Patents

Literature

77results about How to "Improve adsorption accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

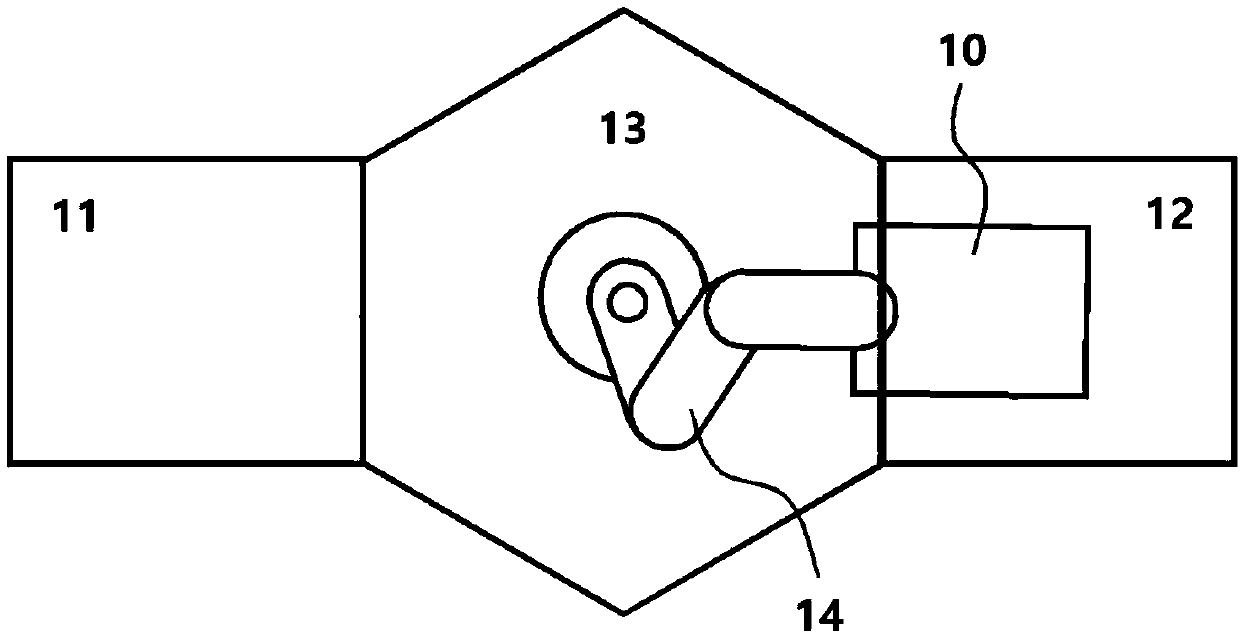

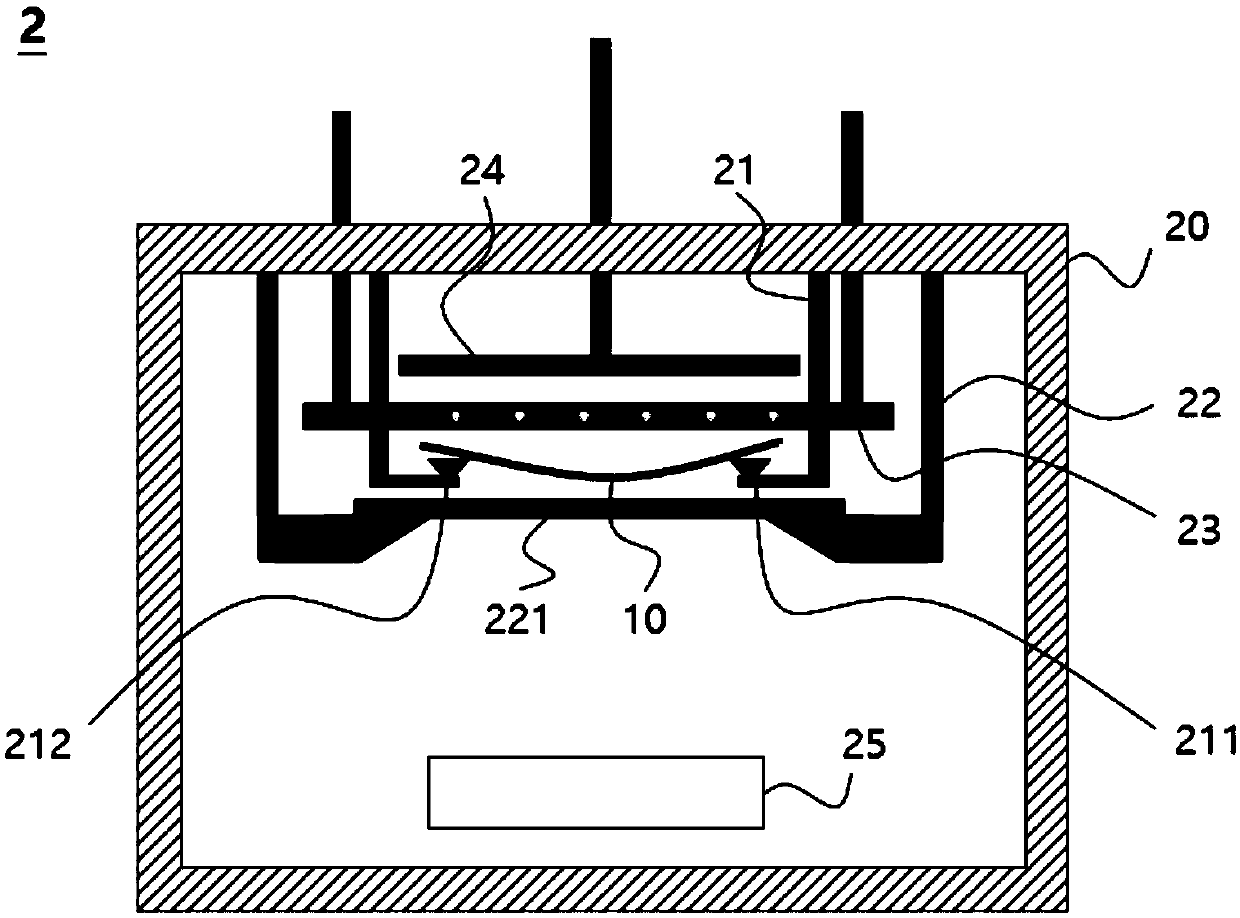

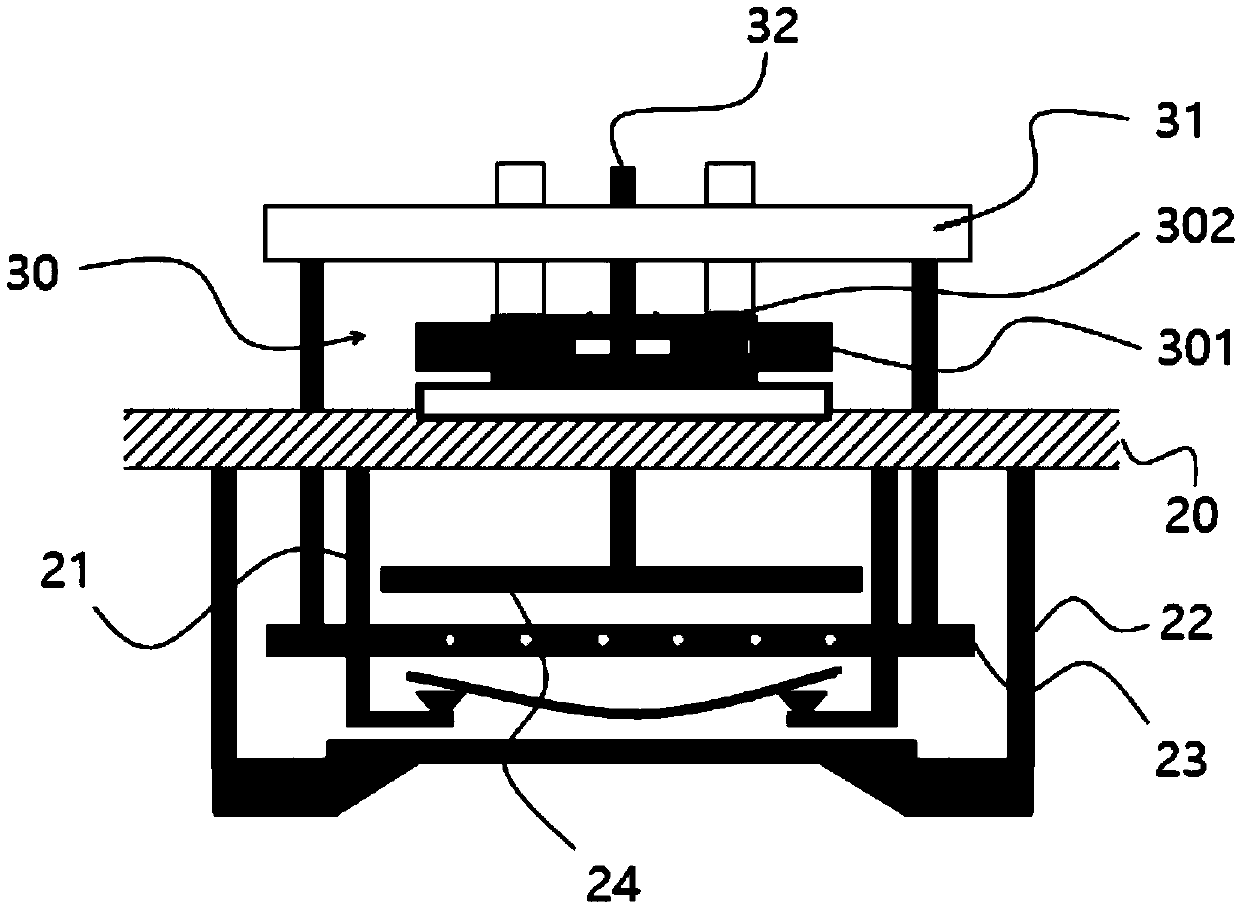

Film forming apparatus, film forming method and manufacturing method of electronic device

