Patents

Literature

99results about How to "No hazardous waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

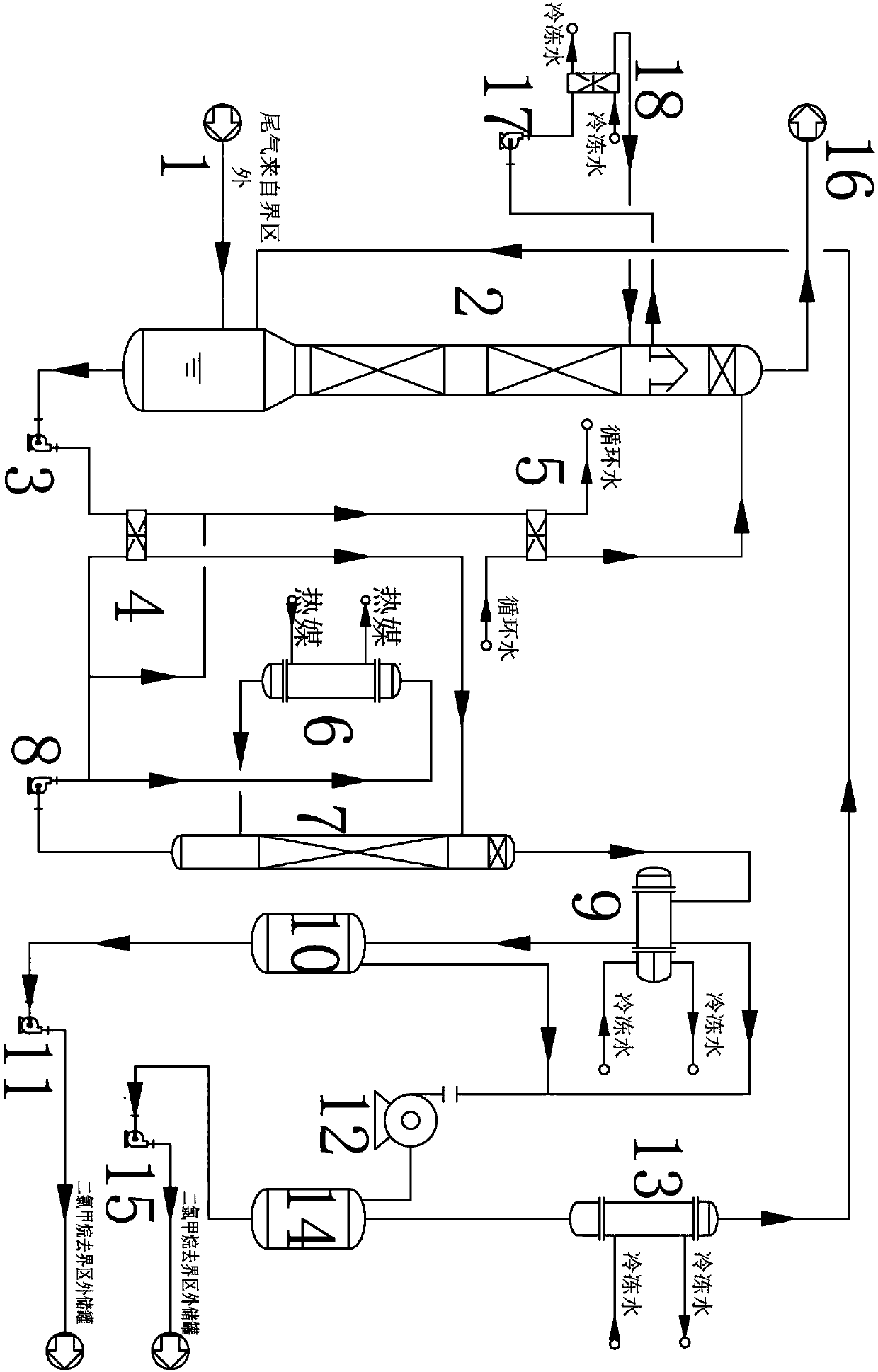

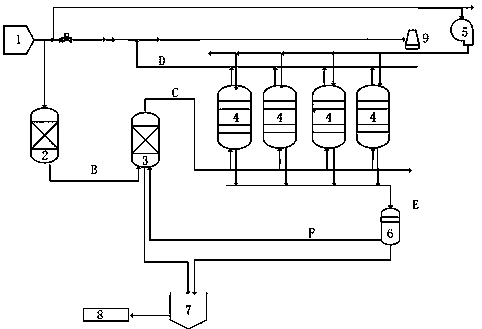

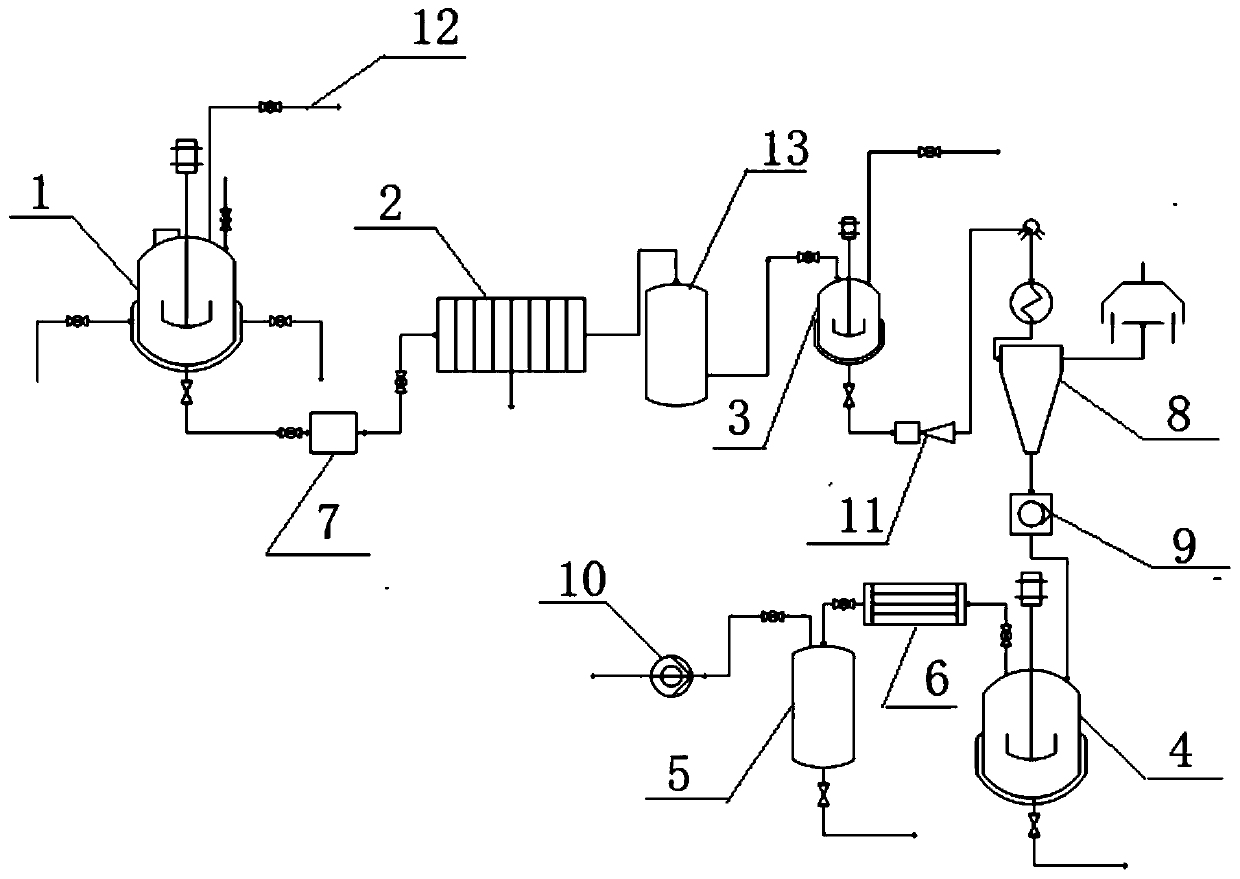

Resource recycling device and process of dichloromethane tail gas

PendingCN107803100ATake advantage ofReduce dosageGas treatmentDispersed particle separationCirculating pumpVacuum pump

