Method for preparing sodium hydrosulfide

A technology of sodium hydrosulfide and calcium hydrosulfide, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of reducing the yield of caustic soda, affecting the use of users, blocking equipment and pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

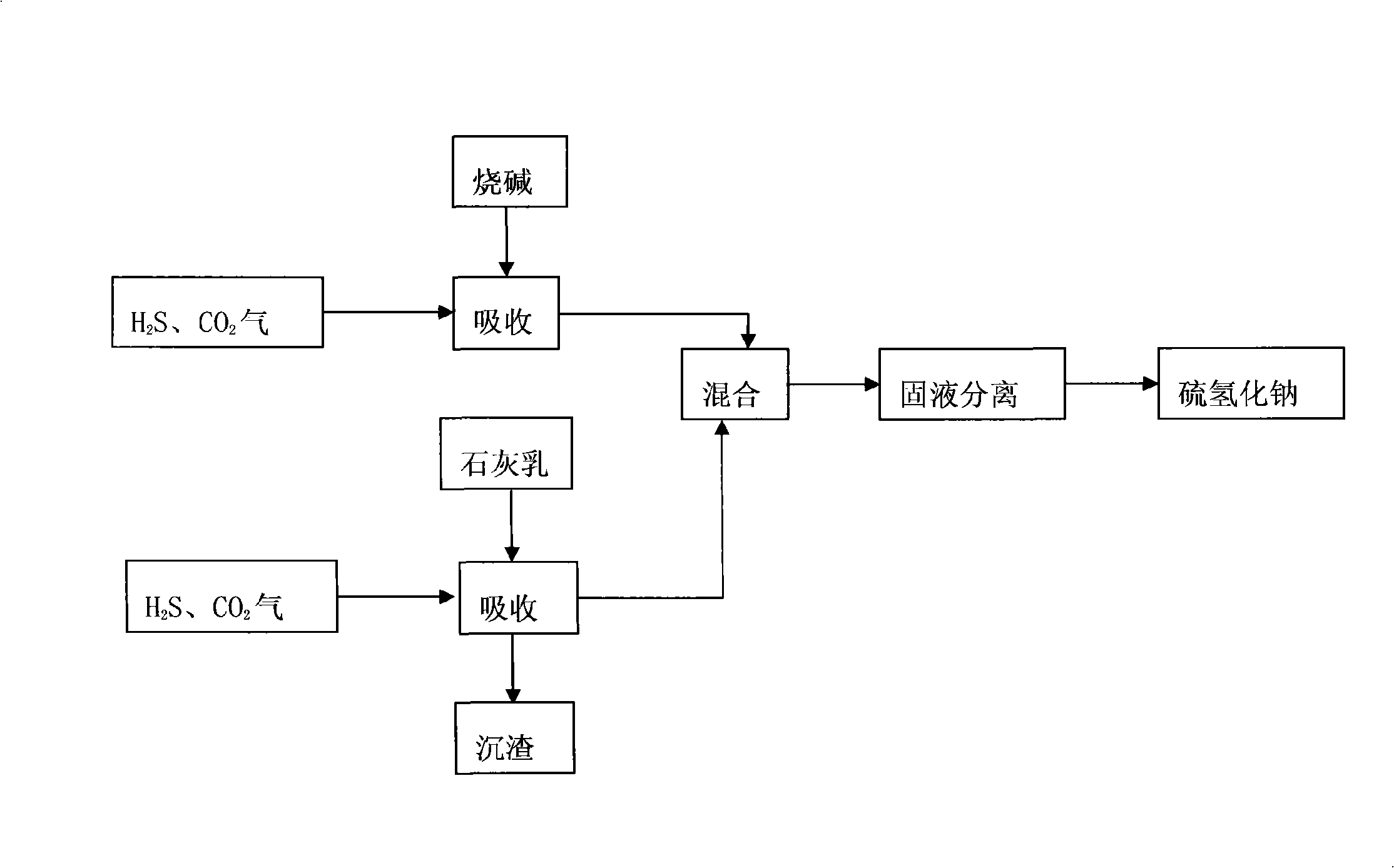

[0019] The present invention prepares the method for sodium hydrosulfide, its specific production process:

[0020] In the milk of lime with a concentration of about 12%, the hydrogen sulfide H 2 S and carbon dioxide CO 2 The mixed gas, in which the hydrogen sulfide content is more than 10%, the carbon dioxide content is not more than 90%, the temperature is controlled at 50-80°C, the pressure is -0.05--0.01Mpa, the reaction is terminated when CaS≤0.5%, and the sediment CaCO is separated 3 Obtain calcium hydrosulfide solution;

[0021] In a caustic soda solution with a concentration greater than 30%, pass it under stirring containing hydrogen sulfide H 2 S and carbon dioxide CO 2 The mixed gas, in which the content of hydrogen sulfide is more than 10%, the content of carbon dioxide is not more than 90%, the temperature is controlled at 50~80℃, the pressure is -0.05~-0.01Mpa, in Na 2 When S≤0.5%, the reaction is finished to obtain a sodium bisulfide solution containing carb...

Embodiment approach 2

[0023] When the customer does not require calcium ions in the product, the method for preparing sodium hydrosulfide in the present invention, its specific production process:

[0024] Mix lime milk with a concentration of about 12% into a caustic soda solution with a concentration greater than 30%, and pass it in with hydrogen sulfide H 2 S and carbon dioxide CO 2 The mixed gas, in which the content of hydrogen sulfide is more than 10%, the content of carbon dioxide is not more than 90%, the temperature is controlled at 50~80℃, the pressure is -0.05~-0.01Mpa, in Na 2 When S≤0.5%, the reaction ends and the sediment CaCO is separated 3 A sodium hydrosulfide product containing calcium ions is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com