Method, with a side blowing furnace, of treating high-arsenic ore

A technology of side-blown furnace and high-arsenic ore, which is applied in the field of metallurgy, can solve problems such as the influence of arsenic collection efficiency, ineffective recovery, and low arsenic recovery rate, and achieve the effects of strong adaptability of furnace materials, increased recovery rate, and avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

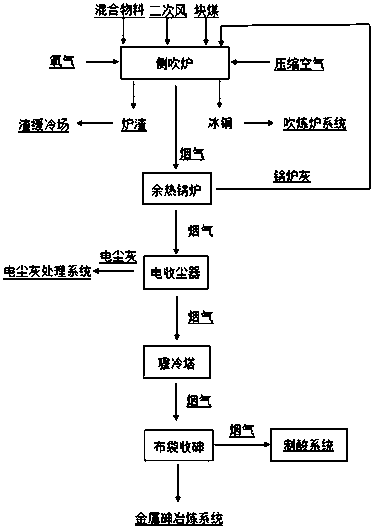

[0032] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing: a kind of method for side-blown furnace processing high arsenic ore, comprises the following steps:

[0033] A. Ingredients:

[0034] Mix gold concentrate, lead matte, high-arsenic ore, quartz stone, coal, and refined soot according to the ratio of 25:5:20:0.23:1.6:1.5, and adjust the iron-silicon ratio of the output slag to 1.3. The mixed material required by the process is added to the side blowing furnace, and the elemental analysis table of the mixed material is shown in Table 2;

[0035] Table 2

[0036]

[0037] B. Melting:

[0038] 1) The oxygen-enriched side-blowing furnace is used for smelting. At a high temperature of 1230°C, the oxygen-enriched air blown into the furnace undergoes physical reactions such as water evaporation with the mixed charge, and at the same time, high-valent sulfides are decomposed and oxidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com