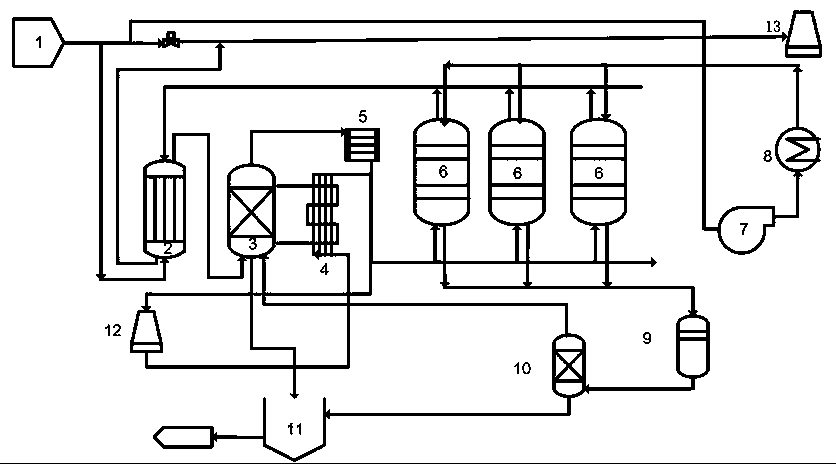

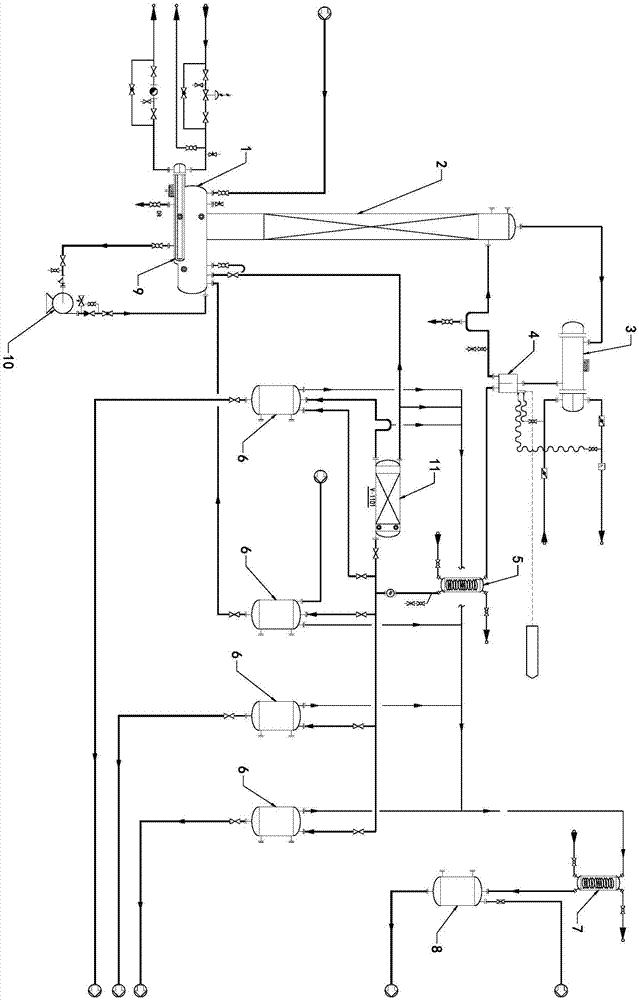

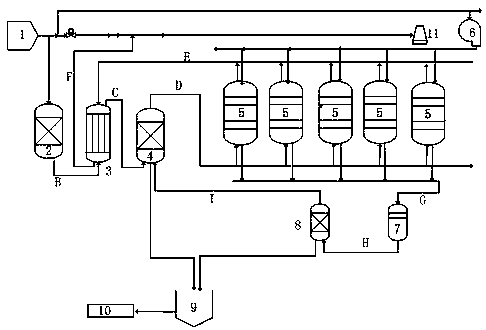

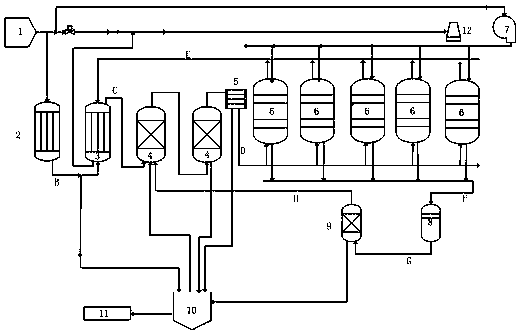

The invention discloses a resource recycling device and process of dichloromethane tail gas. According to the device, the bottom of an absorption tower is connected with an absorbent heat exchanger through an absorption tower kettle extraction pump; the absorbent heat exchanger is connected to the upper part of an desorption tower; the absorbent heat exchanger is connected with an absorbent primary cooler; the bottom of a falling film evaporator is connected with the lower part of the desorption tower; the bottom of the desorption tower is connected with the top of the falling film evaporatorthrough a falling film circulating pump; a desorption tower top condenser is connected with the top of the desorption tower; the desorption tower top condenser is connected with the top of a desorption tower top receiving tank; the top of the desorption tower top receiving tank is connected with an after-pumping receiving tank through a vacuum pump; the vacuum pump is connected with the desorptiontower top condenser; the top of the after-pumping receiving tank is connected with an after-pumping condenser; and the top of the after-pumping condenser is connected to the lower part of the absorption tower. The device provided by the invention is simple in structure, convenient in operation, and high in solvent recovery rate; dangerous waste is not generated; the environment-friendly requirement can be met; the emission is safe; and resource recycling is realized.

Owner:烟台国邦化工机械科技有限公司

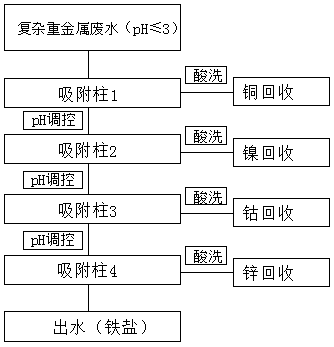

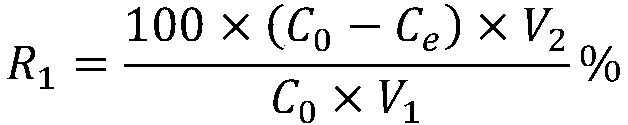

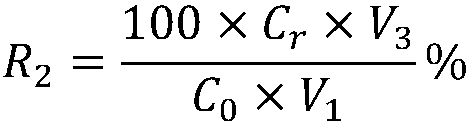

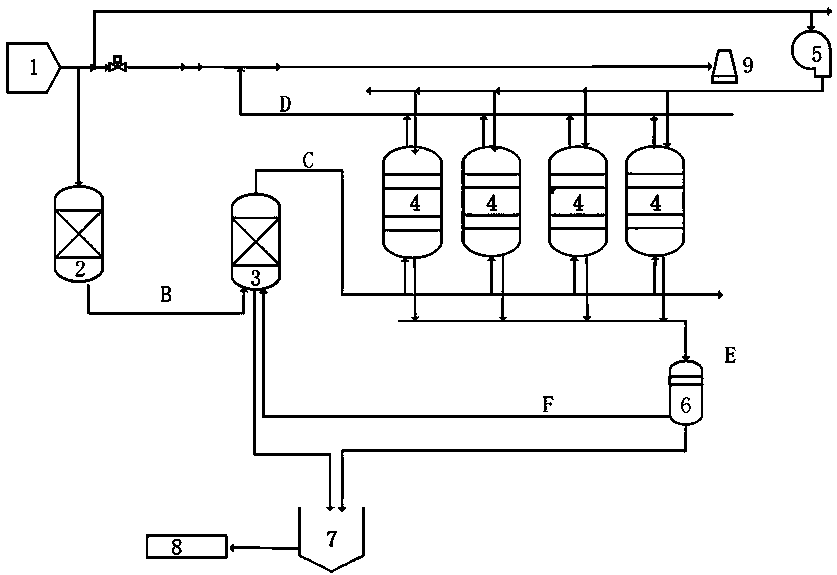

Acid-resistant chelating resin combinational adjusting and controlling method for quality-divided recycling complex heavy metal

ActiveCN107217142AWidely applicable processingBroad-spectrumWater contaminantsProcess efficiency improvementStrong acidsTreated water

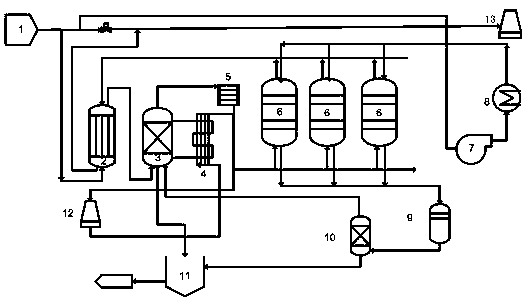

The invention discloses an acid-resistant chelating resin combinational adjusting and controlling method for quality-divided recycling complex heavy metal, and belongs to the field of heavy metal wastewater resourceful treatment. The acid-resistant chelating resin combinational adjusting and controlling method for quality-divided recycling complex heavy metal comprises the following steps that strong acid wastewater with a plurality of heavy metals are sequentially pumped into an absorbing column which is filled with different kinds of acid-resistant chelating resin, by stair-stepped adjusting and controlling of the pH value (pH is smaller than or equal to 3) of the solution, multistage selective separation of a plurality of heavy metal ions such as copper, nickel, cobalt, zinc and iron can be achieved, treated water mainly contains molysite which can be used for producing the iron-based flocculating agent or water purifying agent; high concentrated regenerating liquid is obtained by adopting diluted acid to regenerate acid-resistant chelating resin, and high purity recycling can be achieve by technologies such as neutralization. According to the acid-resistant chelating resin combinational adjusting and controlling method for quality-divided recycling complex heavy metal, by stair-stepped adjusting and controlling of the pH value of wastewater and preferential combining of the acid-resistant chelating resin, selective separating and quality-divided recycling of the complex heavy metal in strong acid wastewater are realized, and remarkable environmental benefit and economic benefit are achieved.

