Device and method for recovering trifluoromethanesulfonic acid from trifluoromethanesulfonic acid-containing wastewater

A technology for trifluoromethanesulfonic acid and wastewater, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve problems such as waste of raw materials, and achieve good market demand and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

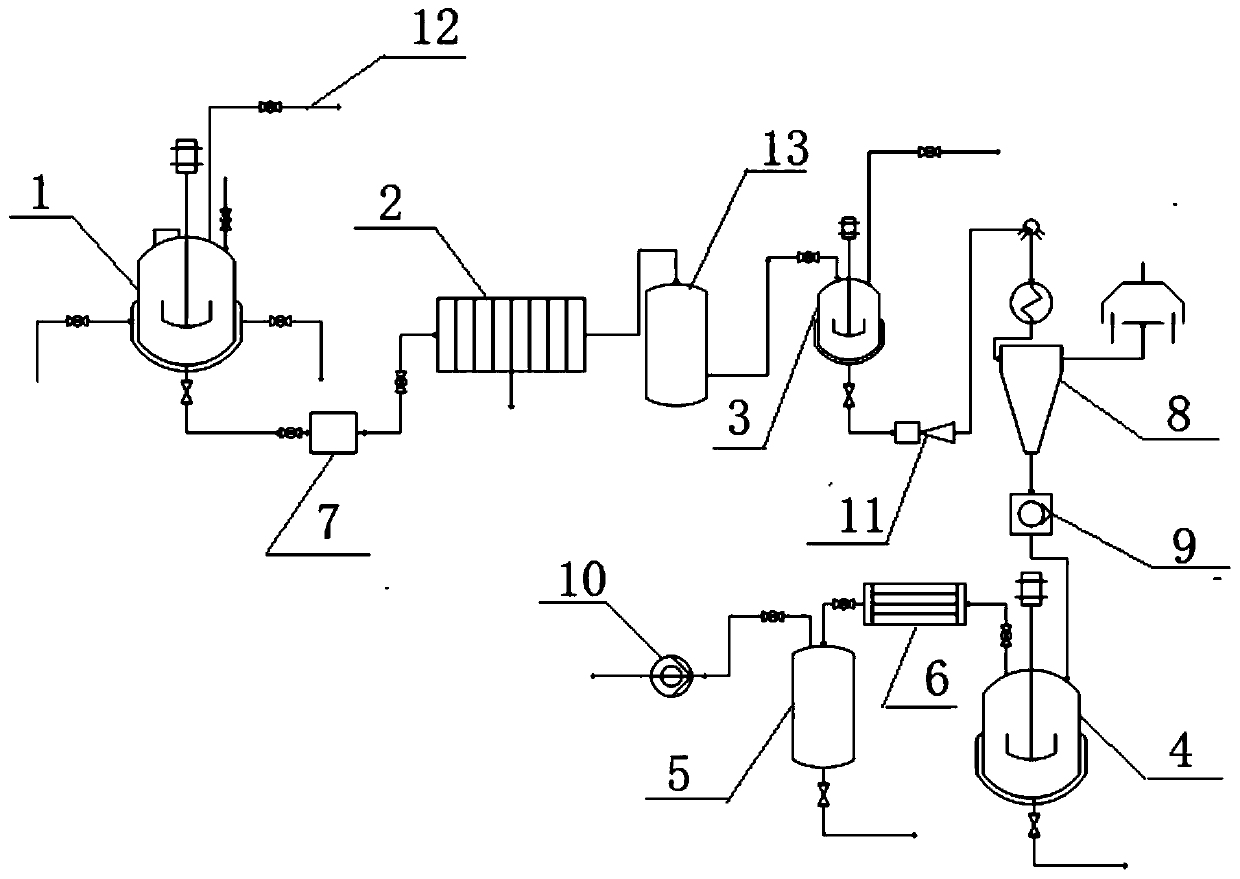

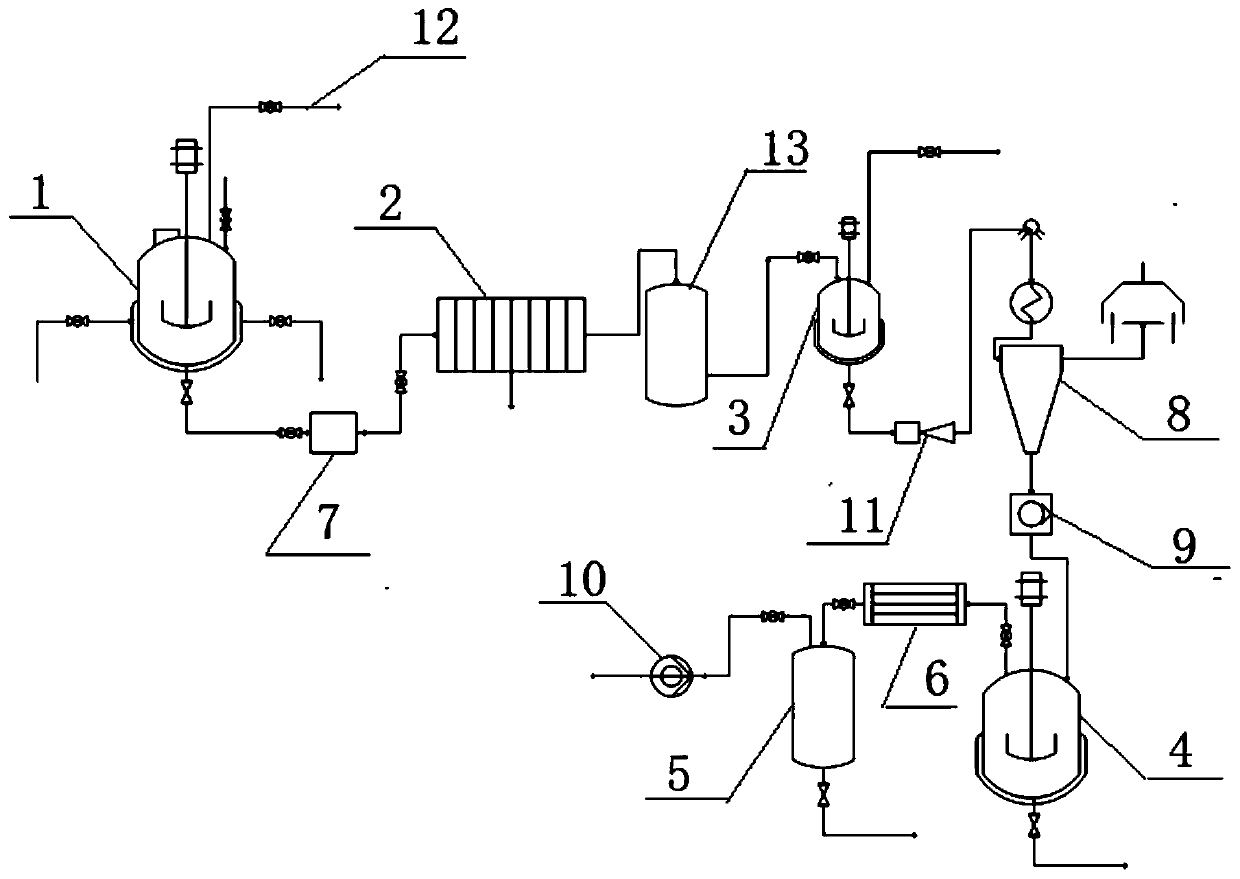

[0035] A device for recovering trifluoromethanesulfonic acid from trifluoromethanesulfonic acid-containing wastewater, the trifluoromethanesulfonic acid-containing wastewater is prepared by the reaction method of trifluoromethanesulfonic acid and phosphorus pentoxide to trifluoromethanesulfonic anhydride Produced in the process, the main components are: pyrophosphoric acid, trifluoromethanesulfonic acid and trace amounts of HF, H 2 SO 4 and other impurities; the device includes: neutralization reactor 1, filter 2, concentration kettle 3, acidification reactor 4, receiving tank 5, condenser 6, diaphragm pump 7, drying device 8, feeder 9, vacuum pump 10 , screw pump 11, vent pipe 12 and buffer tank 13, such as figure 1 shown.

[0036] Wherein, the neutralization reaction kettle 1 is provided with a vent pipe 12, and the vent pipe 12 remains open during the recovery process, so as to prevent the internal pressure of the still from rising due to the heat release in the neutraliz...

Embodiment 2

[0041] A method for reclaiming trifluoromethanesulfonic acid from waste water containing trifluoromethanesulfonic acid, said method adopts a device for reclaiming trifluoromethanesulfonic acid from waste water containing trifluoromethanesulfonic acid described in Example 1 to carry out ,Proceed as follows:

[0042] (1) The volume of neutralization reactor 1 is 1m 3, add calcium hydroxide 150kg to it, then add wastewater containing trifluoromethanesulfonic acid, add 0.5m 3 , put condensed water into the jacket of the neutralization reaction kettle 1 to ensure that the temperature in the kettle is 20°C, and at the same time, keep stirring the mixed material liquid during the neutralization reaction, and keep the vent pipe 12 of the neutralization reaction kettle 1 open , to avoid the pressure increase caused by the neutralization reaction, the vent pipe 12 is connected to the corresponding gas treatment device; during the reaction, the pH value of the mixed material liquid is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com