Process and special equipment for plating copper on special steel piece with deep/blind hole

A special-shaped steel and copper plating technology, applied in electrolytic components, electrolytic processes, etc., can solve the problems of narrow current density range, cumbersome purchase, transportation, storage, and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

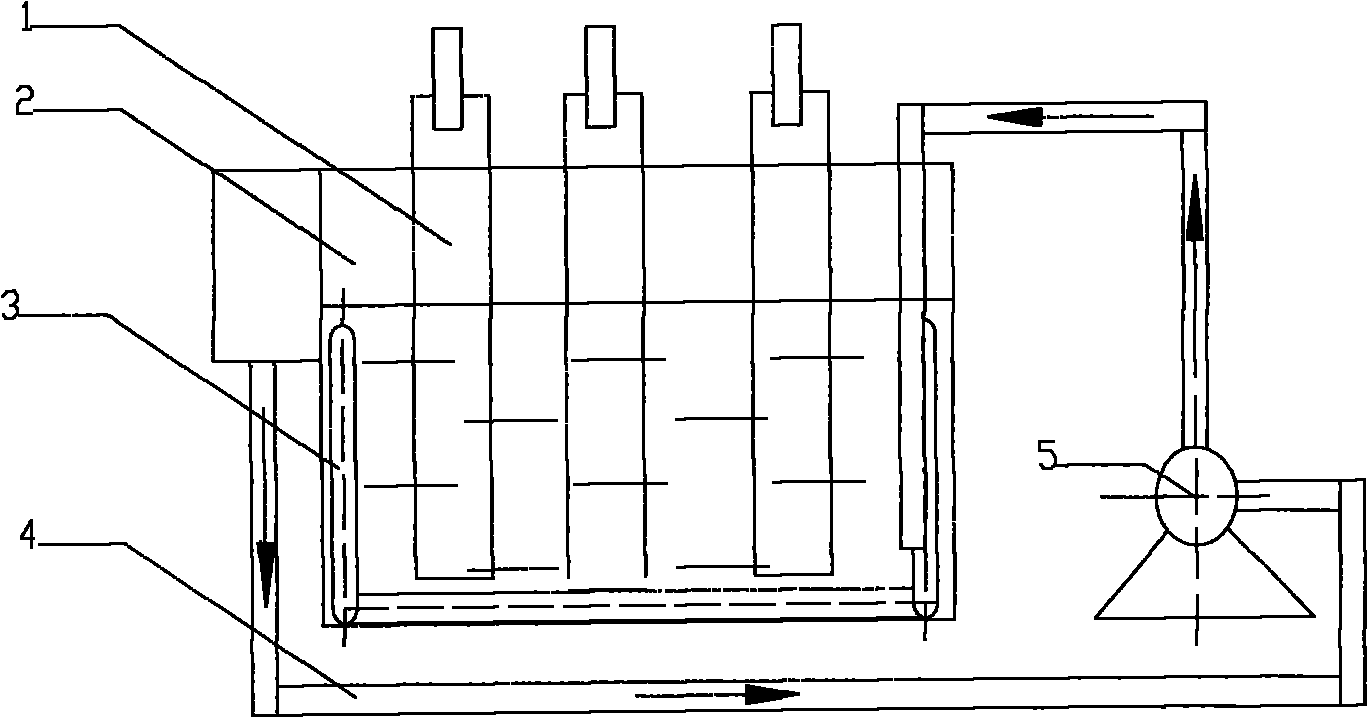

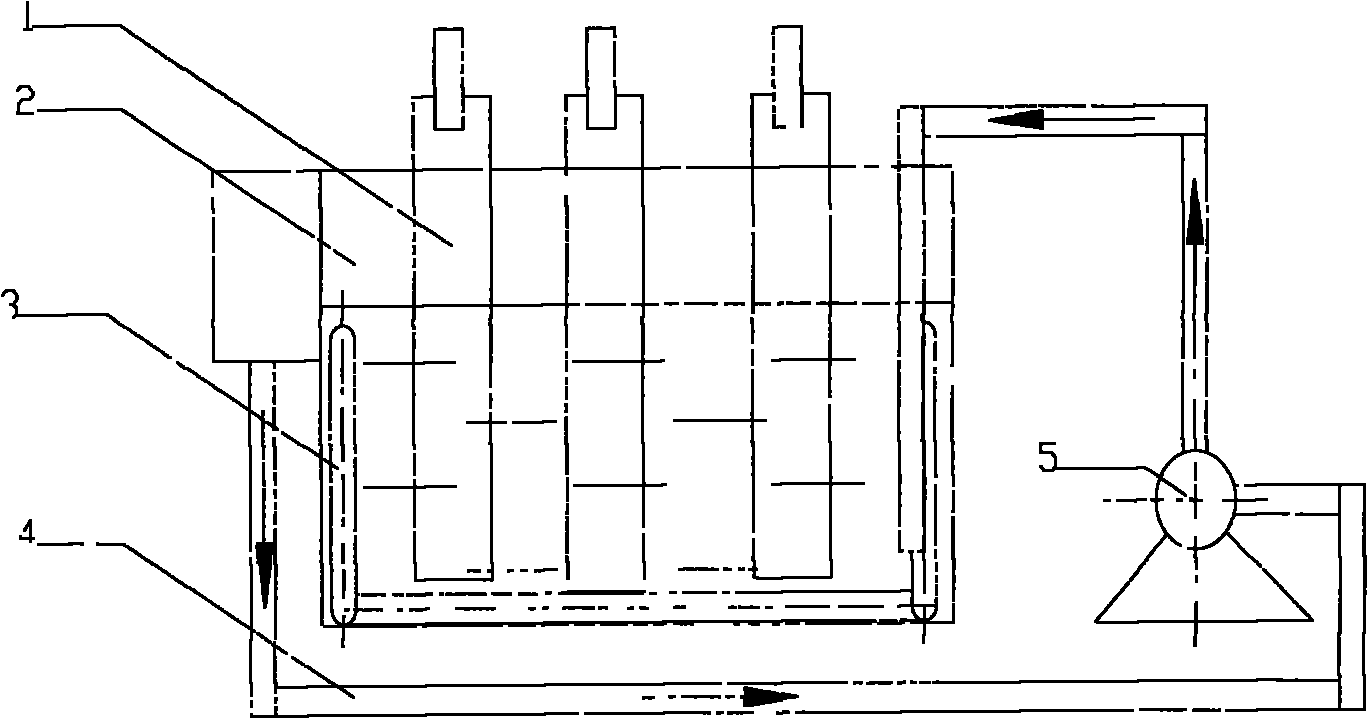

Image

Examples

Embodiment 1

[0115] Embodiment 1: A kind of process of copper plating on special-shaped steel parts with deep / blind holes-undercoating copper plating, its process is as follows:

[0116] Chemical degreasing, hot water washing, electrolytic degreasing, hot water washing, cold water washing, pickling, secondary cold water washing, neutralization, cold water washing, cyanide-free copper plating, secondary cold water washing, tin plating, secondary cold water washing, medium And, hot water washing, passivation, secondary hot water washing, hot pure water washing, alcohol dehydration, shaking off residual water, drying, inspection;

[0117] The chemical degreasing process uses a working tank made of 1Cr18Ni9Ti material, with a built-in serpentine steam heating tube. The chemical degreasing process solution composition and process parameters:

[0118] High-efficiency cleaning agent RLQ-110: 40-70% (mass percentage concentration),

[0119] Total alkalinity: 50-65 points,

[0120] Temperature: 5...

Embodiment 2

[0180] Embodiment two: a kind of technology-anti-carburizing copper plating on the special-shaped steel piece with deep / blind hole, its operation is as follows:

[0181] Chemical degreasing, electrolytic degreasing, hot water washing, cold water washing, pickling, cold water washing, neutralization, cold water washing, cyanide-free copper plating, cold water washing, compressed air drying, inspection;

[0182] The chemical degreasing process uses a working tank made of 1Cr18Ni9Ti material, with a built-in serpentine steam heating tube, the chemical degreasing process solution composition and process parameters:

[0183] High-efficiency cleaning agent RLQ-110: 40-70% (mass percentage concentration),

[0184] Total alkalinity: 50-65 points,

[0185] Temperature: 50~80℃,

[0186] Time: 5-10 minutes.

[0187] The working tank used for the electrolytic degreasing is a stainless steel tank made of 1Cr18Ni9Ti material, with a built-in stainless steel anode plate, a serpentine stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com