Process of preparing dipentaerythritol and/or tripentaerythritol

A technology of dipentaerythritol and tripentaerythritol, which is applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve the problems of inability to meet quality and quantity requirements, difficulty of dipentaerythritol, high energy consumption, etc., and achieve simple separation Ease of operation, high product purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

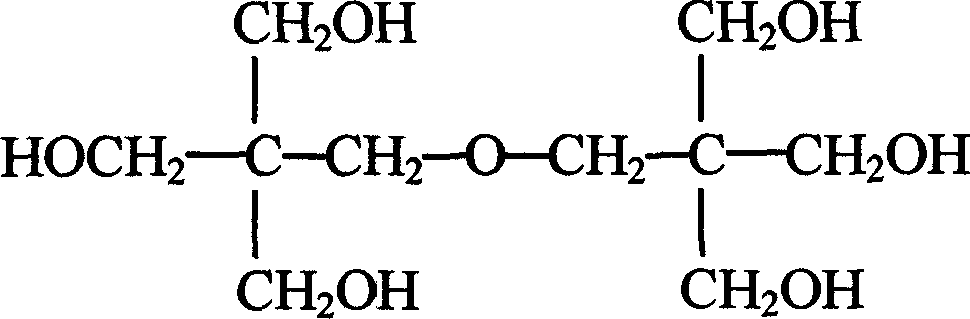

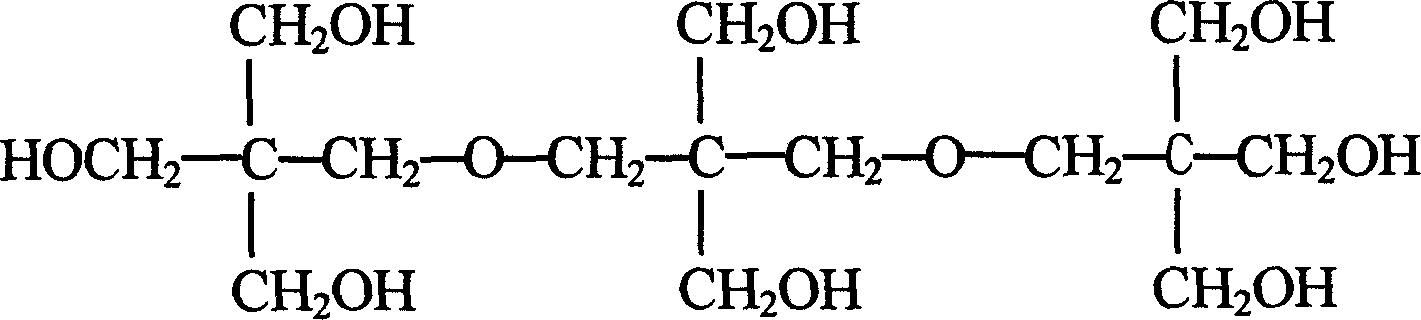

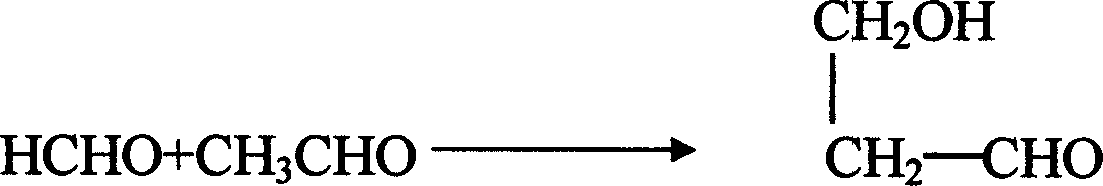

[0039] Step 1: Take 10 mol of formaldehyde with a concentration (mass concentration) of 18%, 1 mol of acetaldehyde with a concentration of 50%, and 1.2 mol of a calcium hydroxide solution with a concentration of 5% and add them to an atmospheric chemical reaction kettle with a stirrer Stirring is carried out, the temperature is controlled at 15°C, and the reaction time is controlled at 4 hours. Firstly, pentaerythritol (Pentae) is generated through condensation and Toulon reaction, and the main component of pentaerythritol (Pentae) is di-pentaerythritol (Di-Pentae) through etherification and disproportionation reactions. And the condensation liquid of tripentaerythritol (Tri-Pentae), generate simultaneously by-product and impurity mainly be the acetals of pentaerythritol (Pentae), calcium formate, methyl alcohol.

[0040] Step 2: Rectification adopts double towers to remove methanol, formaldehyde and part of water. The dealcoholization tower uses a packed tower equivalent to 1...

Embodiment 2

[0047] Step 1: get concentration (mass concentration) to be 2.5mol of formaldehyde of 25%, get the concentration of acetaldehyde 1mol of 90%, get concentration of calcium hydroxide (Ca(OH) 2 ) solution 1.2mol, formaldehyde and acetaldehyde as the bottom water, the calcium hydroxide solution is added in batches into a reactor with a pressure of 0.1mpa for stirring, the temperature is controlled at 40 ° C, and the reaction time is controlled at In 90 minutes, at first, pentaerythritol (Pentae) was generated through condensation and Toulon reaction, and pentaerythritol (Pentae) was generated through etherification and disproportionation reactions into condensation liquids whose main components were dipentaerythritol (Di-Pentae) and tripentaerythritol (Tri-Pentae). The by-products and impurities are mainly pentaerythritol (Pentae) acetals, calcium formate, and methanol.

[0048] Step 2: Rectification: Use double towers to remove methanol, formaldehyde and part of water: use a pack...

Embodiment 3

[0055] Get concentration (mass concentration) to be 37% formaldehyde 6.5mol, get concentration to be 99% acetaldehyde 1.2mol, get concentration to be 40% calcium hydroxide solution 1.2mol, formaldehyde and acetaldehyde make bottom water, calcium hydroxide The feeding method of adding the solution in batches is added to a 0.1mpa pressure reactor with a stirrer for stirring, the temperature is controlled at 70°C, and the reaction time is controlled at 30 minutes. First, pentaerythritol (Pentae) is generated through condensation and Toulon reaction. Pentaerythritol (Pentae) undergoes etherification and disproportionation reactions to generate a condensation liquid whose main components are dipentaerythritol (Di-Pentae) and tripentaerythritol (Tri-Pentae). Calcium, Methanol.

[0056] Step 2: Rectification: Use double towers to remove methanol, formaldehyde and part of water. The dealcoholization tower uses a packed tower equivalent to 10 trays, and the temperature is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com