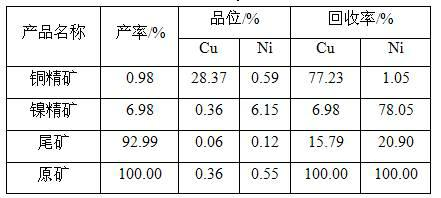

[0066] The selected raw ore is a polymetallic copper-nickel sulfide ore containing chalcopyrite, copper blue, pentlandite, pyrite, magnetite, pyrrhotite, etc. The gangue minerals in the ore mainly include olivine, snake Taurite, soapstone, talc, chlorite, etc., the grades of copper and nickel minerals in the raw ore are low, of which Cu: 0.36%, Ni: 0.55%. The intercalation characteristics of copper and nickel minerals are more complex, the intercalation particle size is mainly medium-grained, coarse-medium-grained, and some are micro-fine-grained, and the monomer dissociation is better.

[0067] The copper-nickel sulfide ore is carried out by flotation separation by adopting the copper-nickel sulfide ore in sequence by the priority flotation separation process of the present invention, and the separation steps are as follows:

[0068] (1) Grind the raw ore, and the grinding fineness is -0.074mm greater than 75%.

[0069] (2) Preferential flotation of copper minerals is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com