Combined treatment method for heavy metal sludge and waste acid

A technology for heavy metal sludge and disposal methods, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of carcinogenicity, occupation of land resources, secondary pollution, etc. Simple operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

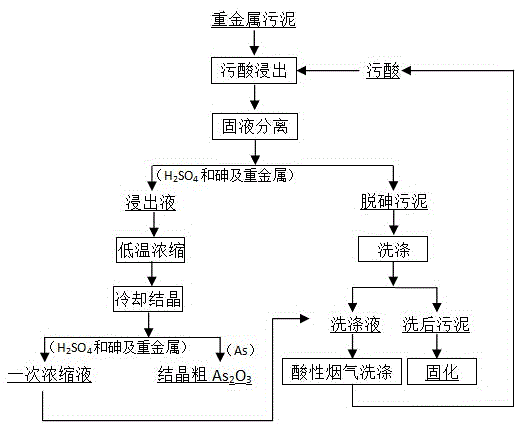

[0020] like figure 1 As shown, the joint disposal method of heavy metal sludge and sewage acid, its specific steps are as follows:

[0021] (1) Firstly, the heavy metal sludge is naturally air-dried, and then crushed to a particle size of 1mm;

[0022] (2) Add dirty acid to the heavy metal sludge crushed in step (1) (the heavy metal sludge comes from the lime iron salt method, and its composition is shown in Table 1) according to the liquid-solid ratio of 2:1ml / g (the dirty acid comes from the colored Sulfuric acid containing a large amount of arsenic and other impurities produced by the sulfuric acid workshop of the smelter after washing the smelting flue gas, the main components are shown in Table 2), stirred at room temperature for 5 hours to make the mixture of the two milky, and after solid-liquid separation Obtain leachate and dearsenic sludge;

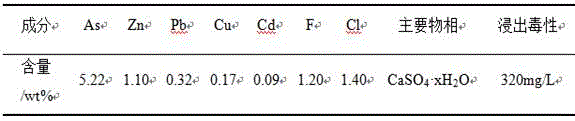

[0023] Table 1

[0024]

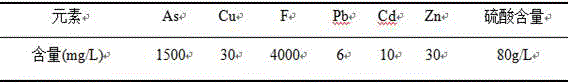

[0025] Table 2

[0026]

[0027] (3) Concentrate the leaching solution obtained in step (2...

Embodiment 2

[0031] like figure 1 As shown, the joint disposal method of heavy metal sludge and sewage acid, its specific steps are as follows:

[0032] (1) Firstly, the heavy metal sludge is naturally air-dried, and then crushed to a particle size of 10mm;

[0033] (2) Add dirty acid to the heavy metal sludge crushed in step (1) (the heavy metal sludge comes from the lime iron salt method, and its composition is shown in Table 3) according to the liquid-solid ratio of 20:1ml / g (the dirty acid comes from the colored Sulfuric acid containing a large amount of arsenic and other impurities produced by the sulfuric acid workshop of the smelter after washing the smelting flue gas, the main components are shown in Table 4), stirred at room temperature for 15 hours to make the mixture of the two milky, and after solid-liquid separation Obtain leachate and dearsenic sludge;

[0034] table 3

[0035]

[0036] Table 4

[0037]

[0038] (3) Concentrate the leachate obtained in step (2) at l...

Embodiment 3

[0042] like figure 1 As shown, the joint disposal method of heavy metal sludge and sewage acid, its specific steps are as follows:

[0043] (1) Firstly, the heavy metal sludge is naturally air-dried, and then crushed to a particle size of 8mm;

[0044] (2) Add dirty acid to the heavy metal sludge crushed in step (1) (the heavy metal sludge comes from the lime iron salt method, and the composition is shown in Table 5) according to the liquid-solid ratio of 15:1ml / g (the dirty acid comes from the colored The flue gas produced by pyrometallurgy and calcined copper sulfide ore, zinc sulfide ore, lead sulfide ore, etc. in the smelter, the main components are shown in Table 6), stirred at room temperature for 10 hours to make the mixture of the two become milky, and the solid-liquid separation Finally, leachate and arsenic-removed sludge are obtained;

[0045] table 5

[0046]

[0047] Table 6

[0048]

[0049] (3) Concentrate the leaching solution obtained in step (2) at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com