ActiveCN109837504AAdjust relative positionImprove adsorption accuracyVacuum evaporation coatingSputtering coatingMagnetic tension forceEngineering

The invention provides a film forming apparatus, a film forming method, and an electronic device manufacturing method. The film forming apparatus according to the present invention is used for forminga vapor deposition material on a substrate via a mask, and includes: a vacuum chamber defining a space in which a vapor deposition process is performed; the substrate adsorption mechanism is arrangedin the vacuum chamber and is used for adsorbing a substrate; the magnetic force applying mechanism is arranged above the substrate adsorbing mechanism in the vacuum chamber and is used for applying magnetic force to the mask; and an alignment station, the alignment table is arranged on the first outer surface of the vacuum chamber; and a rotation mechanism for moving or rotating the substrate suction mechanism and the magnetic force application mechanism in at least one of a first direction, a second direction intersecting with the first direction, and a rotation direction with a third direction intersecting with the first direction and the second direction as an axis.

Owner:CANON TOKKI CORP

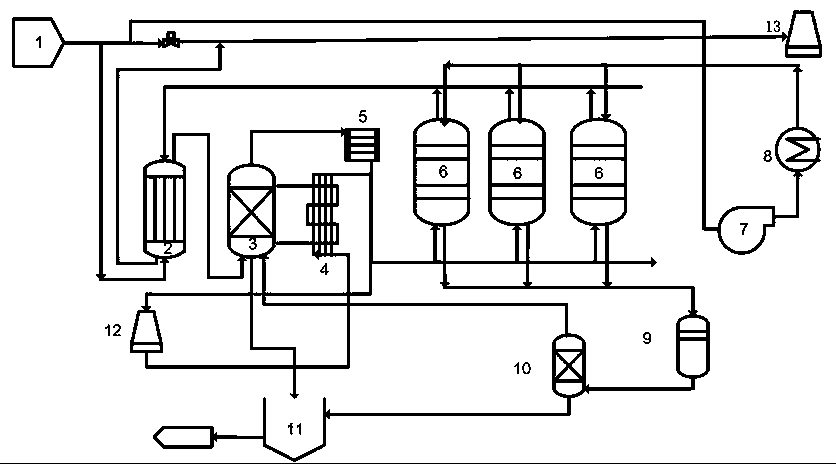

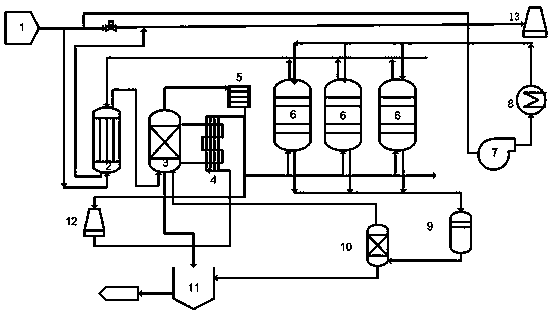

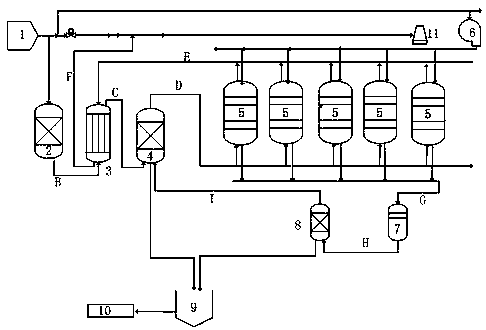

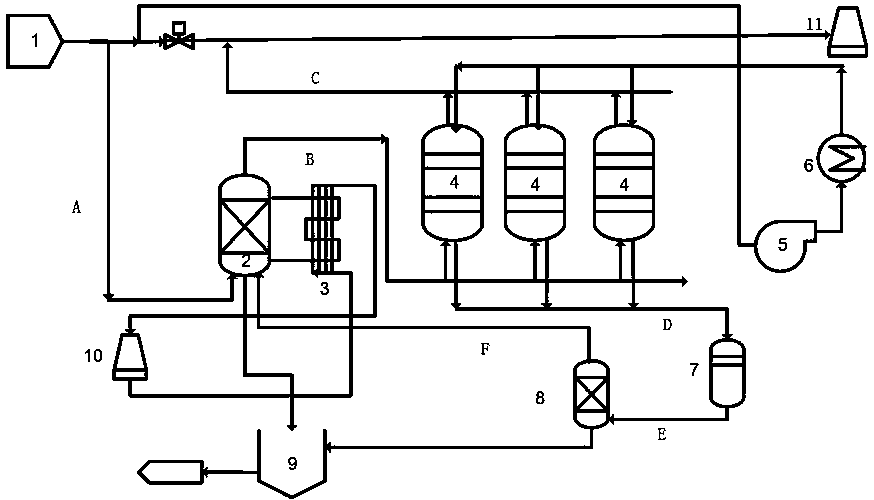

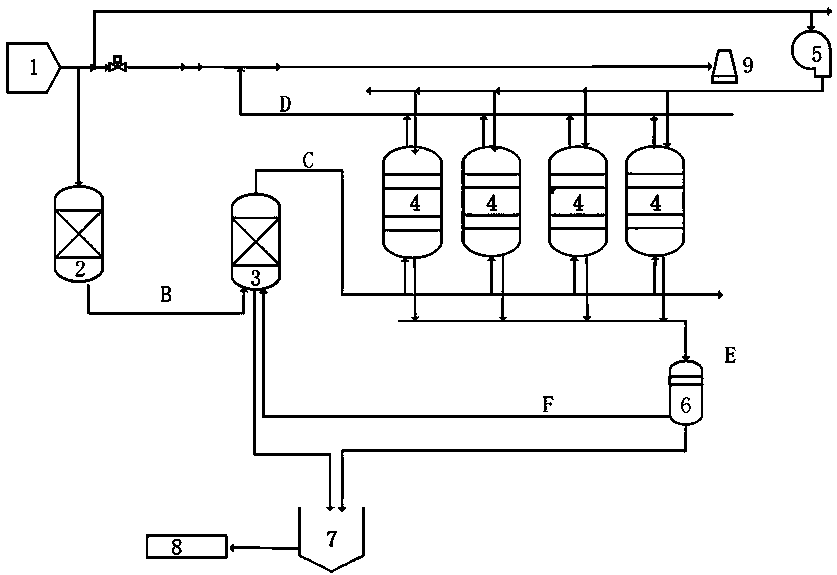

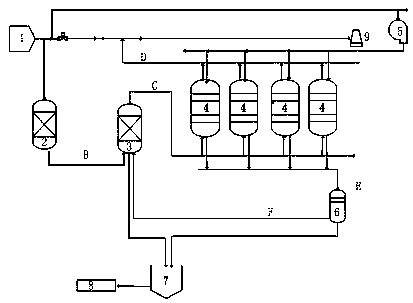

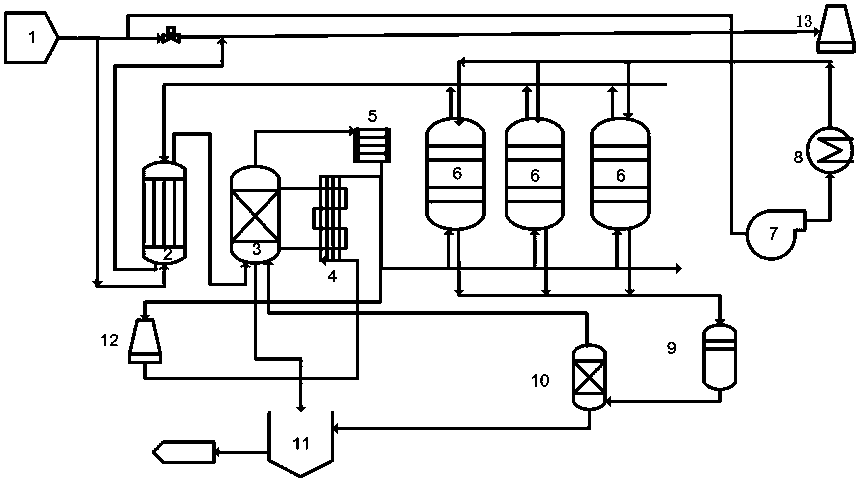

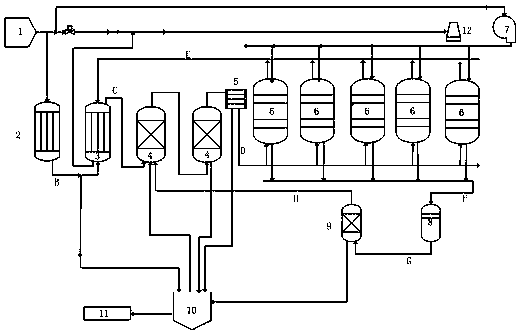

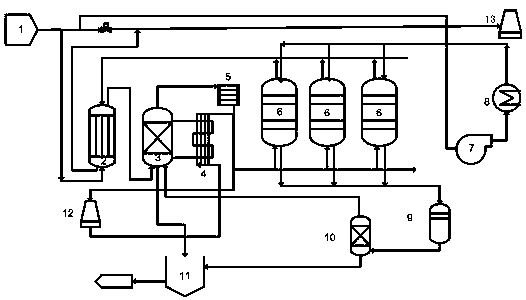

Desulfurization and denitrification method for coke oven flue gas

PendingCN109806742AGuaranteed uptimeLow costLighting and heating apparatusUsing liquid separation agentCooling towerSorbent

