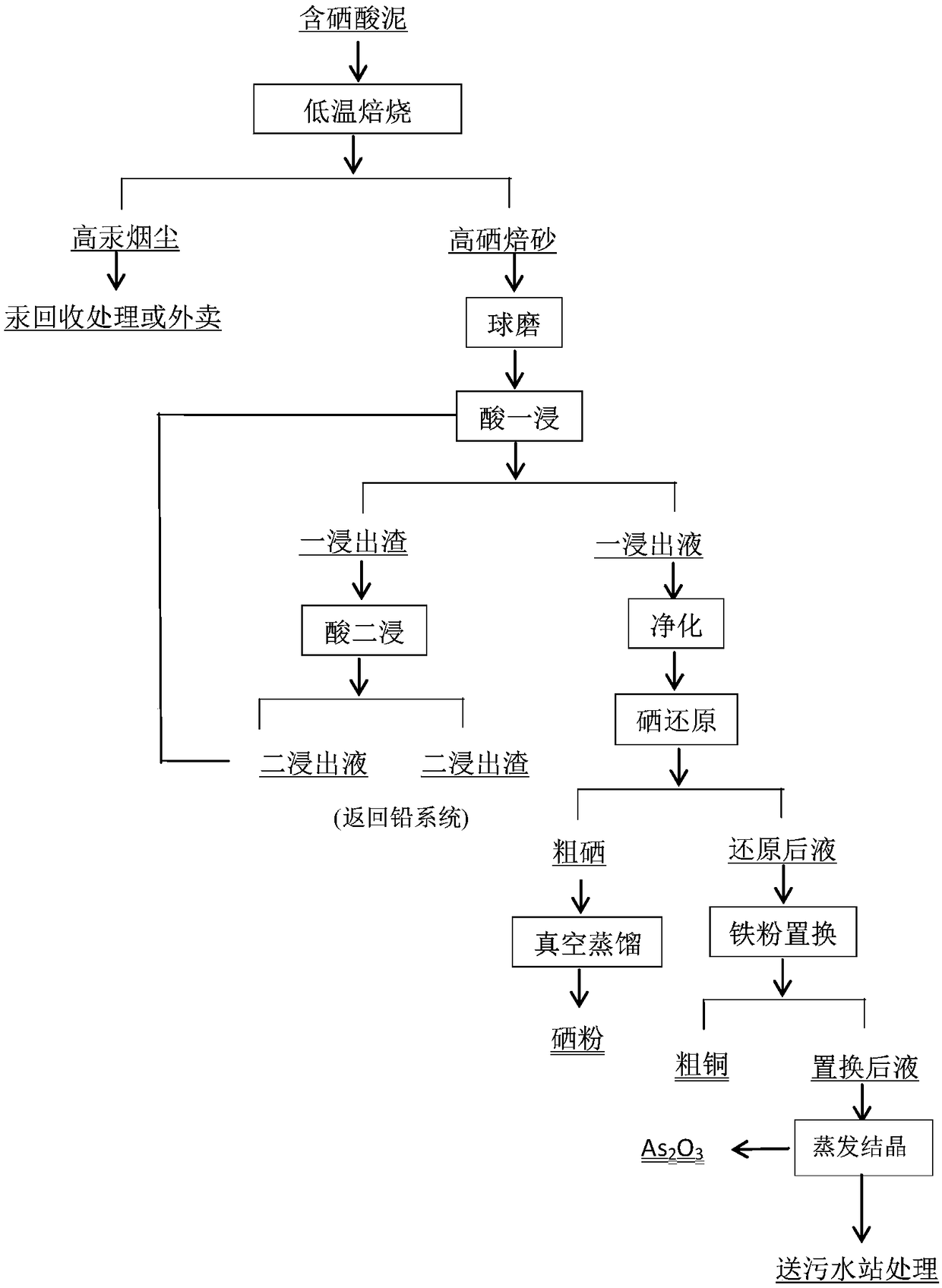

Method of recovering valuable metal from selenium-containing acid mud

A technology of valuable metals and selenate mud, which is applied in chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, element selenium/tellurium, etc., can solve the problems of difficult recovery and achieve the goal of saving leaching rate The effect of cost, short process flow and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Low-temperature roasting: Take 500g of selenium-containing mud (Pb 38%, Cu5.76%, As8.5%, Se3.6%, Hg0.55%) and roast in a crucible at a roasting temperature of 360°C for 6 hours. After roasting, The mercury removal rate is 99%, and there is almost no loss of selenium, copper and lead.

[0031] Acid leaching: Take 200g of the above-mentioned roasted sample, add sulfuric acid solution or acid secondary immersion solution, the liquid-solid ratio is 5:1, react for 2 hours at a water bath temperature of 80°C, control the acidity at the end point to 50g / L, filter and sample for testing, the liquid composition For: H + 51.27g / L, As 14.45g / L, Cu 10.05g / L, Se 4.67g / L, the solution has no mercury ions.

[0032] Acid two leaching: add sulfuric acid solution to the above-mentioned acid one leaching residue at a liquid-solid ratio (L / kg) of 5:1, control the acidity at the end point to 80g / L, react at a water bath temperature of 80°C for 2 hours, then filter, and sample the component...

Embodiment 2

[0037] Low-temperature roasting: take 500g of selenium-containing mud (Pb47%, Cu 3.76%, As 6.5%, Se 4.6%, Hg 1.77%) and roast in a crucible. The roasting temperature is 400°C, and the heat preservation is 5h. The mercury removal rate after roasting is 99%. %, almost no loss of selenium, copper and lead.

[0038] Acid leaching: Take 200g of the above-mentioned roasted sample, add sulfuric acid solution or acid second immersion solution, the liquid-solid ratio is 4:1, and react for 2 hours at a water bath temperature of 80°C, add sulfuric acid to control the end-point acidity to 60g / L, filter and sample for testing, The liquid composition is: H + 60.27g / L, As15.05g / L, Cu 7.33g / L, Se 10.08g / L, no mercury ion in solution assay.

[0039]Acid two leaching: add sulfuric acid solution to the above acid one leaching residue at a liquid-solid ratio of 4:1, then add concentrated sulfuric acid to adjust the acidity to 95g / L, react at a water bath temperature of 80°C for 2 hours and filte...

Embodiment 3

[0044] Low-temperature roasting: Take 500g of selenium-containing mud (Pb 53%, Cu 4.76%, As 7.5%, Se 5.3%, Hg3.04%) and roast in a crucible at a roasting temperature of 500°C, keep it warm for 4 hours, and remove mercury after roasting The rate is 99%, and there is almost no loss of selenium, copper and lead.

[0045] Acid leaching: Take 200g of the above-mentioned roasted sample, add sulfuric acid solution or acid second immersion solution, the liquid-solid ratio is 4:1, react for 2 hours at a water bath temperature of 80°C, add sulfuric acid to control the end-point acidity to 80g / L, filter and sample for testing, The liquid composition is: H + 79.27g / L, As16.11g / L, Cu 8.43g / L, Se 10.66g / L solutions were assayed without mercury ions.

[0046] Acid two leaching: Add sulfuric acid solution to the above-mentioned acid one leaching residue at a liquid-solid ratio of 4:1, then add concentrated sulfuric acid to adjust the acidity to 120g / L, react at a water bath temperature of 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com