Method for desulfurization and denitration of sintering flue gas

A sintering flue gas, desulfurization and denitrification technology, applied in the field of desulfurization and denitrification, can solve the problems of high operating cost and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1.6 million cubic meters of flue gas at 240°C, with a nitrogen oxide content of 500mg / m 3 , the sulfide content is 200 mg / m 3 , the flue gas enters the denitrification tower, and at 240°C, under the action of the ZSM-5 molecular sieve catalyst, the nitrogen oxides are reduced to nitrogen, and the flue gas after the reaction enters the waste heat sintering to generate steam, and the flue gas temperature drops to about 180°C; then the flue gas The gas enters the self-heat exchanger and exchanges heat with the cold flue gas entering the chimney, and the temperature drops to about 110°C; the flue gas at 110°C is cooled to 50°C by spraying, and the spray water is recycled, and part of the waste water is neutralized. Biochemical removal system; the cooled flue gas passes through the demisting equipment and enters the adsorption tower; three 200m 3 The adsorption tower, two open and one standby, each adsorption tower is filled with 120m 3 Microcrystalline material, total 360...

Embodiment 2

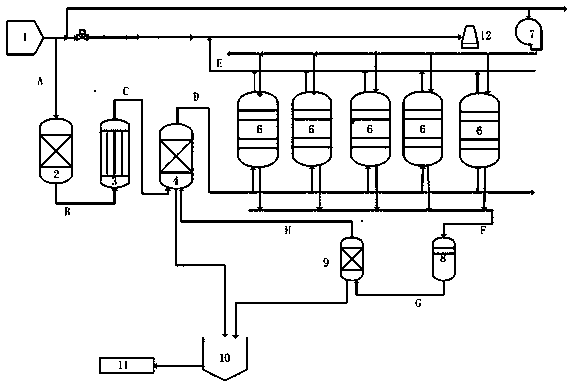

[0052] The specific implementation is as attached figure 1 The shown device flow, 1.5 million cubic meters of flue gas at 260°C, the nitrogen oxide content is 400mg / m 3 , the sulfide content is 100 mg / m 3 , the flue gas enters the denitration tower, at 240°C, under the action of ZSM-5 molecular sieve catalyst, the nitrogen oxides are reduced to nitrogen, and the flue gas after the reaction enters the waste heat sintering to generate 150°C steam, and the flue gas temperature drops to about 140°C; Then the flue gas enters the spray and cools down to 40°C, the spray water is recycled, and part of the wastewater is neutralized before going to the biochemical system; the cooled flue gas passes through the demisting equipment and enters the adsorption tower; three 200m 3 The adsorption tower, two open and one standby, each adsorption tower is filled with 120m 3 Microcrystalline material, total 360 m 3 Microcrystalline material ZSM-5 molecular sieve; the specification of the adsor...

Embodiment 3

[0054] The specific implementation is as attached figure 1 The shown device process, 1.4 million cubic meters of flue gas at 300°C, the nitrogen oxide content is 450mg / m 3 , the sulfide content is 200 mg / m 3 , the flue gas enters the denitrification tower, and at 300°C, under the action of the copper-supported ZSM-5 molecular sieve catalyst, the nitrogen oxides are reduced to nitrogen, and the flue gas after the reaction enters the waste heat sintering to generate steam at 160°C, and the flue gas enters the self-exchange The heater exchanges heat with the cold flue gas entering the chimney, and the temperature drops to about 110°C; the temperature of the flue gas at 110°C is reduced to about 110°C through the flue gas; the temperature of the flue gas at 110°C is cooled to 50°C by spraying, and the spraying The water is recycled, part of the waste water is neutralized, and then goes to the biochemical system; the cooled flue gas passes through the demisting equipment and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com