The invention relates to a desulfurization and denitrification method for coke oven flue gas, and aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the coke oven flue gas. The method involved in the invention is characterized by comprising the following steps: removing sulfide from coke oven gas or blast furnace gas to be burned in a coke oven before the coke oven gas or blast furnace gas enters the coke oven, and then enabling the coke oven gas or blast furnace gas to burn; recording the coke oven flue gas containing the sulfide and nitrogen oxides educed from a coke oven flue channel as logistics A, wherein the temperature of the logistics A is 120-320 DEG C; enabling the logistics A to enter a heat exchanger and form a logistics B after flue gas heat exchange with a chimney, wherein the temperature of the logistics B is 100-180 DEG C; enabling the logistics B to enter a cooling tower and form a logistics C after spraying, cooling and dust removal, wherein the temperature of the logistics C is 30-100 DEG C; enabling the logistics C to enter an adsorption tower containing a microcrystalline adsorbent and form a logistics D after adsorption of the sulfide and the nitrogen oxides; and enabling the logistics D to enter the chimney so as to be discharged after heat exchange with the logistics A and warming. Therefore, the above technical problems are well solved. The method can be applied to the industrial production of desulfurization and denitrification of the coke oven flue gas.

Owner:湖北申昙环保新材料有限公司

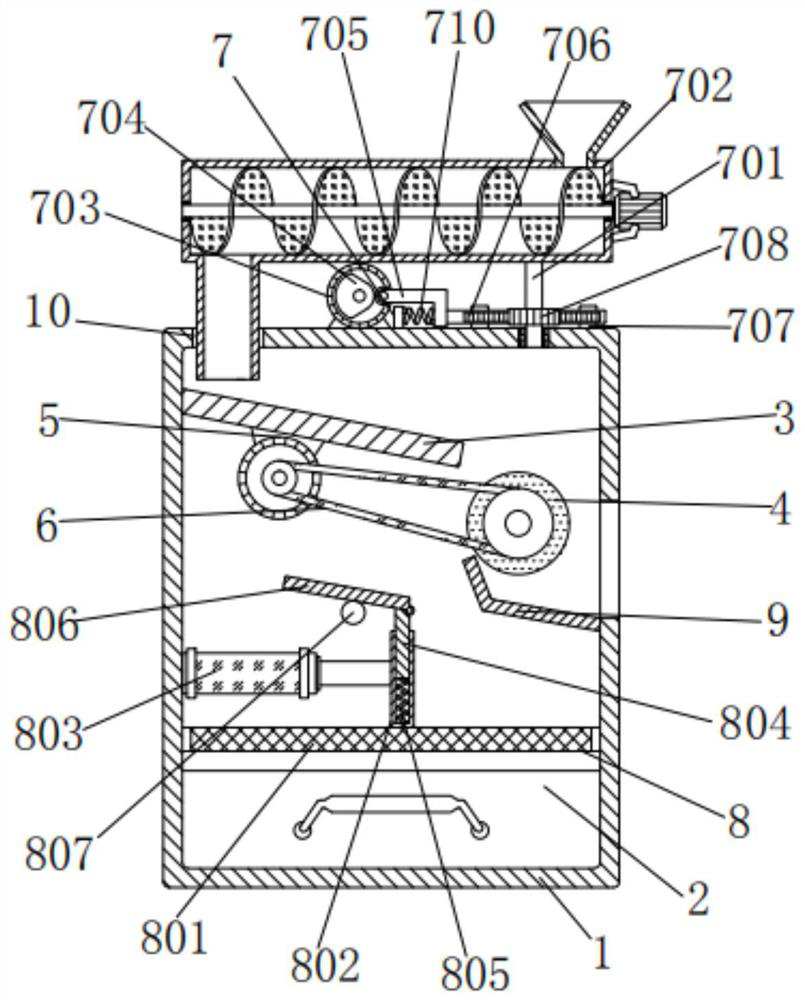

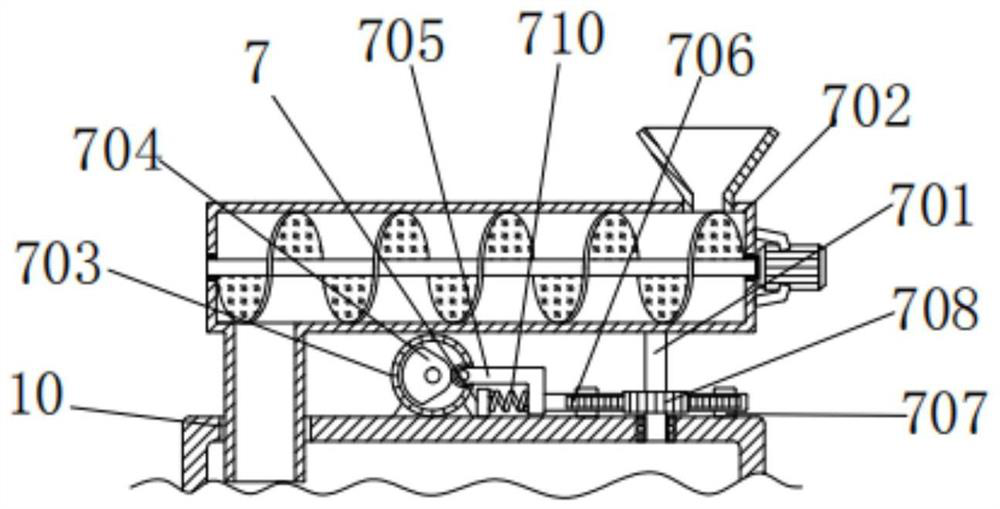

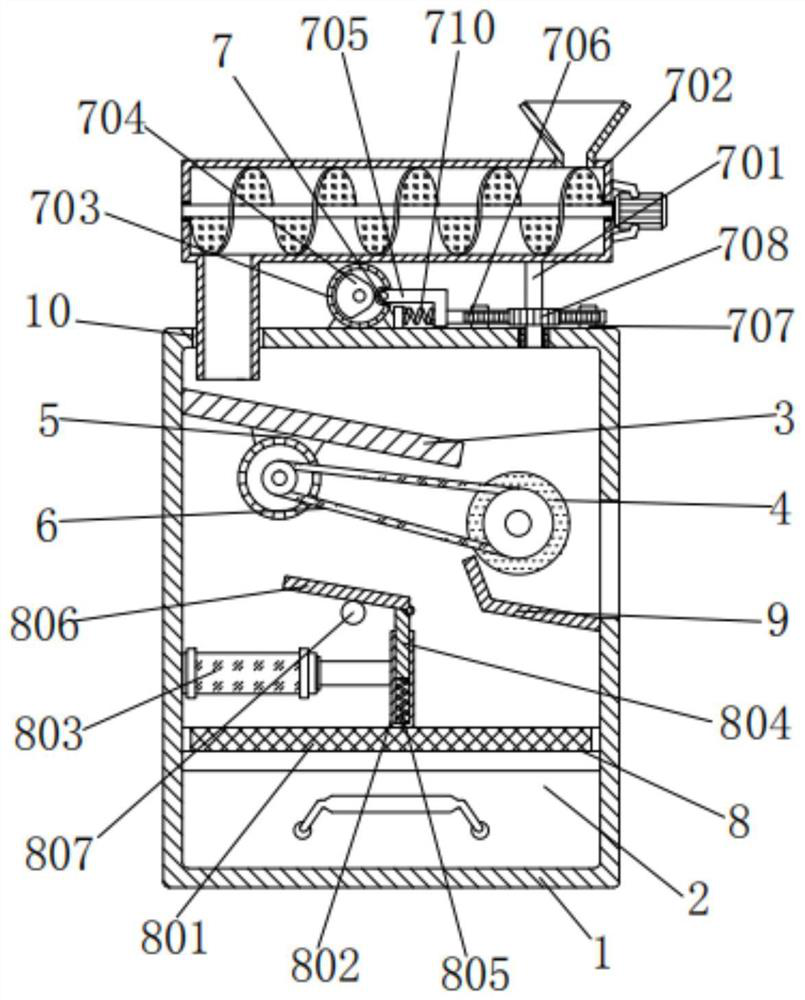

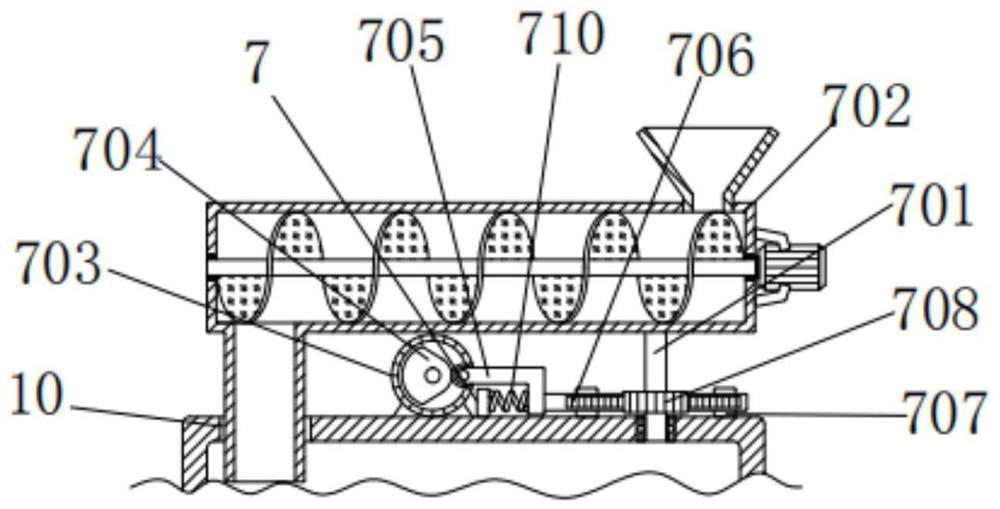

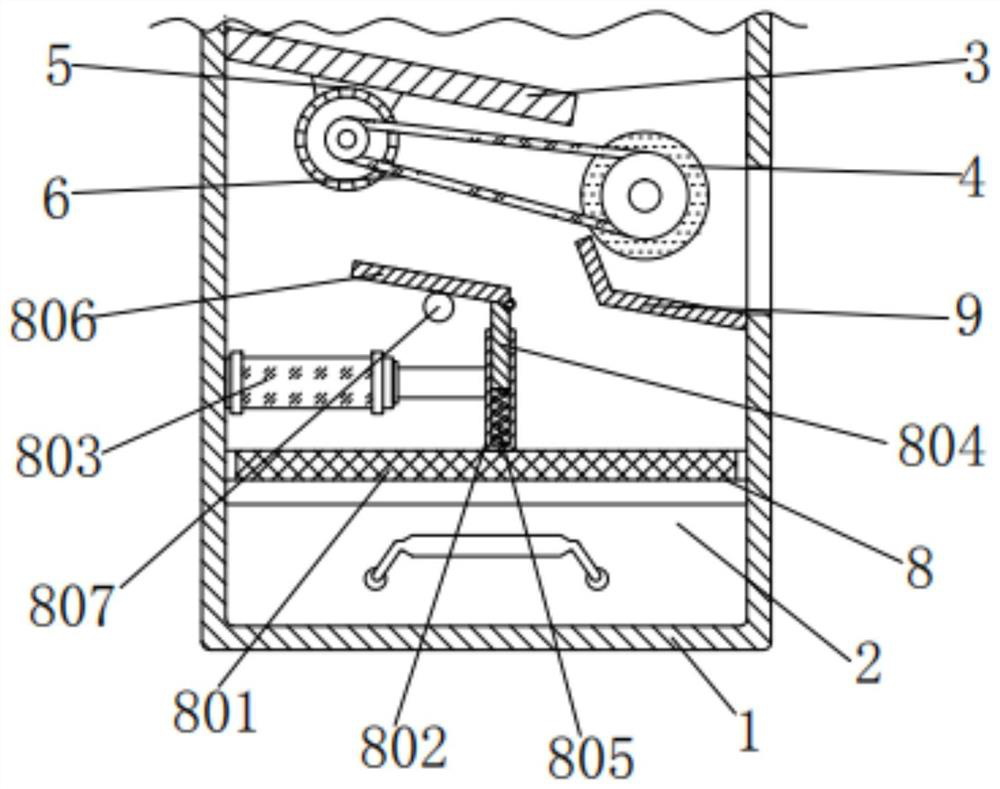

Multifunctional construction waste treatment equipment

InactiveCN111701979AImprove uniformityImprove adsorption accuracyConstruction waste recoverySolid waste disposalElectric machineryRefuse Disposals

The invention discloses multifunctional construction waste treatment equipment. The equipment comprises a box, an opening is machined in the left side of the top of the box, a first motor is fixedly connected to the bottom of an inclined plate, the first motor is rotationally connected with a front preset grooved wheel of a magnetic roller through a belt, and a discharging assembly is arranged atthe top of the box. According to the multifunctional construction waste treatment equipment, through meshing connection between a gear and a rack and clearance fit between the rack and a lantern ring,the rack can slide left and right in a reciprocating mode under the rotation of a cam and the action of a first spring, and the gear can rotate and drive an auger conveyor to swing in a reciprocatingmode through a vertical rod so that materials can uniformly fall onto the inclined plate, and the uniformity of adsorbing iron-containing substances in construction waste by the magnetic roller is improved; the materials can be guided, so that the materials are prevented from splashing to other places; and then the continuous crushing effect on the materials is achieved so that the materials canbe crushed into fine materials to be collected, and the convenience of subsequent treatment is greatly improved.

Owner:田莉华

Low-temperature desulfurization and denitrification method for sintering flue gas

PendingCN109499313AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasSulfide

The invention discloses a low-temperature desulfurization and denitrification method for sintering flue gas, relates to a desulfurization and denitrification method for the sintering flue gas, and mainly aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the sintering flue gas. The desulfurization anddenitrification method is characterized by removing nitrogen oxide and sulfide in the sintering flue gas by adopting an adsorption method, and performing salt-making treatment on the nitrogen oxide and sulfide in regenerated flue gas, so that the above problems are solved well. The desulfurization and denitrification method can be applied to the industrial production of desulfurization and denitrification of the sintering flue gas in iron and steel plants.

