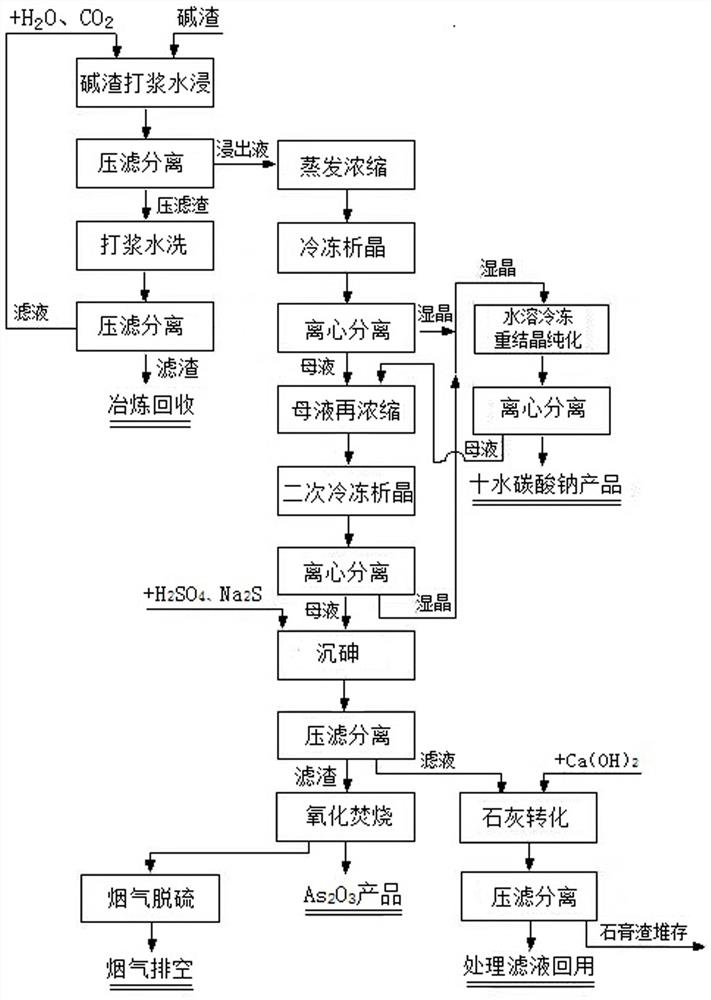

A method for recycling and processing arsenic slag resources by freezing and separating arsenic and alkali in the immersion solution of alkali slag

A freeze-separation and resource recovery technology, applied in chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, arsenic compounds, etc., can solve the problems of low alkali recovery rate, high production cost, and high residual alkali. Achieve the effect of stable technical process, low production cost and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Completed in a smelting plant in Hunan, it can process 60T of alkali slag per day. Average typical composition of alkali slag used: H 2 O: 25-32%, As: 5%, Sb: 4%, Pb: 2%, Sn: 0.8%, In: 0.08%, Na 2 CO 3 : 40%, Na 2 O: 5% (unweathered), balance SiO 2 +Fe+CaO and other ash. The specific process is as follows:

[0051] Step 1: Soda slag beating and water immersion. The specific steps are: crush the alkali slag with a block size of 10-20 mm, and mix it with circulating beating water into a ball mill installed at a low position to make a slurry. ℃ to stop heating), the slurry pump pumps part of the slurry to feed water to the hammer crusher, as the alkali slag continues to be crushed and beaten, the concentration in the stirring tank increases, and when the measured slurry specific gravity reaches 1.05-1.10, CO is passed into the tank 2 Gas, when the specific gravity of the slurry reaches 1.30-1.40 (there is a large amount of insoluble slag with a large specific gravit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com