Owner:南京华创环境技术研究院有限公司

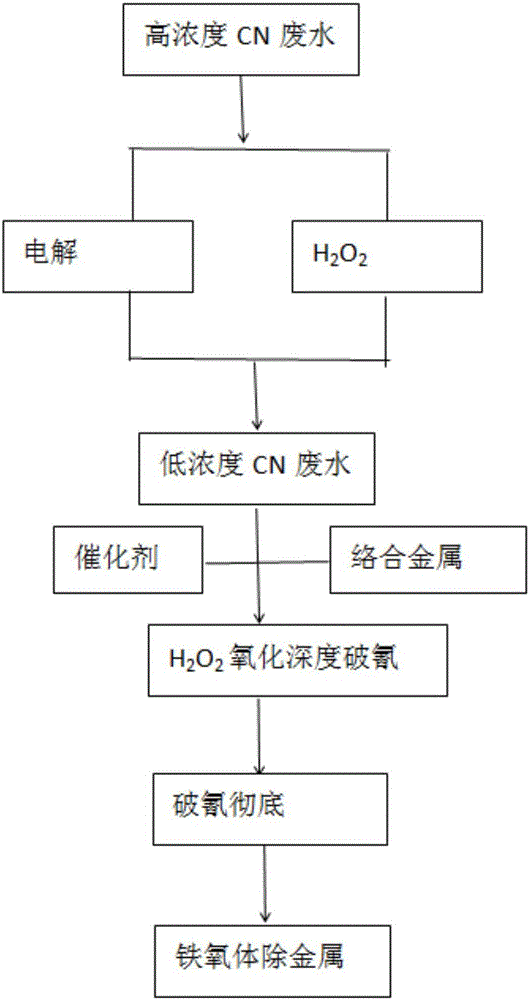

Method for removing heavy metal by carrying out cyanide breaking on high-concentration cyanide wastewater

ActiveCN106396205AAvoid follow-up issuesNo costWater contaminantsWaste water treatment from metallurgical processHigh concentrationEthylene diamine

The invention relates to a method for removing heavy metal by carrying out cyanide breaking on high-concentration cyanide wastewater. The method comprises the following steps: (1) feeding the high-concentration cyanide wastewater into an electrolytic bath, and carrying out electrolysis by using a direct current power supply under an alkaline condition; (2) in the electrolytic process, enabling content of cyanide to be gradually reduced, adding hydrogen peroxide to improve a reaction speed of the cyanide, and finally, carrying out electrolysis to obtain low-concentration cyanide wastewater; (3) regulating a pH value of the low-concentration cyanide wastewater obtained in the step (2) into 10 to 11, and adding EDTA (Ethylene Diamine Tetraacetic Acid) and a catalyst to perform reaction; (4) adding hydrogen peroxide into solution obtained in the step (3) to carry out deep cyanide breaking treatment; (5) for the wastewater subjected to complete cyanide breaking and obtained in the step (4), removing heavy metal in the solution by adopting a ferrite method. The method is simple to operate; not only is high-concentration cyanide removed, but also the wastewater subjected to cyanide breaking is subjected to deep treatment; particularly, ferricyanide reaches an emission standard.

Owner:盛隆资源再生(无锡)有限公司

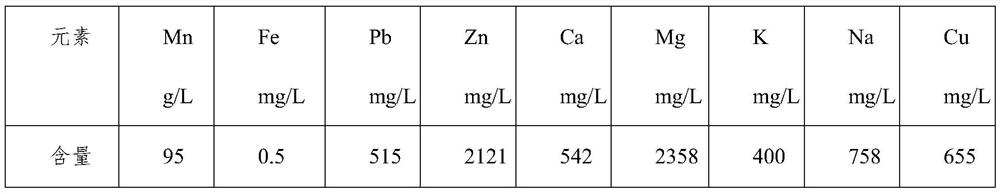

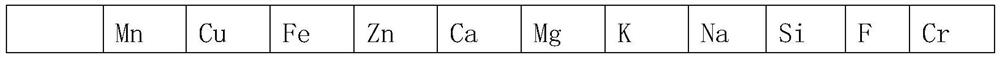

Process for preparing electronic-grade manganese sulfate without potassium-sodium-calcium-magnesium method

PendingCN112062159AEasy to solveSolve any problems brought inManganese sulfatesChemical productsSodium sulfate

The invention discloses a process for preparing electronic-grade manganese sulfate without a potassium-sodium-calcium-magnesium method in the technical field of batteries. According to the invention,by adopting a new thought, calcium, magnesium, potassium and sodium are left in a solution, manganese is separatedfrom the solution in the form of precipitate, and pure manganese salt precipitate is obtained after washing, so that all problems brought by fluorine are completely solved; various raw materials used in the method are inorganic chemical products, so that organic substances involved inextraction are avoided, hazardous wastes are not generated, and the investment of production equipment is saved; and the adopted manganese precipitation agent and wastewater thereof are sodium salt, other harmful heavy metals are completely treated at the front end, and sodium sulfate can be produced by crystallization or diluted to the discharge standard to be discharged according to the content.

Owner:福建省连城锰矿有限责任公司

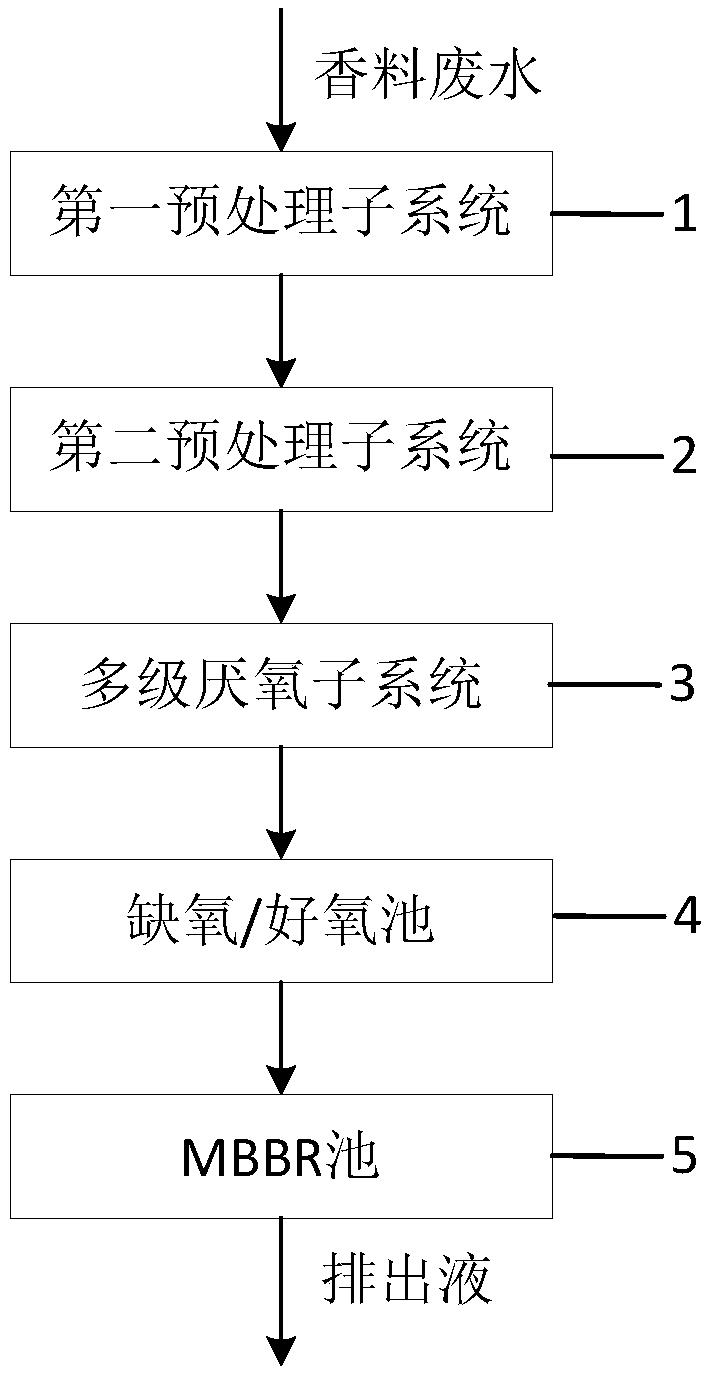

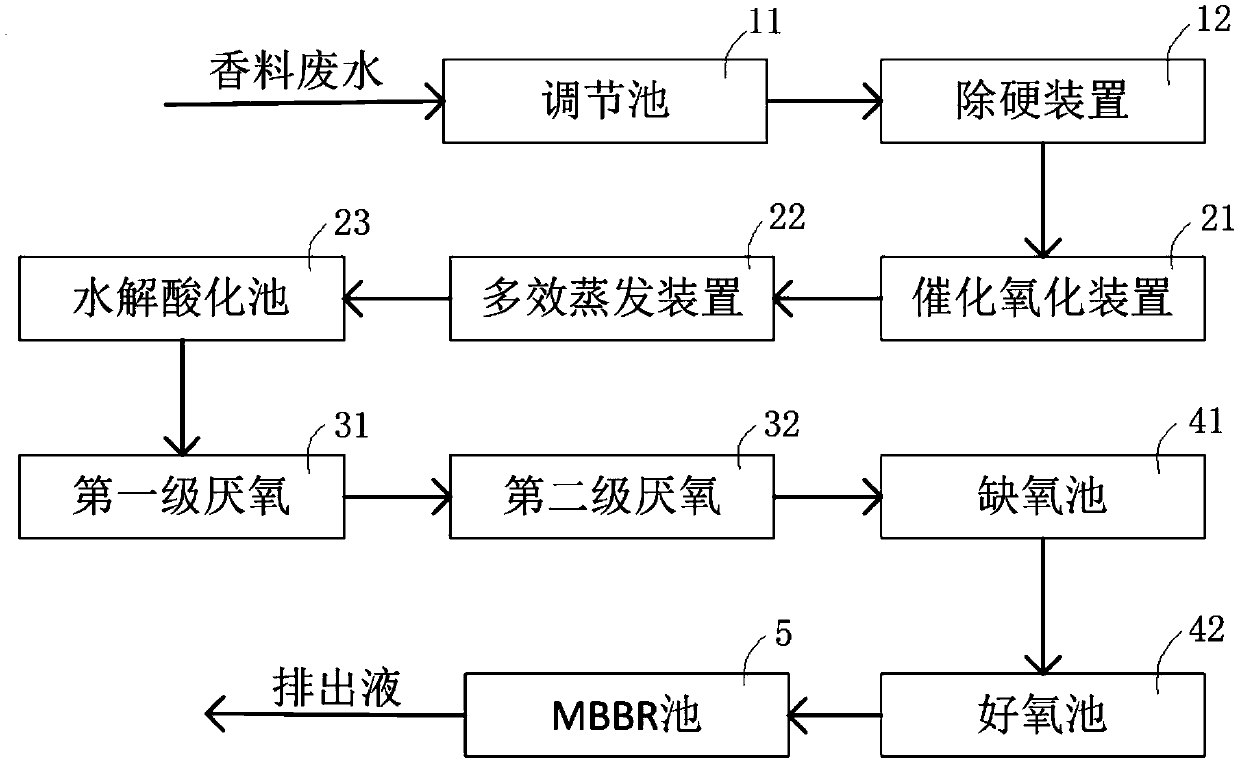

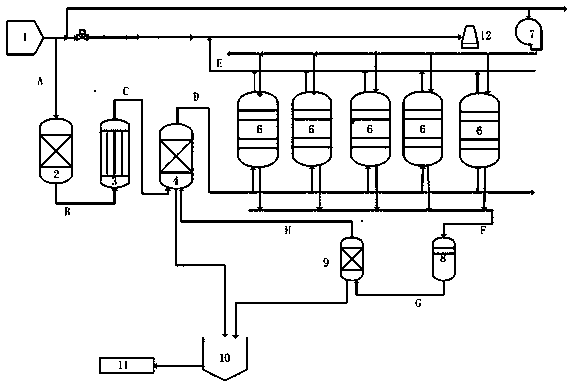

Spice wastewater treatment system

PendingCN109574386AHigh operating costsHazardous waste treatment costs are highSludge treatmentWater contaminantsMacromolecular SubstancesIndustrial wastewater treatment