Owner:湖北申昙环保新材料有限公司

Sintering smoke gas low-temperature desulfurization and denitrification method

InactiveCN109513346AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationNitric oxideNitrogen oxide

The invention relates to a sintering smoke gas low-temperature desulfurization and denitrification method, which mainly solves the problems of high operation cost and secondary pollution generation ofthe existing sintering smoke gas desulfurization and denitrification. The method has the technical scheme that a microcrystalline material adsorption method is used for eliminating nitric oxides andsulfides in the sintering smoke gas; the nitric oxides and sulfides in the regenerated smoke gas are oxidized to be used as resources. The problems are well solved. The method can be used in the industrial production of steel and iron factory smoke gas desulfurization and denitrification.

Owner:山东洲蓝环保科技有限公司

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453660AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationNitrogen oxideNitric oxide

The invention relates to a low-temperature desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the low-temperature desulfurization and denitrification method of the boiler smoke, nitric oxide and sulfide in the boiler smoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to salt manufacturing treatment. According to the technical scheme, by adopting the low-temperature desulfurization and denitrification method of the boiler smoke, the problems are well solved, and the method can be used for industrial production of desulfurization and denitrification of the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

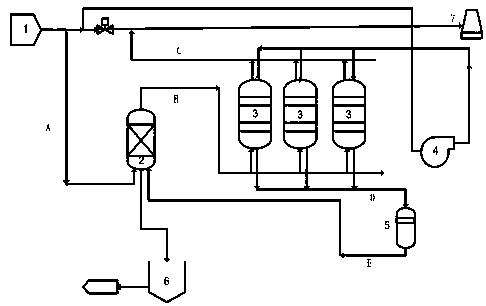

Low-temperature desulfurization and denitrification method for coke oven flue gas

InactiveCN109464911AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention relates to a low-temperature desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The low-temperature desulfurization and denitrification method disclosed by the invention adopts the technical scheme that the coke oven flue gas containing sulfide and nitrogen oxide, induced from a coke oven flue, enters a denitrification tower containing a denitrification catalyst; the nitrogen oxide and the sulfide in the coke oven flue gas are removed according to a catalytic reduction and adsorption method; the nitrogen oxide and the sulfide in regenerated flue gas are subjected to salt preparation treatment, the problems are better solved; the method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method for coke oven flue gas

InactiveCN109464910AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationFlue gasCoke oven

The invention relates to a low-temperature desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The low-temperature desulfurization and denitrification method disclosed by the invention adopts the technical scheme that nitrogen oxide and sulfide in the coke oven flue gas are removed according to a microcrystalline material adsorption method; nitrogen oxide and sulfide in regenerated flue gas are oxidized and recycled, the technical problems are better solved. The method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Pelletizing smoke gas low-temperature desulfurization and denitrification method

InactiveCN109513341AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationNitric oxideSulfide

The invention relates to a pelletizing smoke gas desulfurization and denitrification method, which mainly solves the problems of high operation cost and secondary pollution generation of the existingpelletizing smoke gas desulfurization and denitrification. The method has the technical scheme that an adsorption method is used for eliminating nitric oxides and sulfides in pelletizing smoke gas; the nitric oxides and sulfides in the regenerated smoke gas are subjected to salt preparation treatment. The problems are well solved. The method can be used in the industrial production of steel and iron factory smoke gas desulfurization and denitrification.

