Method for producing nano silicon dioxide and nano calcium carbonate by using rice hull ash and flue gas of biomass power plant

A nano-silica, nano-calcium carbonate technology, applied in the direction of silica, nanotechnology for materials and surface science, silicon oxide, etc., can solve the problem that it is difficult to achieve nano-silica, low dissolution rate of silica , industrialization difficulties and other problems, to achieve the effect of reducing waste, saving equipment investment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

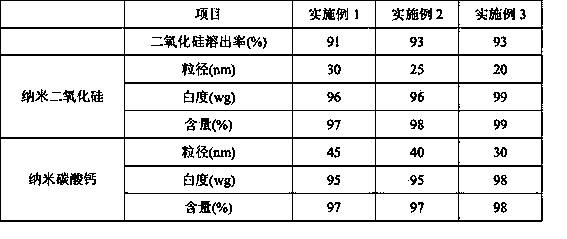

Examples

Embodiment 1

[0021] (1) Take the rice husk ash (SiO 2 Content 90wt%, BET specific surface area 60m 2 / g, SiO 2 Crystal structure: amorphous) 74kg, adding concentration is 15wt% in the sodium hydroxide solution, wherein: the mass ratio of rice husk ash: sodium hydroxide in the sodium hydroxide solution is 2.8:1, under stirring condition, heat up to 96 0 C, heat preservation reaction for 3.5 hours, filter;

[0022] (2) Put the filtrate of step (1) in the reaction kettle, add water to dilute, control the mass percentage concentration of sodium silicate in the solution to be 15% in terms of silicon dioxide, and then raise the temperature to 70 0 C, add dispersant PEG2000 (polyethylene glycol 2000), add-on is 1kg, under normal pressure condition, continuously pass into the flue gas of biomass power plant, the volume content of carbon dioxide in the flue gas is 12-20% ( v / v), the access rate is 300m 3 / h, heat preservation reaction for 2.5 hours, stop passing the flue gas, stir and mature fo...

Embodiment 2

[0026] (1) Take the rice husk ash (SiO 2 Effective content 80wt%, BET specific surface area 100m 2 / g, SiO 2 Crystal structure: amorphous) 74kg, adding concentration is 12wt% in the sodium hydroxide solution, wherein: rice husk ash: the mass ratio of sodium hydroxide in the sodium hydroxide solution is 2.6:1, under stirring condition, heat up to 97 0 C, heat preservation reaction for 3.0 hours, filter;

[0027] (2) Put the filtrate of step (1) in the reaction kettle, add water to dilute, control the concentration of sodium silicate in the solution to 10% by mass percentage in terms of silicon dioxide, and raise the temperature to 65 0 C, add dispersant PEG3000, the addition amount is 1kg, and then under normal pressure conditions, continue to pass into the flue gas of the biomass power plant, the flow rate is 500m 3 / h, the volume content of carbon dioxide in the flue gas is 12-20% (v / v), heat preservation reaction for 2.0 hours, stop the flow of flue gas, stir and mature f...

Embodiment 3

[0032] (1) Take the rice husk ash (SiO 2 Effective content 90wt%, BET specific surface area 100m 2 / g, SiO 2 Crystal structure: amorphous), adding the concentration of 10wt% sodium hydroxide solution, under stirring conditions, heating up to 98 0C, keep warm and fully react for 3.0 hours, filter;

[0033] (2) Place the filtrate of step (1) in a reaction kettle, add water to dilute, control the concentration of sodium silicate in the solution to 8% by mass in terms of silicon dioxide, and raise the temperature to 60 0 C, adding dispersant PEG3000, the amount of dispersant added is 0.5wt% of sodium silicate in the filtrate obtained in step (1) based on the mass of silicon dioxide, and then under normal pressure conditions, continue to feed the raw material after purification treatment Flue gas from a material power plant with an inflow rate of 250m 3 / h, the volume content of carbon dioxide in the flue gas is 12-20% (v / v), keep warm for 3.5 hours, stop passing the flue gas, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com