The invention belongs to the technical field of wastewater treatment, and particularly relates to a spice wastewater treatment system. The spice wastewater treatment system comprises a first pretreatment subsystem, a second pretreatment subsystem, a multi-stage anaerobic subsystem, an anoxic / aerobic tank and an MBBR (moving bed biofilm reactor) tank. The first pretreatment subsystem is used for regulating the water quality and volume and removing the hardness in wastewater; the second pretreatment subsystem is used for reducing the chemical oxygen demand, improving biodegradability, removing salt, hydrolyzing insoluble organic matter into soluble organic matter, and converting macromolecular substances difficult to biodegrade into micromolecular substances liable to biodegrade; the multi-stage anaerobic subsystem is used for reducing the chemical oxygen demand and the organic matter content. The spice wastewater treatment system has the advantages that the treatment depth is increased,the amount of dangerous waste is significantly reduced, the evaporation amount is decreased, and the operation cost is saved by 20-30 yuan per ton of water.

Owner:安徽三江水务工程有限公司

Desulfurization and denitrification method for coke oven flue gas

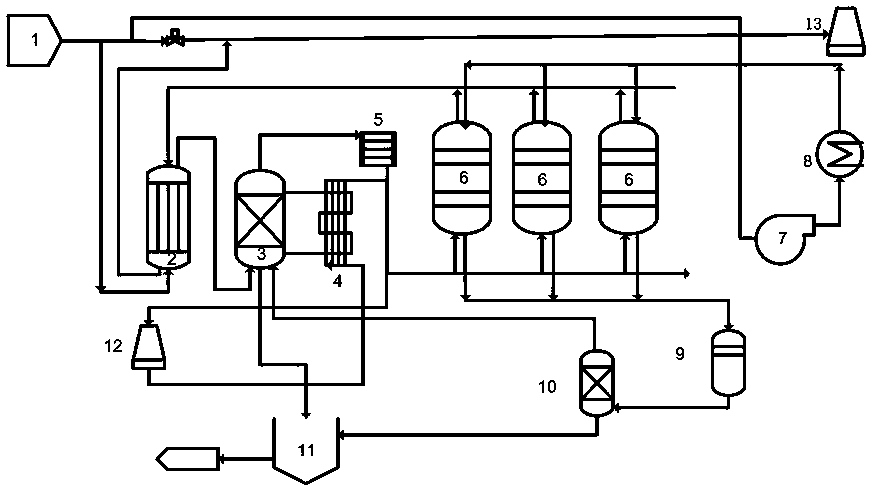

PendingCN109806742AGuaranteed uptimeLow costLighting and heating apparatusUsing liquid separation agentCooling towerSorbent

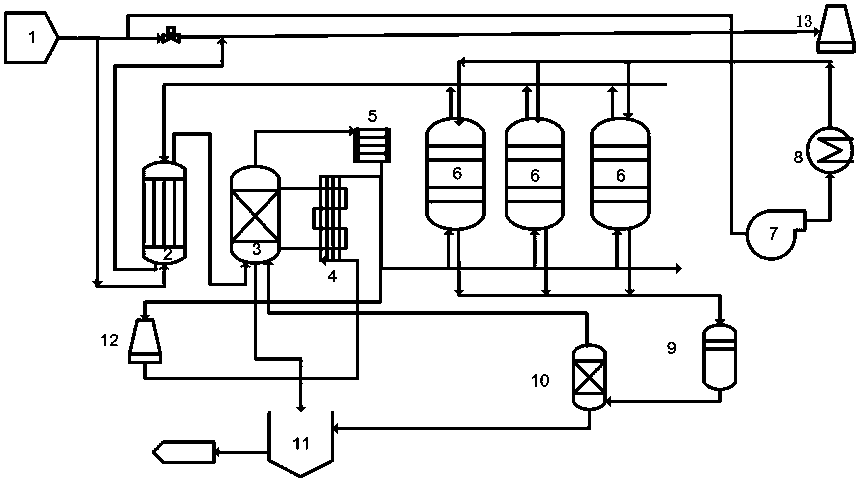

The invention relates to a desulfurization and denitrification method for coke oven flue gas, and aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the coke oven flue gas. The method involved in the invention is characterized by comprising the following steps: removing sulfide from coke oven gas or blast furnace gas to be burned in a coke oven before the coke oven gas or blast furnace gas enters the coke oven, and then enabling the coke oven gas or blast furnace gas to burn; recording the coke oven flue gas containing the sulfide and nitrogen oxides educed from a coke oven flue channel as logistics A, wherein the temperature of the logistics A is 120-320 DEG C; enabling the logistics A to enter a heat exchanger and form a logistics B after flue gas heat exchange with a chimney, wherein the temperature of the logistics B is 100-180 DEG C; enabling the logistics B to enter a cooling tower and form a logistics C after spraying, cooling and dust removal, wherein the temperature of the logistics C is 30-100 DEG C; enabling the logistics C to enter an adsorption tower containing a microcrystalline adsorbent and form a logistics D after adsorption of the sulfide and the nitrogen oxides; and enabling the logistics D to enter the chimney so as to be discharged after heat exchange with the logistics A and warming. Therefore, the above technical problems are well solved. The method can be applied to the industrial production of desulfurization and denitrification of the coke oven flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for sintering flue gas

PendingCN109499313AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasSulfide

The invention discloses a low-temperature desulfurization and denitrification method for sintering flue gas, relates to a desulfurization and denitrification method for the sintering flue gas, and mainly aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the sintering flue gas. The desulfurization anddenitrification method is characterized by removing nitrogen oxide and sulfide in the sintering flue gas by adopting an adsorption method, and performing salt-making treatment on the nitrogen oxide and sulfide in regenerated flue gas, so that the above problems are solved well. The desulfurization and denitrification method can be applied to the industrial production of desulfurization and denitrification of the sintering flue gas in iron and steel plants.

Owner:湖北申昙环保新材料有限公司

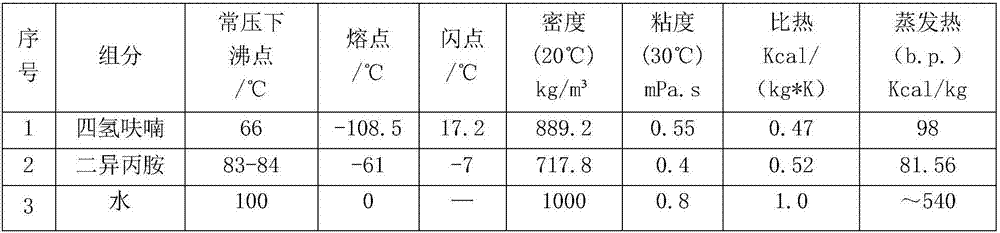

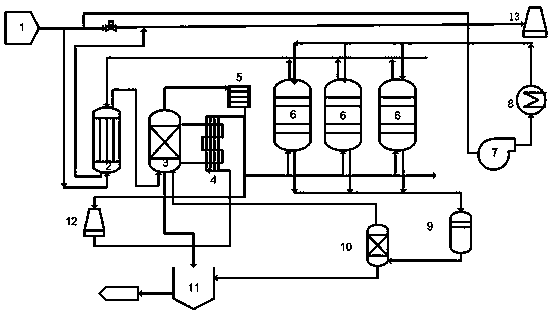

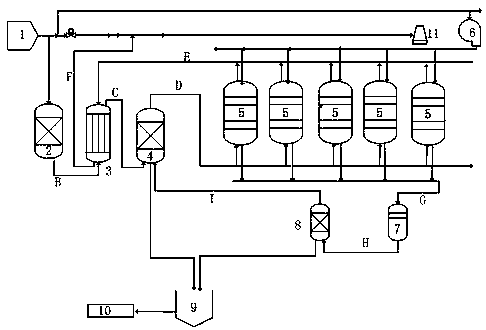

Environmental-protection cleaning device and process method for separating organic azeotropes