Owner:山东洲蓝环保科技有限公司

Desulfurization and denitration method for boiler flue gas

PendingCN109499317AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasNitrogen oxide

The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solving the problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting the technical scheme that nitrogen oxides and sulfides are removed from the boiler flue gas by an adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to salt making treatment, the above problem is better solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Method for desulfurization and denitration of sintering flue gas

PendingCN109550393AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationFlue gasNitrogen oxide

The invention relates to a method for desulfurization and denitration of sintering flue gas. The problems that an existing technique for desulfurization and denitration of sintering flue gas has highoperation cost and secondary pollution are solved mainly. According to the technical scheme, an adsorption method is adopted to remove nitrogen oxides and sulfides in the sintering flue gas, and saltmanufacturing treatment is performed on nitrogen oxides and sulfides in regenerated flue gas, so that the problems are solved well; and the method can be applied to industrial production of desulfurization and denitration of flue gas in steel plants.

Owner:马广伟

Desulfurization and denitrification method for pelletizing flue gas

PendingCN109499307AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasNitrogen oxide

The invention relates to a desulfurization and denitrification method for pelletizing sintering flue gas, and mainly aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the pelletizing sintering flue gas. The method is characterized by removing nitrogen oxide and sulfide in the pelletizing sintering flue gas by adopting an adsorption method, and performing salt-making treatment on the nitrogen oxide and sulfide in regenerated flue gas, so that the above problems are solved well. The method can be applied to the industrial production of desulfurization and denitrification of flue gas in iron and steel plants.

