Preparation method and thixotropy test method of nano calcium carbonate with negative thixotropy

A nano-calcium carbonate, negative thixotropic technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of less research on calcium carbonate, and achieve considerable economic benefits and dispersion performance. Excellent, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The preparation method of the present invention is used to prepare a nano-calcium carbonate product with negative thixotropic properties, so that it can be used in the polymer industry to increase its dispersion and help extrusion molding in the polymer industry. Generally, it includes the following steps:

[0027] (1) The optimized natural limestone is calcined at 800°C-1000°C for 6-8 hours to become calcium oxide, then digested with water, passed through a 200-mesh sieve to remove coarse particles, and refined into calcium hydroxide emulsion;

[0028] (2) Adjust the concentration of calcium hydroxide emulsion to 8% to 12% and the temperature to 18°C to 25°C, then send it to the bubbling carbonization tower, and pass in a certain concentration of 25% to 40% of carbon dioxide for bubbling carbonization, carbonization When the pH value is less than 7, it is the end point of carbonization, and the calcium carbonate cooked pulp with a dry powder specific surface area of ...

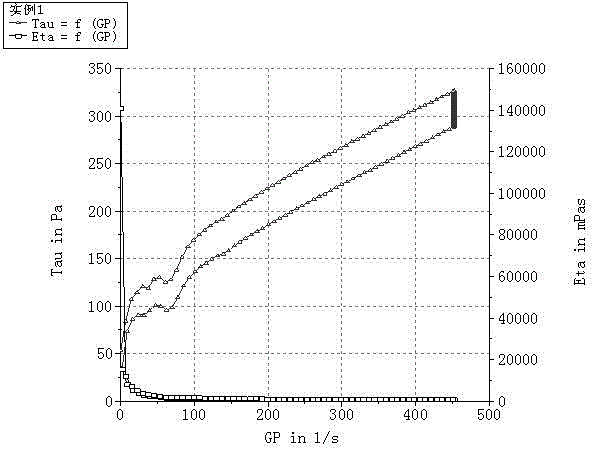

example 1

[0034] Limestone is calcined at 900°C for 8 hours. After the calcination is completed, it is slightly cooled and placed in clean water for digestion reaction. After digestion, it is passed through 200 sieves to obtain refined milk of lime, and then water is added to adjust the solubility of milk of lime to 10%. After the temperature is 20°C, it is sent to the bubbling carbonization tower, and carbon dioxide gas with a concentration of 30% is introduced for carbonization, and the carbonization is carried out until the pH value is less than 7, and the carbonization is terminated. The specific surface area of the dry powder is measured to be 36.4m2 / g; The slurry was precipitated, and the supernatant water was removed, and concentrated to a concentration of 20%. Send this cooked pulp into the activation reaction tank, add the configured stearic acid saponification solution (wherein the consumption of stearic acid is 5% of dry basis calcium carbonate quality, the preparation of it...

example 2

[0036] The operation method of example 2 is identical with example 1, and difference is that the specific surface area of the dry powder calcium carbonate that carbonization obtains is 34.6 m / g, and the consumption of the 12-hydroxy stearic acid that adds is 1.5% of dry basis nanometer calcium carbonate quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com