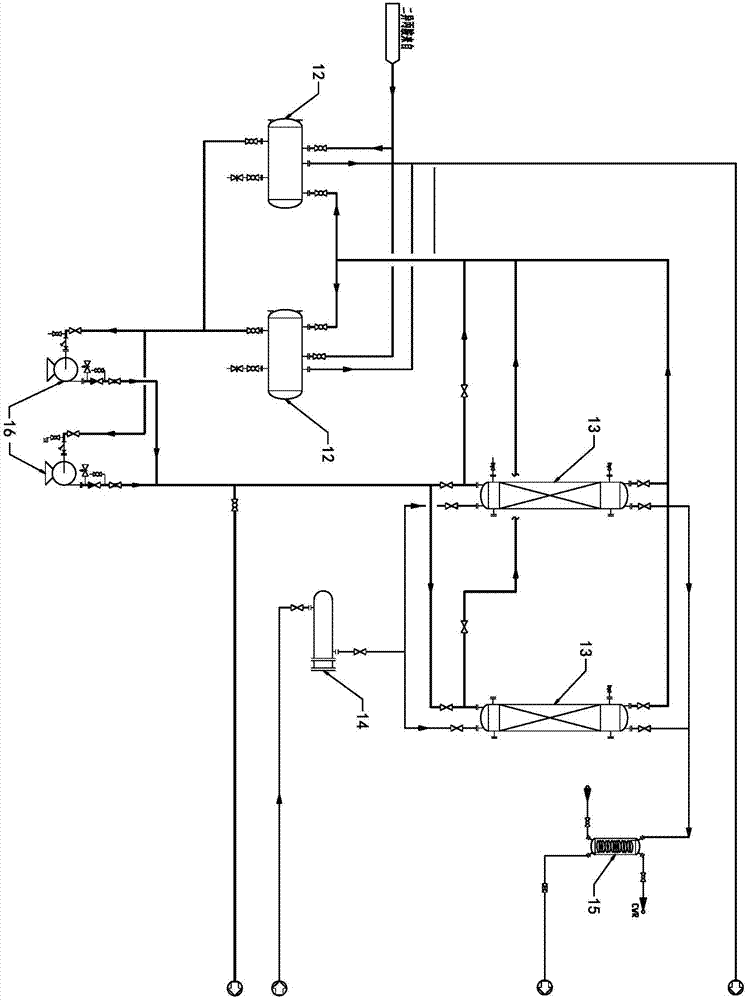

PendingCN107998678AAvoid bringing inNo hazardous wasteDistillation regulation/controlFractional distillationEnvironmentally friendlyEnvironmental resistance

The invention discloses an environmental-protection cleaning device and process method for separating organic azeotropes. According to the device, a rectifying kettle is arranged at the lower end of arectifying tower, the interior of the rectifying kettle is provided with a first heater, and the rectifying kettle communicates with the rectifying tower; the top of the rectifying tower communicateswith an inlet of a condenser; an outlet of the condenser communicates with a reflux ratio distributor; one end of the reflux ratio distributor communicates with the rectifying tower, and the other end of the reflux ratio distributor communicates with a first condenser inlet; at least one separation substance receiving tank is arranged, inlets of all the separation substance receiving tanks are jointly connected to a first condenser outlet, and outlets of all the separation substance receiving tanks are jointly connected with a tail cooler inlet; a tail cooler communicates with a tail coolingtank. A third component is added to two or more intermiscible components having minimum azeotropic composition or having an association phenomenon, the two separation material systems can be separated, no new hazardous wastes can be produced, new impurities can be prevented from being brought in, and the device and the method are clean and environmentally friendly.

Owner:烟台国邦化工机械科技有限公司

Sintering smoke gas low-temperature desulfurization and denitrification method

InactiveCN109513346AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationNitric oxideNitrogen oxide

The invention relates to a sintering smoke gas low-temperature desulfurization and denitrification method, which mainly solves the problems of high operation cost and secondary pollution generation ofthe existing sintering smoke gas desulfurization and denitrification. The method has the technical scheme that a microcrystalline material adsorption method is used for eliminating nitric oxides andsulfides in the sintering smoke gas; the nitric oxides and sulfides in the regenerated smoke gas are oxidized to be used as resources. The problems are well solved. The method can be used in the industrial production of steel and iron factory smoke gas desulfurization and denitrification.

Owner:山东洲蓝环保科技有限公司

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453660AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationNitrogen oxideNitric oxide

The invention relates to a low-temperature desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the low-temperature desulfurization and denitrification method of the boiler smoke, nitric oxide and sulfide in the boiler smoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to salt manufacturing treatment. According to the technical scheme, by adopting the low-temperature desulfurization and denitrification method of the boiler smoke, the problems are well solved, and the method can be used for industrial production of desulfurization and denitrification of the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method for coke oven flue gas

InactiveCN109464911AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention relates to a low-temperature desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The low-temperature desulfurization and denitrification method disclosed by the invention adopts the technical scheme that the coke oven flue gas containing sulfide and nitrogen oxide, induced from a coke oven flue, enters a denitrification tower containing a denitrification catalyst; the nitrogen oxide and the sulfide in the coke oven flue gas are removed according to a catalytic reduction and adsorption method; the nitrogen oxide and the sulfide in regenerated flue gas are subjected to salt preparation treatment, the problems are better solved; the method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method for coke oven flue gas

InactiveCN109464910AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationFlue gasCoke oven

The invention relates to a low-temperature desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The low-temperature desulfurization and denitrification method disclosed by the invention adopts the technical scheme that nitrogen oxide and sulfide in the coke oven flue gas are removed according to a microcrystalline material adsorption method; nitrogen oxide and sulfide in regenerated flue gas are oxidized and recycled, the technical problems are better solved. The method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Iodine battery device