Owner:湖北申昙环保新材料有限公司

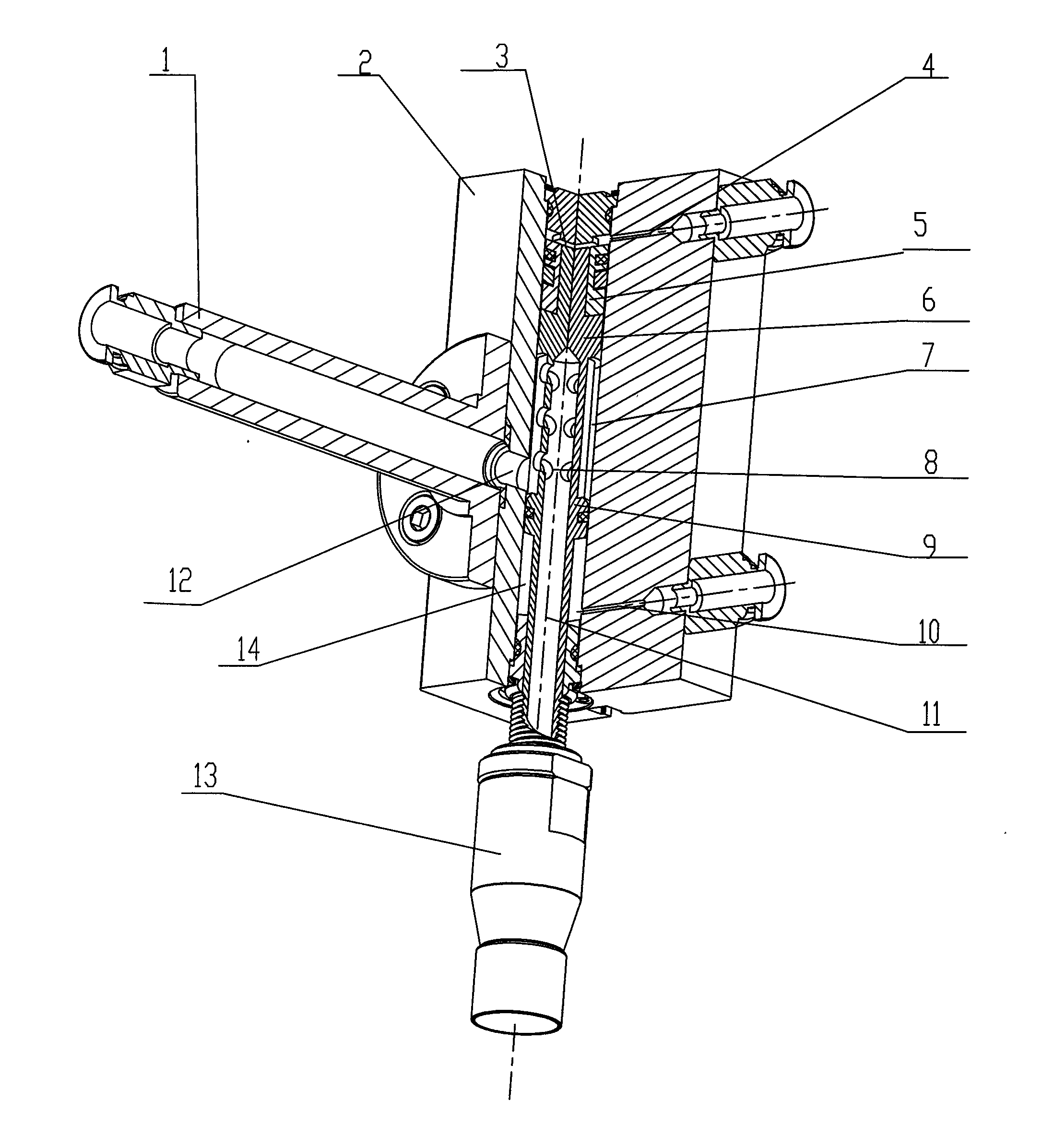

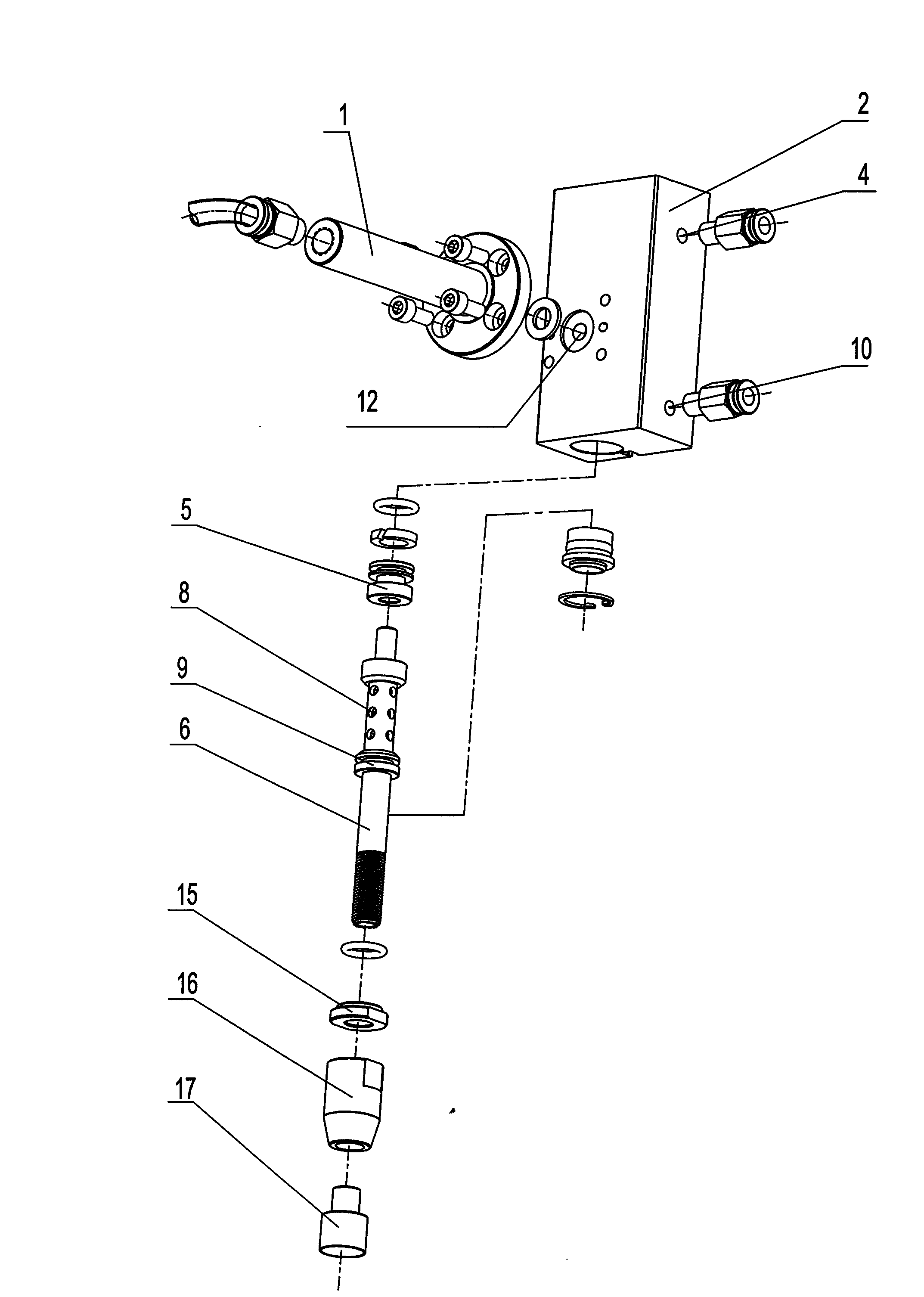

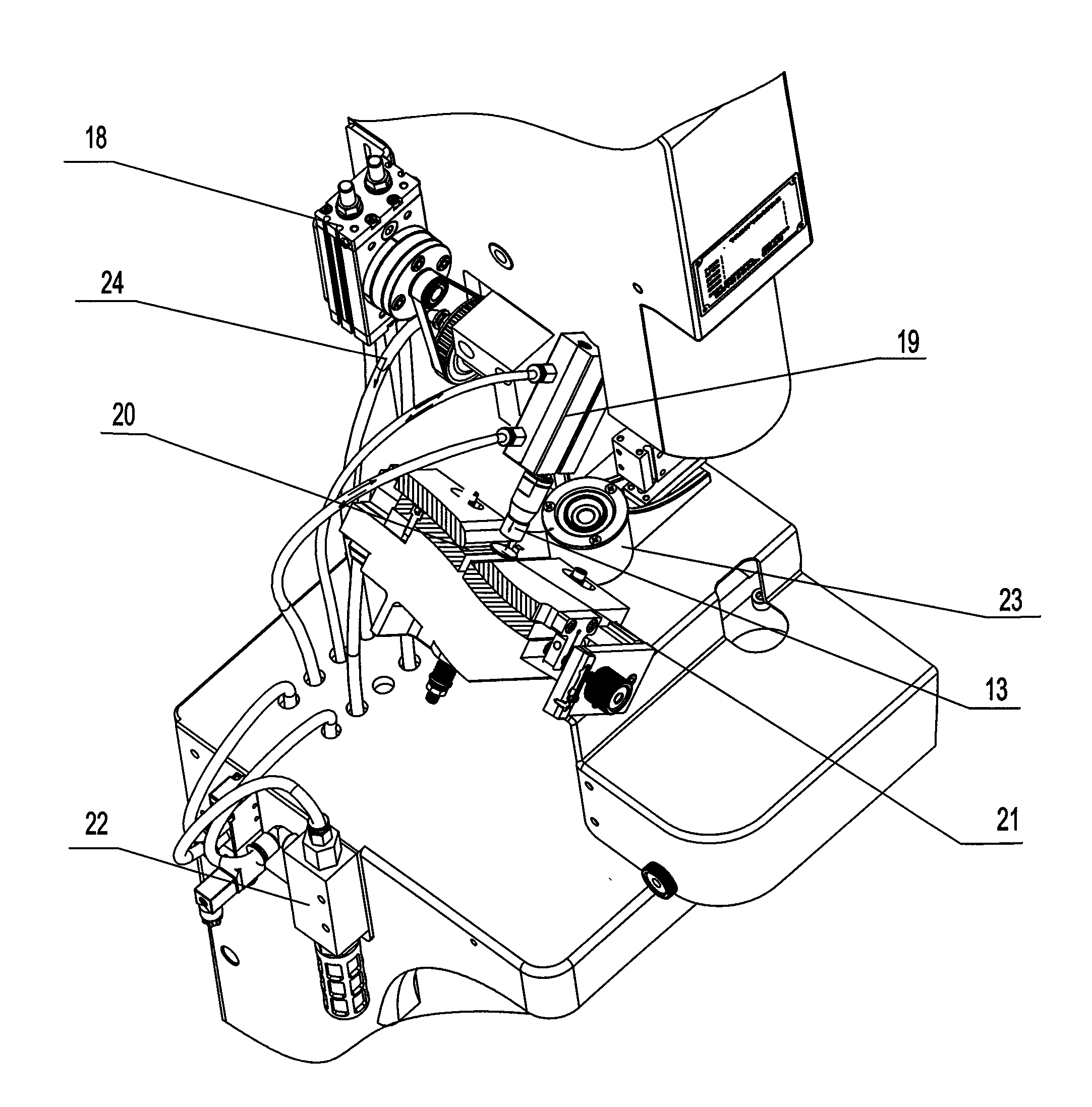

Built-in air suction cylinder

InactiveCN103009396AImprove adsorption accuracyReduce manufacturing costGripping headsEngineeringCylinder block

The invention relates to a cylinder, in particular to a built-in air suction cylinder with an air suction function. The built-in air suction cylinder comprises a cylinder body, a piston rod and a piston. The piston consists of an upper piston and a lower piston. The upper piston and the lower piston are arranged on the piston rod at a certain distance to enable the chamber of the cylinder to form two piston chambers. The middle section of the chamber of the cylinder forms an air inlet chamber. An air chamber air outlet is arranged in the cylinder body corresponding to the air inlet chamber. An axial air flow passage is arranged in the piston rod. A radial air outlet is arranged in the body of the piston rod at a position where the air inlet chamber is arranged. The radial air outlet is connected with the outlet end of the axial air flow passage. The inlet end of the axial air flow passage stretches out of the external end of the piston rod. The invention aims at designing the built-in air suction cylinder with the air suction function, a small size and a small structure. Compared with the prior art, the built-in air suction cylinder provided by the invention has the advantages that the cylinder has dual functions of a manipulator and an adsorption mechanism, the production cost is low, the workpiece adsorption accuracy is high, the working response time is short, convenience is provided for the reasonable layout of automatic corollary equipment and the space is saved.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

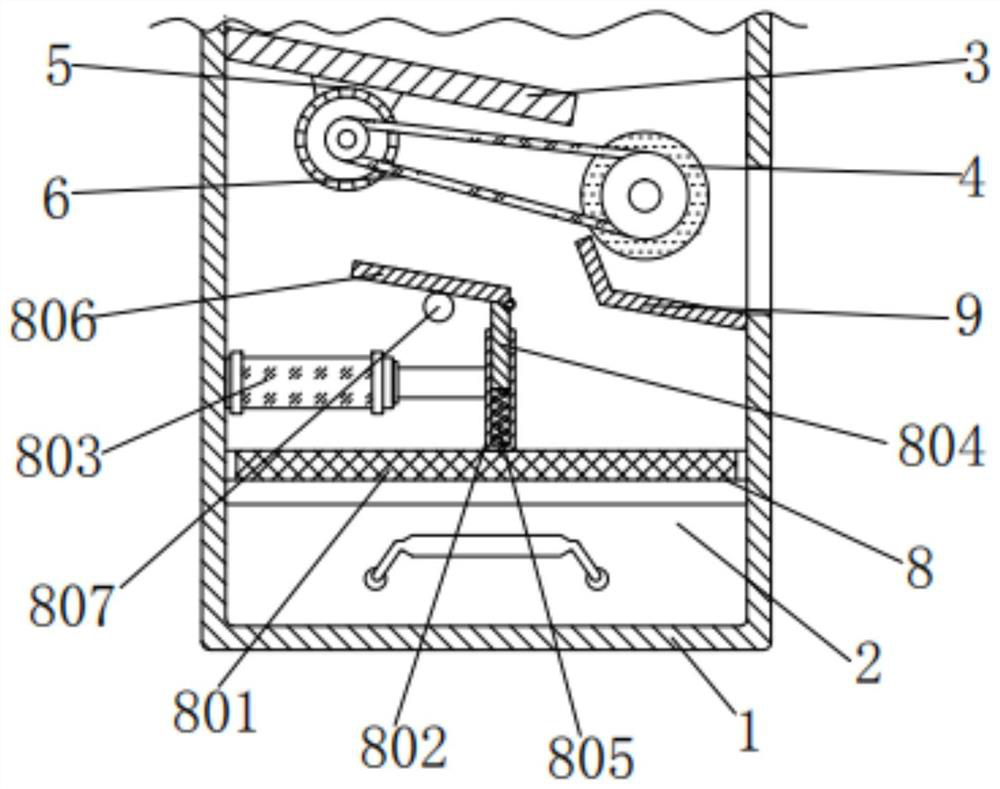

Anti-blocking type multifunctional construction waste treatment equipment

InactiveCN112045899AAvoid cloggingImprove filtration efficiencySievingScreeningWaste treatmentRefuse Disposals

The invention belongs to the technical field of construction waste treatment equipment, and particularly relates to anti-blocking multifunctional construction waste treatment equipment. The waste treatment equipment comprises a box body, wherein a discharging assembly is arranged at the top of the box body, a compression assembly is arranged at the lower part in the box body, the compression assembly comprises a filter screen, a top plate, an air cylinder, a vertical plate, a second spring, a baffle and a round rod, the filter screen is fixedly connected to the lower portion of the inner wallof the box body, the filter screen is round, a plurality of rotationally-connected connecting shafts are arranged at the bottom of the filter screen, torsion springs connected with the connecting shafts are arranged between the connecting shafts and the filter screen, knocking rods which are fixedly connected and used for vibrating and knocking the filter screen are arranged on one sides of the connecting shafts, transmission rods which are fixedly connected are arranged on the connecting shafts in the direction perpendicular to the knocking rods, and a shifting rod which can rotate and is used for shifting the transmission rods to rotate is arranged at the bottom of the filter screen to vibrate the surface of the filter screen. According to the anti-blocking multifunctional construction waste treatment equipment, the filter screen is effectively prevented from being blocked in the using process, and the filtering efficiency of the filter screen is improved.

