Mercury removal process based on lime-gypsum method desulphurization system and mercury removal absorption liquid

A desulfurization system and mercury absorption technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of mercury reduction not being effectively suppressed, increased absorption liquid corrosion, and failure to achieve stabilization, etc. High removal rate, suppression of mercury reduction, and high mercury removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

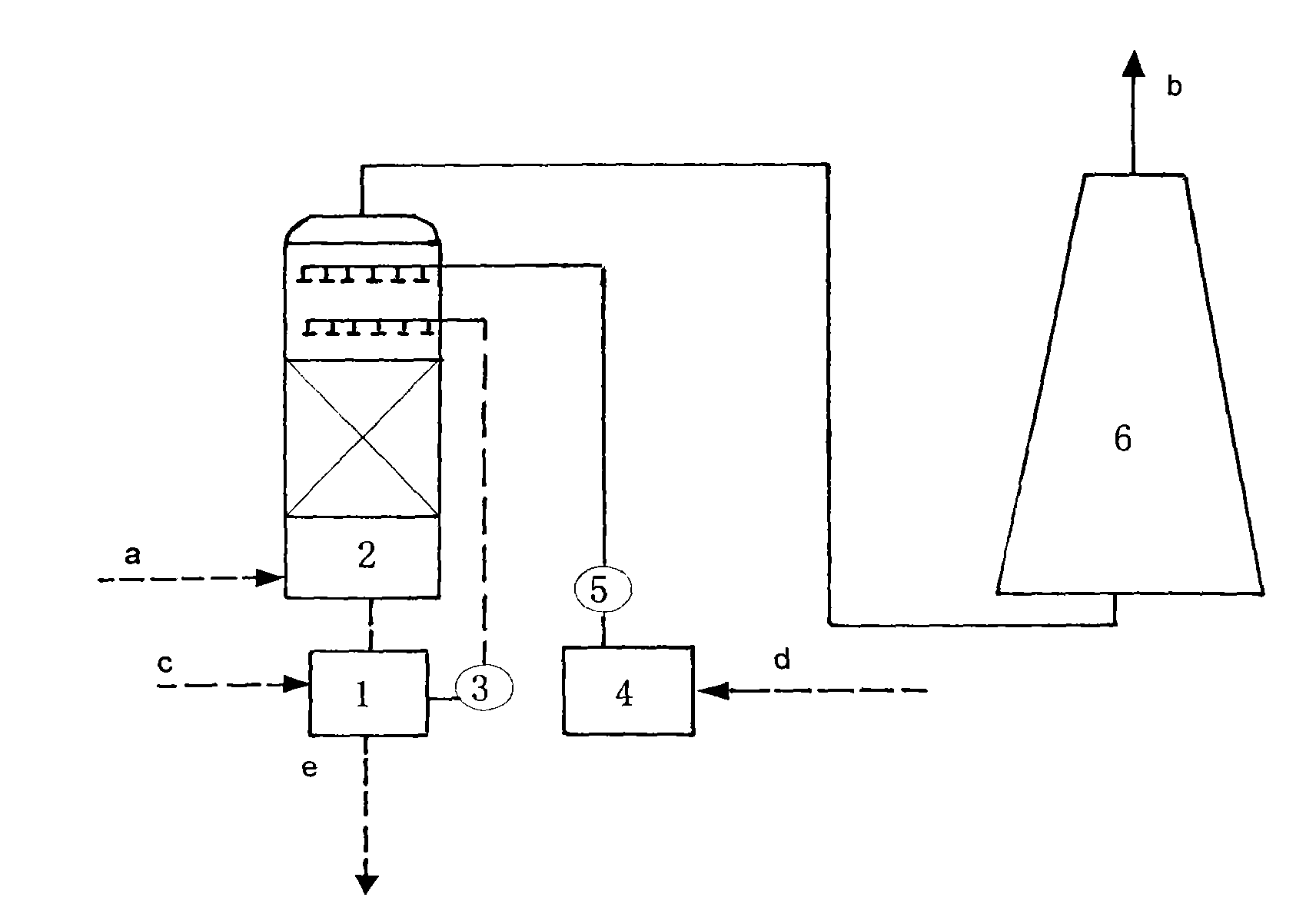

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Ammonium persulfate oxidation combined with calcium hydroxide absorption to remove mercury

[0047] The flue gas mercury removal absorption liquid used in this embodiment includes calcium hydroxide slurry with a mass concentration of 2%. Ammonium persulfate is added to the calcium hydroxide slurry in an amount of 5 mmol / L. Under simulated flue gas conditions , the mercury inlet concentration is 80μg / L, the sulfur dioxide concentration is 1500ppm, and the nitrogen oxide concentration is 300ppm. Through single-layer spraying, the removal efficiency of sulfur dioxide is above 60%, the removal efficiency of nitrogen oxide is above 20%, and the removal efficiency of mercury reaches 50%.

Embodiment 2

[0048] Example 2: Ammonium persulfate oxidation combined with calcium sulfite absorption to remove mercury

[0049] The flue gas mercury removal absorption liquid used in this embodiment includes calcium sulfite slurry with a mass concentration of 5%. Ammonium persulfate is added to the calcium sulfite slurry in an amount of 8mmol / L. Under simulated flue gas conditions , the mercury inlet concentration is 80μg / L, the sulfur dioxide concentration is 1500ppm, and the nitrogen oxide concentration is 300ppm. Through single-layer spraying, the removal efficiency of sulfur dioxide is above 60%, the removal efficiency of nitrogen oxide is above 20%, and the removal efficiency of mercury reaches 53%.

Embodiment 3

[0050] Example 3: Sodium persulfate and ammonium sulfate oxidation combined with calcium hydroxide absorption to remove mercury

[0051] The flue gas mercury removal absorbing liquid used in this embodiment comprises calcium hydroxide slurry with a mass concentration of 2%, sodium persulfate and ammonium sulfate are added to the calcium hydroxide slurry, and its addition is sodium persulfate 5mmol / L, Ammonium sulfate is 8mmol / L. Under simulated flue gas conditions, the mercury inlet concentration is 80μg / L, the sulfur dioxide concentration is 1500ppm, and the nitrogen oxide concentration is 300ppm. The oxide removal efficiency is above 30%, and the mercury removal efficiency reaches 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com