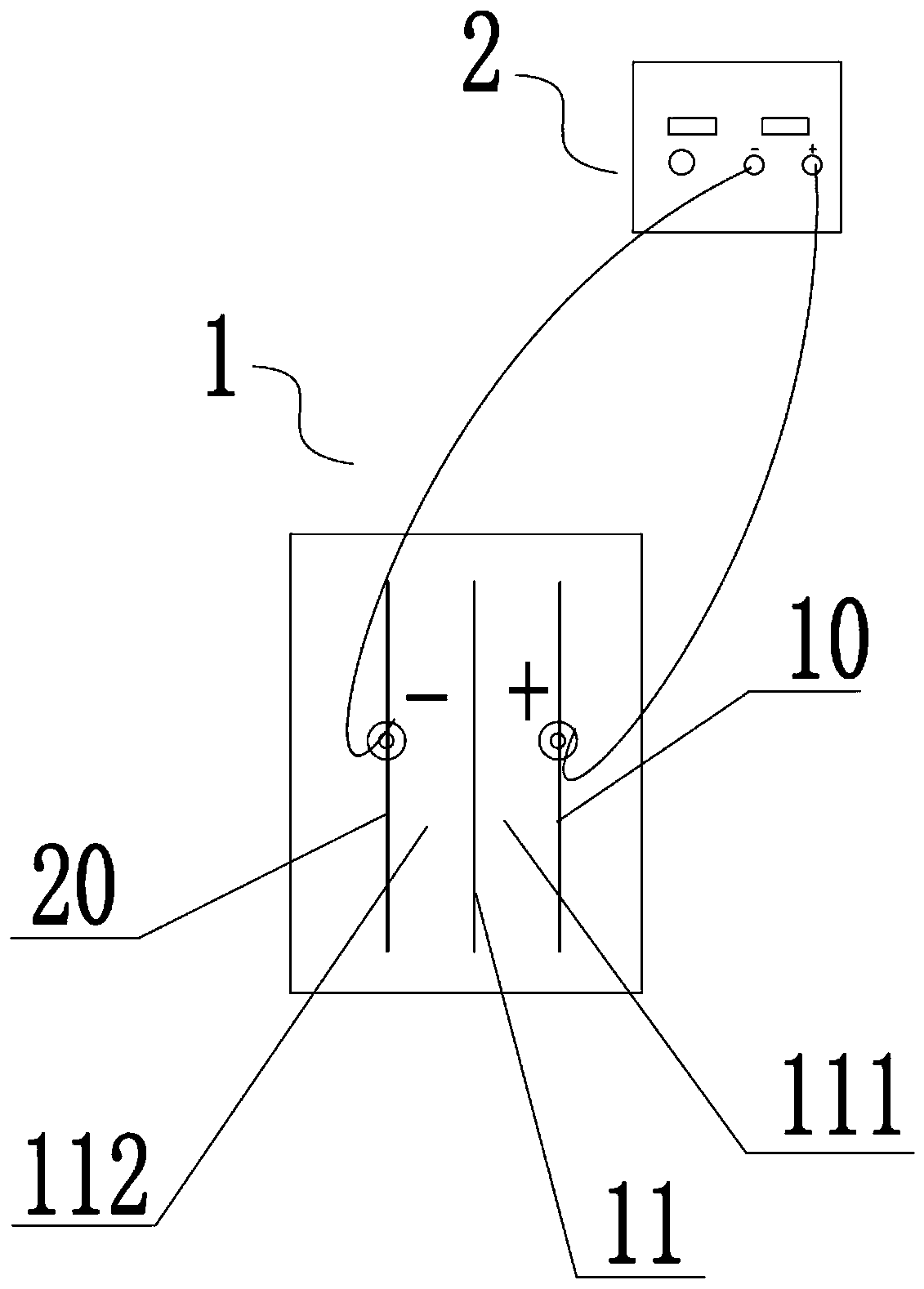

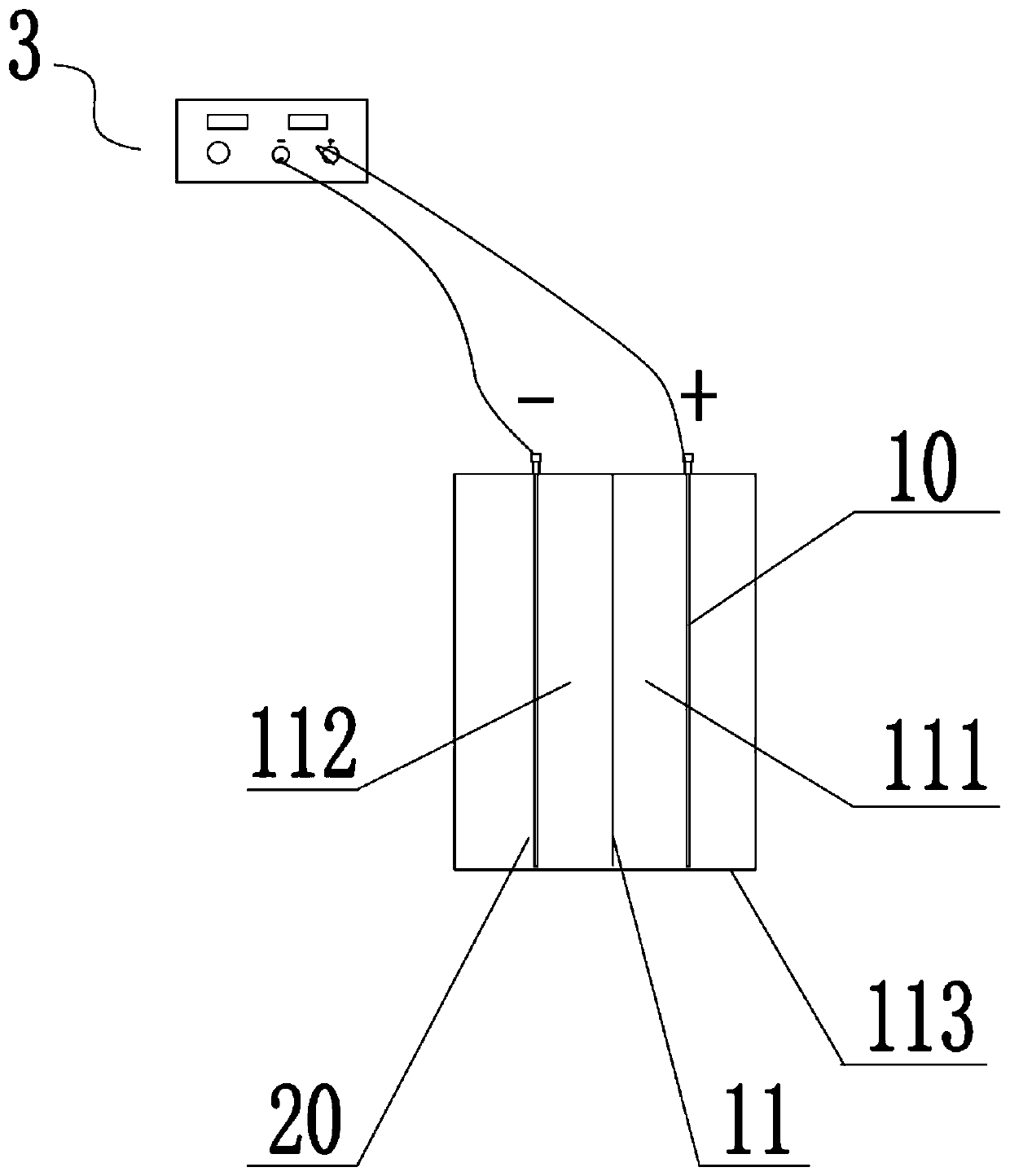

InactiveCN110416633AReliable and controllable reaction processNo loss of economic valueFinal product manufactureSecondary cellsNew energyIodic acid

The invention relates to an iodine battery device, and relates to the technical field of new energy. The technical problems of low efficiency, safety and environmental protection in the prior art aresolved. The iodine battery device provided by the invention comprises an iodine battery device. Iodine is used as the raw material of the iodine battery device. When charging is carried out, oxidationreaction occurs in a periodic acid chamber. Iodic acid is oxidized to periodic acid. In the hydroiodic acid chamber thereof, reduction reaction occurs, and elemental iodine is reduced to hydriodic acid. The iodine battery device is a discharge process which is the reverse reaction of the above reaction. The entire process can control the start and end points of reaction through a potential value.Iodine is a high-value raw material. After a battery is scrapped, the battery can be recycled. The iodine battery device prevents loss of economic value and hazardous waste, is conducive to social environmental protection, and prevents battery explosion.

Owner:SHANDONG RUIKE ENVIRONMENTAL TECH CO LTD

Pelletizing smoke gas low-temperature desulfurization and denitrification method

InactiveCN109513341AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationNitric oxideSulfide

The invention relates to a pelletizing smoke gas desulfurization and denitrification method, which mainly solves the problems of high operation cost and secondary pollution generation of the existingpelletizing smoke gas desulfurization and denitrification. The method has the technical scheme that an adsorption method is used for eliminating nitric oxides and sulfides in pelletizing smoke gas; the nitric oxides and sulfides in the regenerated smoke gas are subjected to salt preparation treatment. The problems are well solved. The method can be used in the industrial production of steel and iron factory smoke gas desulfurization and denitrification.

Owner:山东洲蓝环保科技有限公司

Treatment method of organic wastewater containing salts and phosphorus

InactiveCN110407387ALow costGood economic and environmental benefitsWater contaminantsTreatment involving filtrationFertilizerChemistry

The invention provides a treatment method of organic wastewater containing salts and phosphorus and belongs to the technical field of environmental resources. Organic amine gas, calcium salt solids and a salt-containing mother liquor are obtained through the reaction between calcium-containing alkaline substances and the organic wastewater containing salts and phosphorus; evaporation crystallization and high-temperature oxidation are carried out on the salt-containing mother liquor to obtain industrial sodium chloride; calcium phosphate is obtained through high-temperature oxidation of the calcium salt solids. The provided treatment method can carry out recycling treatment on all components in the wastewater, and obtained calcium phosphate can be sold as a fertilizer product. The providedtreatment method is low in cost, does not generate new hazardous wastes and has remarkable economic and environmental benefits.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

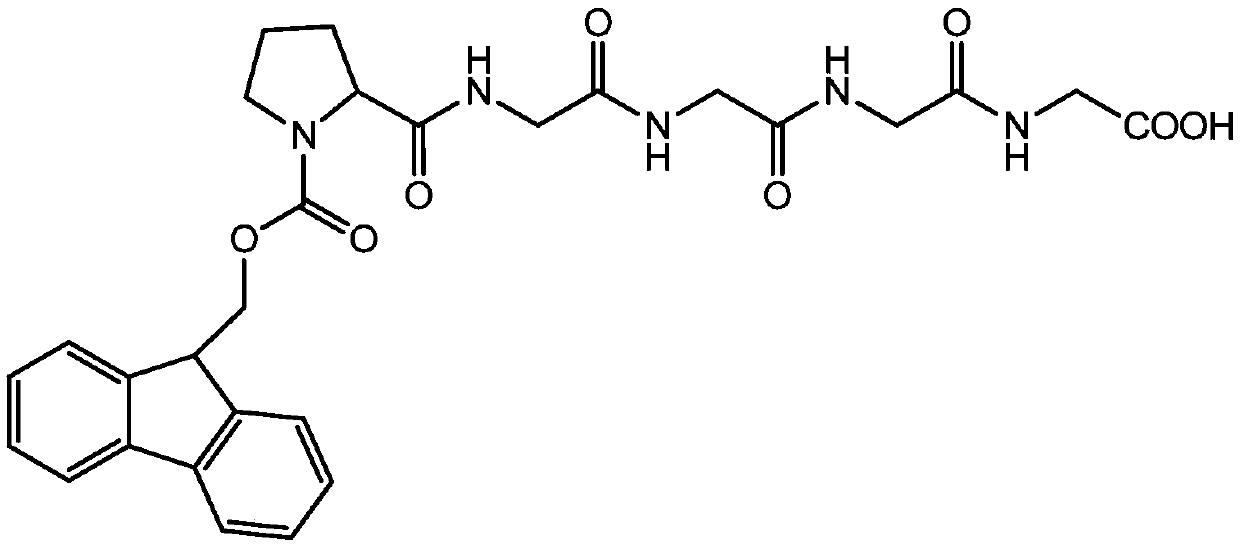

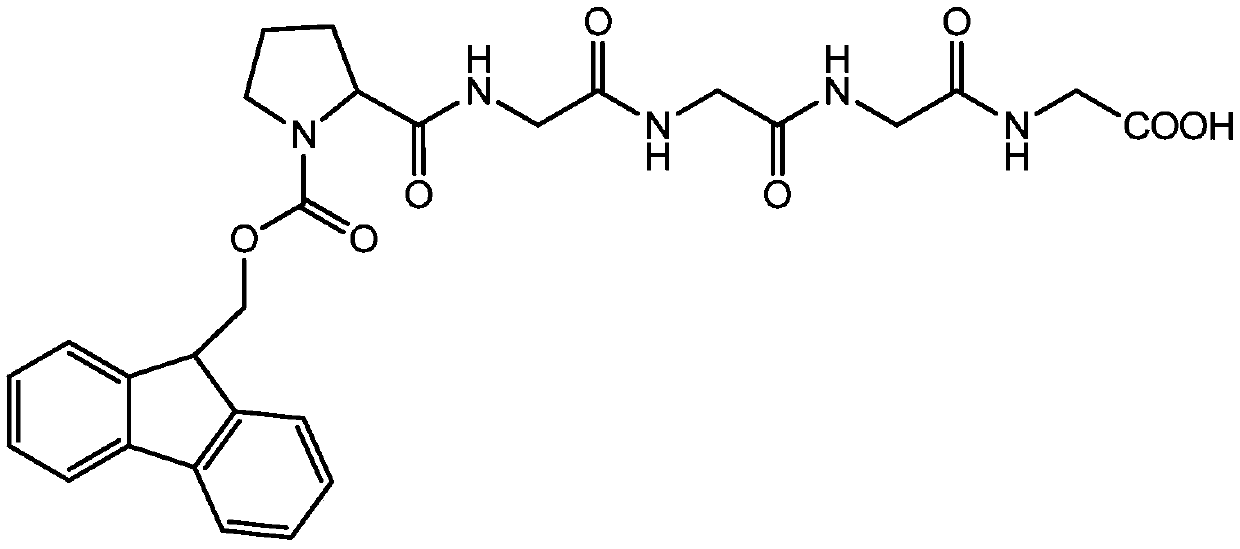

Technical method for synthesizing bivalirudin protected pentapeptide fragment by mass high-performance liquid chromatography method

ActiveCN110183532AReduce pollutionMild reaction conditionsPeptide preparation methodsBulk chemical productionHydrofluoric acidDipeptide

The invention relates to the technical field of bivalirudin, and particularly relates to a technical method for synthesizing bivalirudin protected pentapeptide fragment by a mass high-performance liquid chromatography method. According to the method, Fmoc-Pro-OSu is used as an initial raw material, is condensed with dipeptide to obtain a protected tripeptide; and the protected tripeptide is condensed with dipeptide, and recrystallization is performed to obtain the compound. The method has the advantage of mild reacting condition, the production requirement can be met by conventional productionconditions; the product is refined by adopting a crystallization method, has low cost, simple operation and high yield in comparison with column chromatography; and hydrofluoric acid and other fluorine-containing compounds are not use, and environmental pollution is small.