Owner:田莉华

Low-temperature comprehensive desulfurization and denitration method for boiler flue gas

PendingCN109499310ALow costGuaranteed uptimeGas treatmentUsing liquid separation agentBoiler furnaceFlue gas

Low-temperature comprehensive desulfurization and denitration method for boiler flue gas. The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solving the problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting thetechnical scheme that coke-oven gas or blast furnace gas entering a boiler furnace for combustion is subjected to sulfide removal prior to entering a coke oven and then is burnt, nitrogen oxides andsulfides are removed from the boiler flue gas by an adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to salt making treatment, the above problem isbetter solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453649AGuaranteed uptimeLow costGas treatmentDispersed particle separationSulfideNitrogen oxide

The invention relates to a desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the desulfurization and denitrification method of the boiler smoke, for coke oven gas or blast furnace gas which enters a boiler for burning, before the coke oven gas or the blast furnace gas enters the boiler, sulfide is removed at first, then burning is conducted, nitric oxide and the sulfide in the boiler smoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to salt manufacturing treatment. According to the technical scheme, by adopting the desulfurization and denitrification method of the boiler smoke, the problems are well solved, and the method can be used for industrial production of desulfurization and denitrification of the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453650AGuaranteed uptimeLow costGas treatmentDispersed particle separationResource utilizationNitric oxide

The invention relates to a desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the desulfurization and denitrification method of the boiler smoke, micro-crystal materials are adopted, for coke oven gas or blast furnace gas which enters a boiler for burning, before the coke oven gas or the blast furnace gas enters the boiler, sulfide is removed at first, then burning is conducted, nitric oxide and the sulfide in the boilersmoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to oxidization for resource utilization. According to the technical scheme, by adoptingthe desulfurization and denitrification method of the boiler smoke, the technical problems are well solved, and the method can be used for industrial production of desulfurization and denitrificationof the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

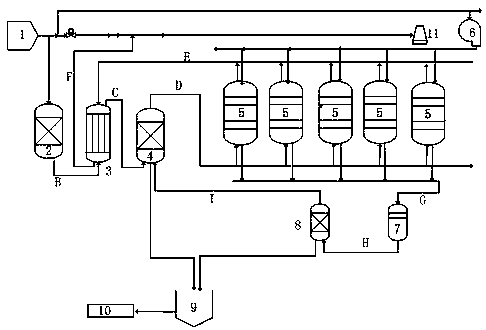

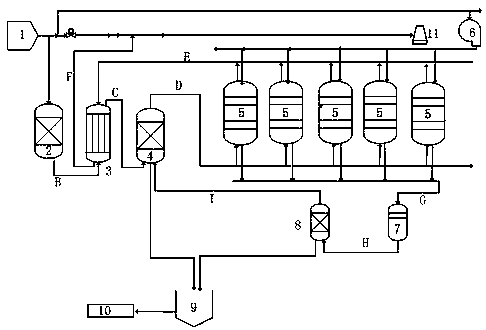

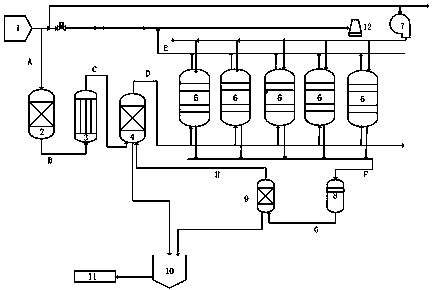

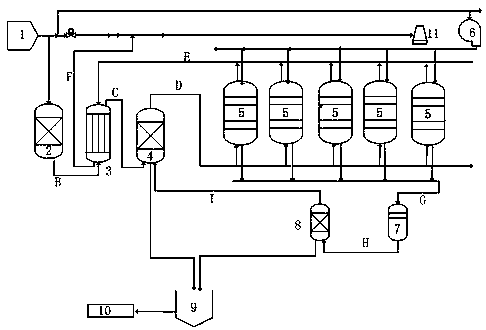

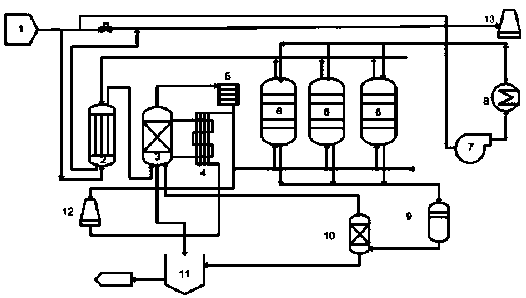

Low temperature desulfurization and denitrification method of coke oven flue gas

InactiveCN109731463AExtended service lifeImprove adsorption capacityDispersed particle separationCooling towerSorbent

The invention relates to a desulfurization and denitrification method of coke oven flue gas and mainly solves the problem that existing desulfurization and denitrification operation for coke oven fluegas has high cost and causes secondary pollution. According to the technical scheme, the method herein includes: allowing coke oven flue gas to enter a denitrifying column with a denitrifying catalyst, allowing the flue gas to enter a cooling column after catalytic reduction, cooling by spraying, removing dust, allowing the flue gas to enter an adsorbing column with a microcrystalline adsorbent to adsorb sulfides and oxygen nitrides, and discharging the flue gas via a chimney; subjecting the oxygen nitrides and sulfides in the regenerated flue gas to salt manufacturing. The above problem is well solved by using the method; the method is suitable for the industrial production of desulfurization and denitrification of coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitration method for boiler flue gas

PendingCN109499318AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentProcess engineeringEngineering

Low-temperature desulfurization and denitration method for boiler flue gas. The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solvingthe problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting the technical scheme that nitrogen oxides and sulfides are removed from the boiler flue gas by a microcrystalline material adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to oxidation for resource-converting utilization, the above technical problem is better solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for pelletizing exhaust gas

InactiveCN109513350AExtended service lifeImprove adsorption capacityGas treatmentLighting and heating apparatusNitrogen oxideEngineering

The invention relates to a desulfurization and denitrification method for pelletizing exhaust gas. The method is mainly adopted for solving the problems of high running cost and secondary pollution ofpresent desulfurization and denitrification for pelletizing exhaust gas. According to the invention, the technical scheme of adopting an absorbing method for removing nitric oxide and sulfide from pelletizing exhaust gas and then performing salt-production treatment on nitric oxide and sulfide in the regenerated exhaust gas is adopted for solving the problems. The method can be applied to industrial production of exhaust gas desulfurization and denitrification in steelworks.

Owner:山东洲蓝环保科技有限公司

Low-temperature desulfurization and denitrification method for coke oven flue gas

PendingCN109806741AExtended service lifeImprove adsorption capacityLighting and heating apparatusUsing liquid separation agentResource utilizationSulfide

The invention provides a low-temperature desulfurization and denitrification method for coke oven flue gas, relates to the desulfurization and denitrification method for the coke oven flue gas, and aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the coke oven flue gas. The method involved in the invention is characterized in that a microcrystalline material adsorption method is adopted to remove sulfide from coke oven gas or blast furnace gas to be burned in a coke oven before the coke oven gasor blast furnace gas enters the coke oven, and then the coke oven gas or blast furnace gas burns; an adsorption method is then used to remove nitrogen oxides and the sulfide from the coke oven flue gas; and oxidation is performed on the nitrogen oxides and the sulfide in the regenerated flue gas to realize resource utilization. Therefore, the above technical problems are well solved. The method can be applied to the industrial production of desulfurization and denitrification of the coke oven flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for sintering exhaust gas

InactiveCN109513349AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationExhaust gasNitric oxide

