Process for preparing electronic-grade manganese sulfate without potassium-sodium-calcium-magnesium method

An electronic grade, manganese sulfate liquid technology, applied in the direction of manganese sulfate, can solve the problems of difficult to purchase, high cost, expensive manganese fluoride, etc., and achieve the effect of saving production equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

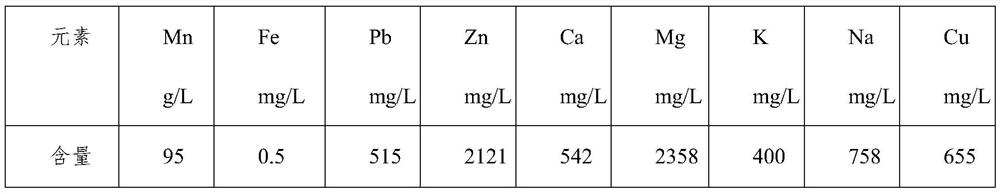

[0044] Embodiment: 1, be processed into 120 order fine powder 200g with manganese-containing 35% manganese dioxide ore and the manganese sulfide concentrate 100g that contains manganese 50%, sulfur 25% of flotation gained in 1.5L 1.5mol / L sulfuric acid solution 1.3L of crude manganese sulfate solution was obtained by acid leaching at temperatures above 85°C, and the pH at the end point was 2.5; 23.5g of lime was added to adjust the pH of the manganese sulfate to about 5.0 to remove iron impurities, and 1.26L of iron-removing manganese sulfate solution was obtained by filtration, with the indicators as follows :

[0045]

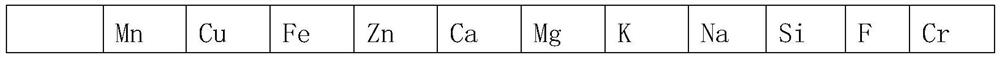

[0046] 2. Add 18.2g of 63% industrial-grade barium sulfide to the manganese sulfate solution obtained in the previous step, react at 60°C for 1 hour, filter, and then filter after standing for 24 hours to obtain 1.1L of purified manganese sulfate solution. The obtained indicators are as follows:

[0047] 3. Use the above manganese sulfate solution to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com