Owner:JINAN ASIA PHARMA TECH

Desulfurization and denitration method for boiler flue gas

PendingCN109499317AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasNitrogen oxide

The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solving the problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting the technical scheme that nitrogen oxides and sulfides are removed from the boiler flue gas by an adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to salt making treatment, the above problem is better solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Method for desulfurization and denitration of sintering flue gas

PendingCN109550393AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationFlue gasNitrogen oxide

The invention relates to a method for desulfurization and denitration of sintering flue gas. The problems that an existing technique for desulfurization and denitration of sintering flue gas has highoperation cost and secondary pollution are solved mainly. According to the technical scheme, an adsorption method is adopted to remove nitrogen oxides and sulfides in the sintering flue gas, and saltmanufacturing treatment is performed on nitrogen oxides and sulfides in regenerated flue gas, so that the problems are solved well; and the method can be applied to industrial production of desulfurization and denitration of flue gas in steel plants.

Owner:马广伟

Desulfurization and denitrification method for pelletizing flue gas

PendingCN109499307AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasNitrogen oxide

The invention relates to a desulfurization and denitrification method for pelletizing sintering flue gas, and mainly aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the pelletizing sintering flue gas. The method is characterized by removing nitrogen oxide and sulfide in the pelletizing sintering flue gas by adopting an adsorption method, and performing salt-making treatment on the nitrogen oxide and sulfide in regenerated flue gas, so that the above problems are solved well. The method can be applied to the industrial production of desulfurization and denitrification of flue gas in iron and steel plants.

Owner:湖北申昙环保新材料有限公司

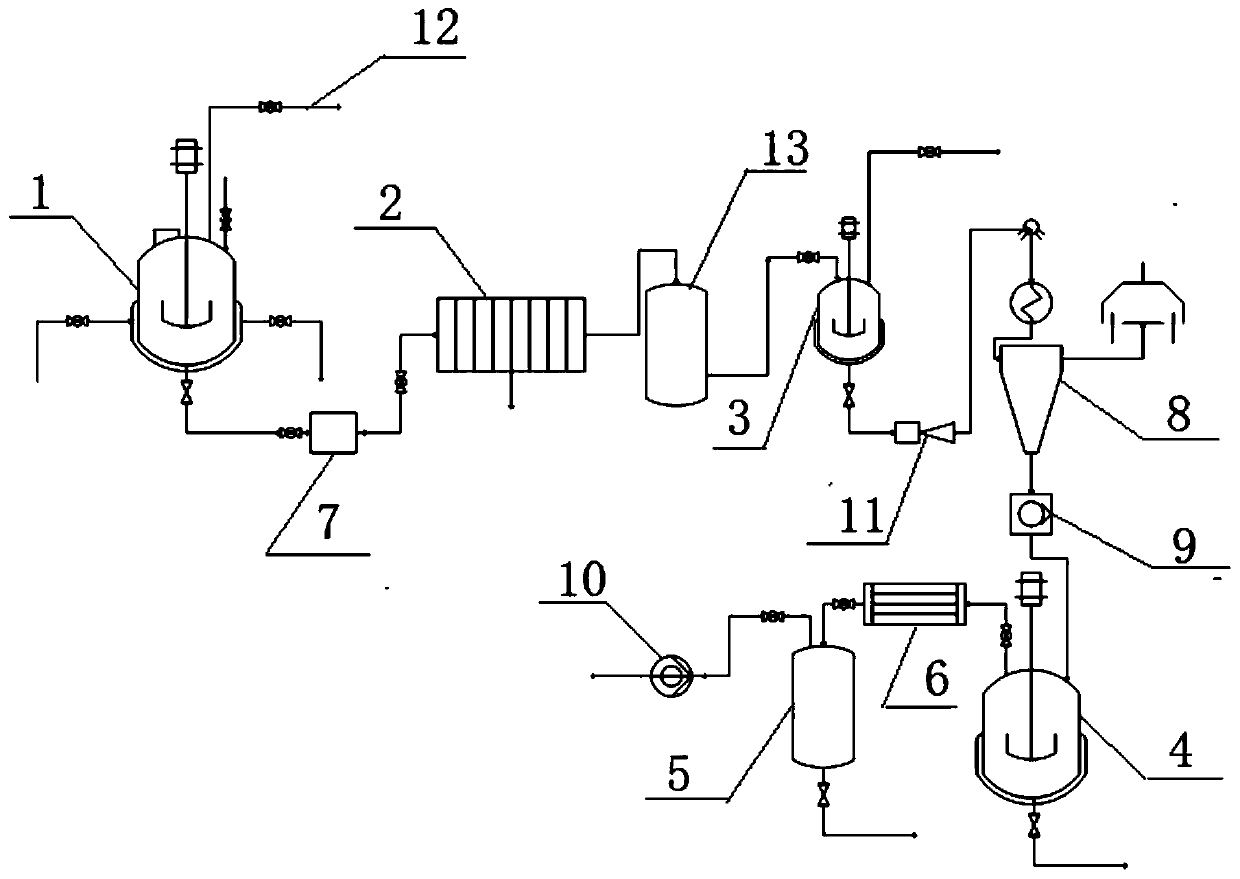

Device and method for recovering trifluoromethanesulfonic acid from trifluoromethanesulfonic acid-containing wastewater

ActiveCN111116431AGood market demand and economic benefitsNo hazardous wasteOrganic chemistryOrganic compound preparationEnvironmental chemistryFine chemical

The invention relates to a device and a method for recovering trifluoromethanesulfonic acid from trifluoromethanesulfonic acid-containing wastewater, and belongs to the technical field of fine chemical engineering and environmental protection. According to the device, a neutralization reaction kettle is connected with a filter, wherein the filter is connected with a buffer tank, the buffer tank isconnected with a drying device, the drying device is connected with an acidification reaction kettle, the acidification reaction kettle is connected with a condenser, the condenser is connected witha receiving tank, and the receiving tank is provided with a vacuum connector connected with a vacuum pump. By adopting the device and the method provided by the invention, trifluoromethanesulfonic acid can be recovered from trifluoromethanesulfonic acid-containing wastewater under the conditions of lower temperature and pressure. The process is of one-way circulation, wherein no hazardous waste, no pollution and no hazardous gas are generated, and trifluoromethanesulfonic acid-containing wastewater which is difficult to treat at the present stage is treated at the same time; the recovered trifluoromethanesulfonic acid can be reused, so that the method has good market requirements and economic benefits.

Owner:PERIC SPECIAL GASES CO LTD

Low-temperature comprehensive desulfurization and denitration method for boiler flue gas

PendingCN109499310ALow costGuaranteed uptimeGas treatmentUsing liquid separation agentBoiler furnaceFlue gas

Low-temperature comprehensive desulfurization and denitration method for boiler flue gas. The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solving the problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting thetechnical scheme that coke-oven gas or blast furnace gas entering a boiler furnace for combustion is subjected to sulfide removal prior to entering a coke oven and then is burnt, nitrogen oxides andsulfides are removed from the boiler flue gas by an adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to salt making treatment, the above problem isbetter solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453649AGuaranteed uptimeLow costGas treatmentDispersed particle separationSulfideNitrogen oxide

The invention relates to a desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the desulfurization and denitrification method of the boiler smoke, for coke oven gas or blast furnace gas which enters a boiler for burning, before the coke oven gas or the blast furnace gas enters the boiler, sulfide is removed at first, then burning is conducted, nitric oxide and the sulfide in the boiler smoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to salt manufacturing treatment. According to the technical scheme, by adopting the desulfurization and denitrification method of the boiler smoke, the problems are well solved, and the method can be used for industrial production of desulfurization and denitrification of the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453650AGuaranteed uptimeLow costGas treatmentDispersed particle separationResource utilizationNitric oxide

The invention relates to a desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the desulfurization and denitrification method of the boiler smoke, micro-crystal materials are adopted, for coke oven gas or blast furnace gas which enters a boiler for burning, before the coke oven gas or the blast furnace gas enters the boiler, sulfide is removed at first, then burning is conducted, nitric oxide and the sulfide in the boilersmoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to oxidization for resource utilization. According to the technical scheme, by adoptingthe desulfurization and denitrification method of the boiler smoke, the technical problems are well solved, and the method can be used for industrial production of desulfurization and denitrificationof the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Low temperature desulfurization and denitrification method of coke oven flue gas

