Method for treating high-fluorine sewage water

A treatment method and sewage technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as large consumption, high viscosity, excessive fluorine content in wastewater, etc., to achieve Low treatment cost and effect of reducing fluoride ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

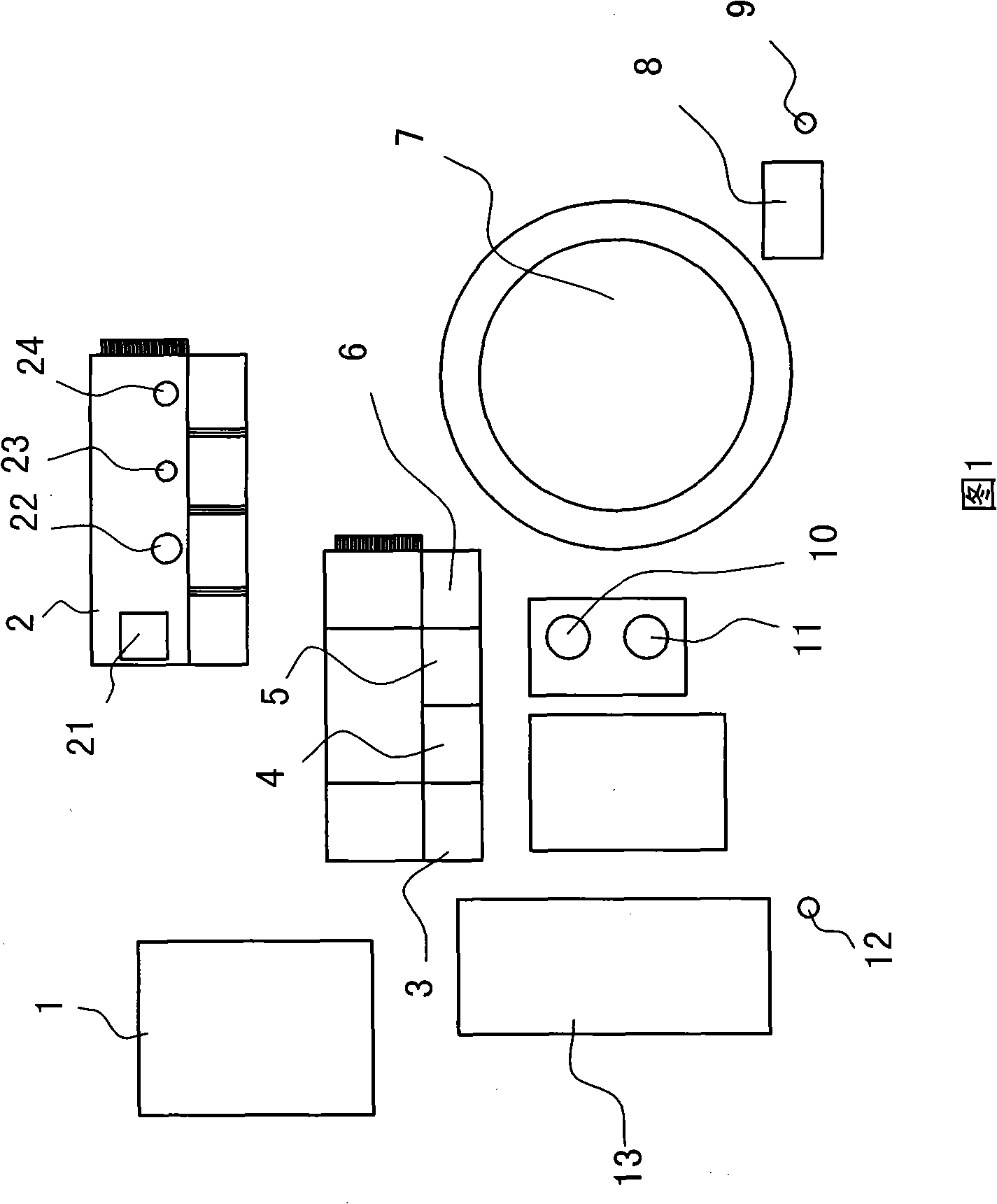

[0027] The fluorine-containing wastewater from the workshop is collected to the sewage regulating tank 13, and its F- concentration is detected to be 1200mg / l. The sewage is poured into the calcium hydroxide through the wastewater lifting pump and the amount of the 1# reaction tank (with a stirring device inside) is 40m 3 / h, the fluorine content in wastewater is 1.2kg / m 3 ×40m 3 / h=48kg / h; the content of Ca to be added is 48kg×3≈150kg, converted to Ca(OH) 2 It is 280kg, and it is configured as 5% lime emulsion in the lime milk preparation area, which is 5600kg emulsion, which is pumped to the lime milk dosing device (that is, the lime solution storage tank, with a stirring device inside), and flows to 1# reaction by flow meter The pool will react with fluorine-containing sewage to form calcium fluoride precipitates. Its pH value was detected to be 10.2, and it overflowed to the 2# reaction pool (with a stirring device inside). The dosage of calcium chloride is 280kg×40%=11...

Embodiment 2

[0030] The fluorine-containing wastewater from the workshop is collected to the sewage adjustment tank, and its F -The concentration is 800mg / l, and the amount of sewage poured into the calcium hydroxide neutralization reaction tank 1 (with a stirring device inside) through the wastewater lifting pump is 30m 3 / h, the fluorine content in wastewater is 0.8kg / m 3 ×30m 3 / h=24kg / h; the content of Ca to be added is about 24kg×3≈75kg, converted to Ca(OH) 2 It is 140kg, and it is configured as 5% lime emulsion in the lime milk preparation area, which is 2800kg emulsion. It is pumped to the lime milk dosing device (that is, the lime milk storage tank, with a stirring device inside), and flows to the reaction tank through the flow meter. The fluoride-containing sewage undergoes a neutralization reaction to form calcium fluoride precipitates. Detect that its pH value is 10.5, and overflow to the calcium chloride reaction tank 2 (stirring device is arranged in it). The dosage of cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com