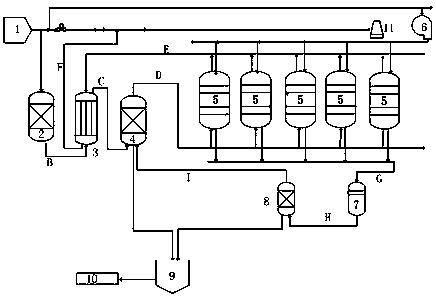

InactiveCN109731463AExtended service lifeImprove adsorption capacityDispersed particle separationCooling towerSorbent

The invention relates to a desulfurization and denitrification method of coke oven flue gas and mainly solves the problem that existing desulfurization and denitrification operation for coke oven fluegas has high cost and causes secondary pollution. According to the technical scheme, the method herein includes: allowing coke oven flue gas to enter a denitrifying column with a denitrifying catalyst, allowing the flue gas to enter a cooling column after catalytic reduction, cooling by spraying, removing dust, allowing the flue gas to enter an adsorbing column with a microcrystalline adsorbent to adsorb sulfides and oxygen nitrides, and discharging the flue gas via a chimney; subjecting the oxygen nitrides and sulfides in the regenerated flue gas to salt manufacturing. The above problem is well solved by using the method; the method is suitable for the industrial production of desulfurization and denitrification of coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

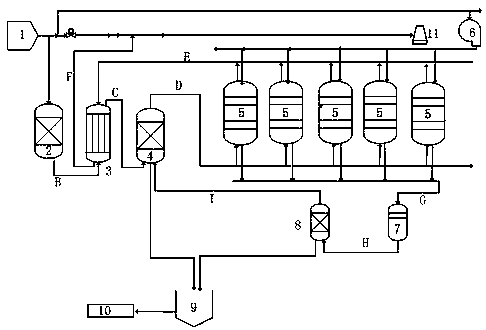

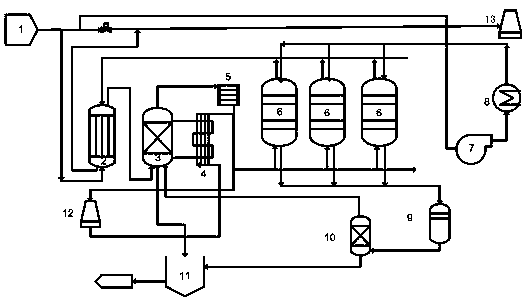

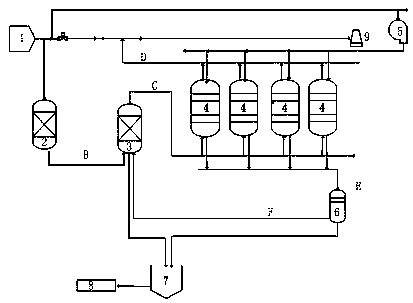

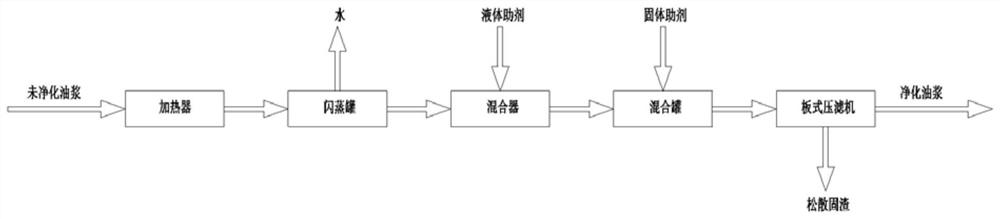

Method for removing solid impurities of catalytic slurry oil through low-temperature coalescence

ActiveCN112480959AEasy to removeNo risk of contaminationTreatment with plural serial refining stagesPtru catalystSlag

The invention discloses a method for removing solid impurities of catalytic slurry oil by low-temperature coalescence, which comprises the steps of heating, dehydrating, adding a liquid assistant, mixing, heating a solid assistant, mixing, and carrying out solid-liquid separation, thereby obtaining the purified catalytic slurry oil with low ash content in which solid impurities are removed. According to the invention, through the combined action of the liquid auxiliary agent and the solid auxiliary agent, tiny catalyst solid particles are aggregated into large particles, so that impurities areeasy to remove; the solid impurities in the catalytic slurry oil are separated out in a solid form, the process technology is novel, the operation is easy, and continuous separation can be achieved;the separated solid slag is in a loose solid state in appearance, is convenient to mix and burn with fire coal, and is environment-friendly; no concentrated solution or other liquid hazardous waste isgenerated, and no environmental pollution risk is caused; and the method has the advantages of mild process conditions, simple equipment, easy operation, continuous production, thorough solid-liquidseparation and high finished product yield, and the yield of the purified catalytic slurry oil obtained after separation reaches 99% or above.

Owner:MAOMING YINGPENG ELECTROMECHANICAL EQUIP

Low-temperature desulfurization and denitration method for boiler flue gas

PendingCN109499318AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentProcess engineeringEngineering

Low-temperature desulfurization and denitration method for boiler flue gas. The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solvingthe problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting the technical scheme that nitrogen oxides and sulfides are removed from the boiler flue gas by a microcrystalline material adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to oxidation for resource-converting utilization, the above technical problem is better solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for pelletizing exhaust gas

InactiveCN109513350AExtended service lifeImprove adsorption capacityGas treatmentLighting and heating apparatusNitrogen oxideEngineering

The invention relates to a desulfurization and denitrification method for pelletizing exhaust gas. The method is mainly adopted for solving the problems of high running cost and secondary pollution ofpresent desulfurization and denitrification for pelletizing exhaust gas. According to the invention, the technical scheme of adopting an absorbing method for removing nitric oxide and sulfide from pelletizing exhaust gas and then performing salt-production treatment on nitric oxide and sulfide in the regenerated exhaust gas is adopted for solving the problems. The method can be applied to industrial production of exhaust gas desulfurization and denitrification in steelworks.

Owner:山东洲蓝环保科技有限公司

Low-temperature desulfurization and denitrification method for coke oven flue gas

PendingCN109806741AExtended service lifeImprove adsorption capacityLighting and heating apparatusUsing liquid separation agentResource utilizationSulfide

The invention provides a low-temperature desulfurization and denitrification method for coke oven flue gas, relates to the desulfurization and denitrification method for the coke oven flue gas, and aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the coke oven flue gas. The method involved in the invention is characterized in that a microcrystalline material adsorption method is adopted to remove sulfide from coke oven gas or blast furnace gas to be burned in a coke oven before the coke oven gasor blast furnace gas enters the coke oven, and then the coke oven gas or blast furnace gas burns; an adsorption method is then used to remove nitrogen oxides and the sulfide from the coke oven flue gas; and oxidation is performed on the nitrogen oxides and the sulfide in the regenerated flue gas to realize resource utilization. Therefore, the above technical problems are well solved. The method can be applied to the industrial production of desulfurization and denitrification of the coke oven flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for sintering exhaust gas

InactiveCN109513349AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationExhaust gasNitric oxide

Owner:山东洲蓝环保科技有限公司

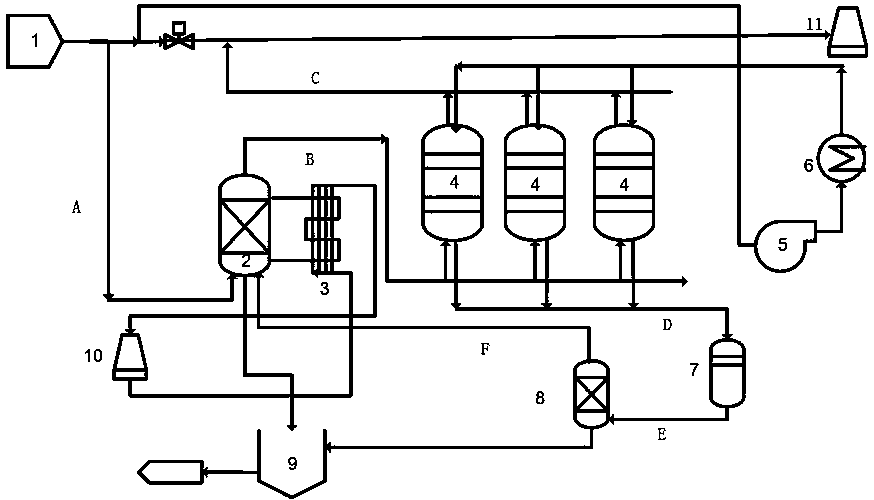

Desulfurization and denitrification method for coke oven flue gas

InactiveCN109464906AGuaranteed uptimeLow costGas treatmentDispersed particle separationCooling towerSorbent

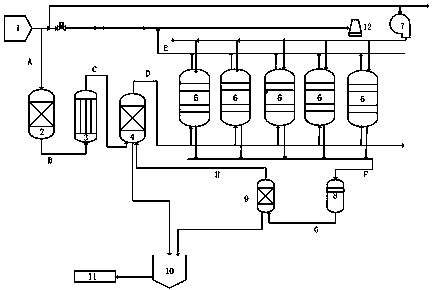

The invention relates to a desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The desulfurization and denitrification method disclosed by the invention adopts the technical scheme that sulfide is removed before the coke oven gas or blast furnace gas enters a coke oven and then the coke oven gas is burnt; the method comprises the following steps: the coke oven gas containing the sulfide and nitrogen oxide,induced from the coke oven flue, is marked as a material flow A; the material flow A is subjected to waste heat utilization to produce steam, and the cooled flue gas forms a material flow B; the material flow B enters a heat exchanger, and is subjected to heat exchange with flue gas from a chimney to form a material flow C; the material flow C enters the cooling tower for cooling and dedusting toform a material flow D; the material flow D enters the adsorption tower containing a microcrystalline adsorbent for adsorbing the sulfide and the nitrogen oxide to form a material flow E; the material flow E is subjected to heat exchange with the material flow C, is heated up and then enters the chimney for emission, the problems are better solved; the method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com