Owner:山东洲蓝环保科技有限公司

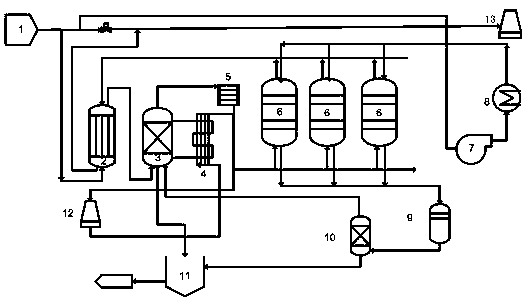

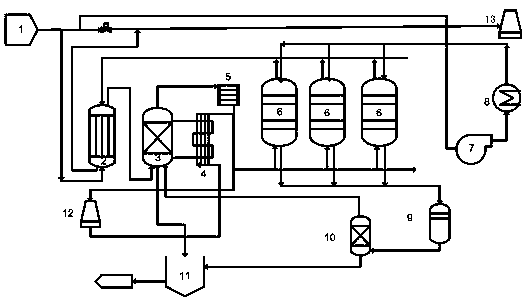

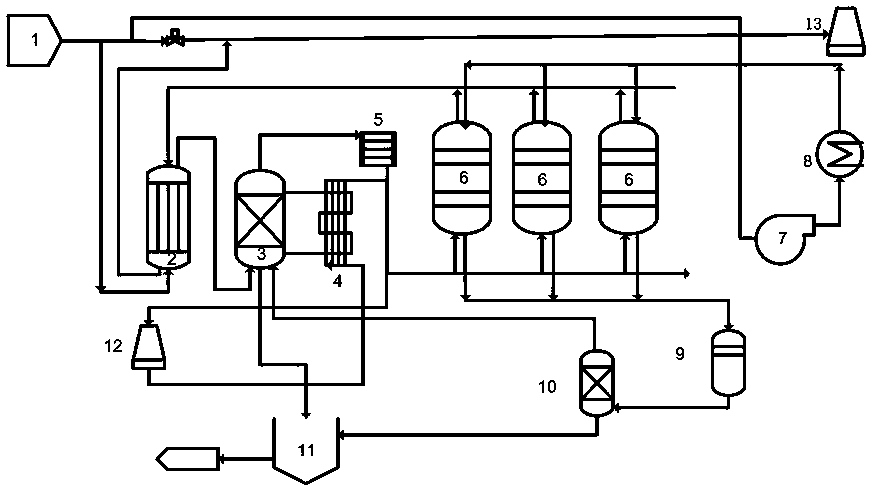

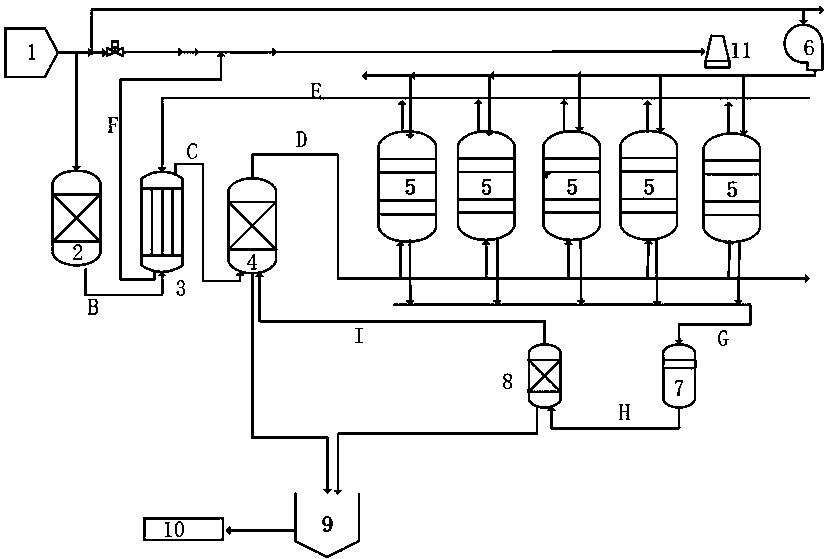

Desulfurization and denitrification method for coke oven flue gas

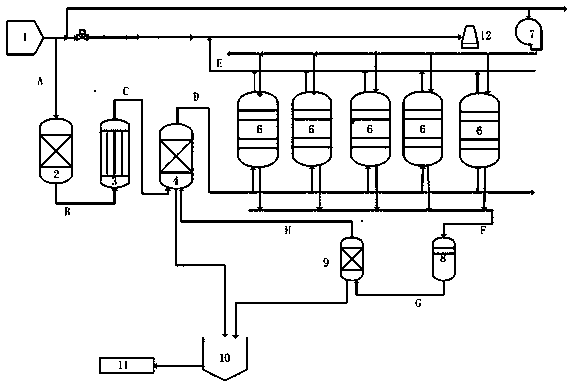

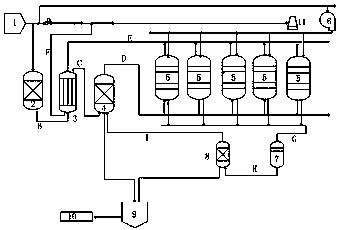

InactiveCN109464906AGuaranteed uptimeLow costGas treatmentDispersed particle separationCooling towerSorbent

The invention relates to a desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The desulfurization and denitrification method disclosed by the invention adopts the technical scheme that sulfide is removed before the coke oven gas or blast furnace gas enters a coke oven and then the coke oven gas is burnt; the method comprises the following steps: the coke oven gas containing the sulfide and nitrogen oxide,induced from the coke oven flue, is marked as a material flow A; the material flow A is subjected to waste heat utilization to produce steam, and the cooled flue gas forms a material flow B; the material flow B enters a heat exchanger, and is subjected to heat exchange with flue gas from a chimney to form a material flow C; the material flow C enters the cooling tower for cooling and dedusting toform a material flow D; the material flow D enters the adsorption tower containing a microcrystalline adsorbent for adsorbing the sulfide and the nitrogen oxide to form a material flow E; the material flow E is subjected to heat exchange with the material flow C, is heated up and then enters the chimney for emission, the problems are better solved; the method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

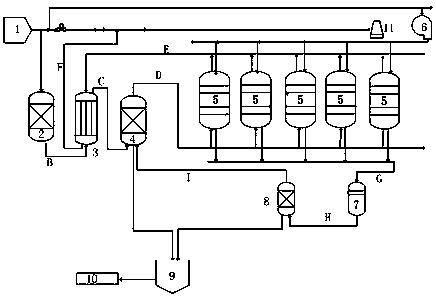

Low-temperature desulfurization and denitrification method of boiler smoke

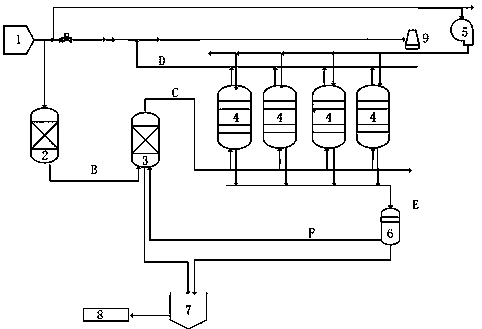

InactiveCN109453655AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationFlueNitric oxide

The invention relates to a low-temperature desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the low-temperature desulfurization and denitrification method of the boiler smoke, the boiler smoke which is led out of a boilerflue and contains sulfide and nitric oxide enters a denitrification tower containing a denitrification catalyst, enters a heat exchanger after being subjected to catalytic reduction, enters adsorptiontowers which contain micro-crystal adsorption agents after exchanging heat with smoke which goes to a chimney to enable the sulfide and the nitric oxide to be adsorbed, and then enters the chimney for discharge; nitric oxide and sulfide in regenerated smoke are subjected to salt manufacturing treatment. According to the technical scheme, by adopting the low-temperature desulfurization and denitrification method of the boiler smoke, the problems are well solved, and the method can be used for industrial production of desulfurization and denitrification of the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Boiler flue gas desulfurization and denitrification method

InactiveCN109464903AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationNitric oxidePollution

The invention relates to a boiler flue gas desulfurization and denitrification method and mainly aims to solve the problems that conventional boiler flue gas desulfurization and denitrification operation cost is high and secondary pollution can be caused. By adopting the technical scheme that before a coke oven gas or a blast furnace gas is fed into a boiler, sulfide is firstly removed from the coke oven gas or the blast furnace gas which is combusted in the boiler, nitric oxides and sulfide in a boiler gas are removed by using an adsorption method after combustion, and the nitric oxides and the sulfide in a regenerated flue gas are subjected to salt production treatment, the problems are well solved, and the method can be applied to industrial production of boiler flue gas desulfurizationand denitrification.

Owner:铜陵泰富特种材料有限公司 +1

Comprehensive desulfurization and denitration method for boiler flue gas

PendingCN109499320AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasNitrogen oxide

The invention relates to a desulfurization and denitration method for boiler flue gas. The method is mainly used for solving the problem that the existing boiler flue gas desulfurization and denitration are high in operating cost and secondary pollution is caused. According to the method, through adopting the technical scheme that nitrogen oxides and sulfides are removed from the boiler flue gas by an adsorption method, and the nitrogen oxides and the sulfides in the regenerated flue gas are subjected to salt making treatment, the above problem is better solved; the method can be applied to industrial production of desulfurization and denitration of the boiler flue gas.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method of boiler smoke

InactiveCN109453647AGuaranteed uptimeLow costGas treatmentDispersed particle separationResource utilizationSulfide

The invention relates to a desulfurization and denitrification method of boiler smoke. The problems that existing boiler smoke desulfurization and denitrification are high in running cost, and generate secondary pollution are mainly solved. According to the desulfurization and denitrification method of the boiler smoke, micro-crystal materials are adopted, for coke oven gas or blast furnace gas which enters a boiler for burning, before the coke oven gas or the blast furnace gas enters the boiler, sulfide is removed at first, then burning is conducted, nitric oxide and the sulfide in the boilersmoke are removed through an adsorption method, and nitric oxide and sulfide in regenerated smoke are subjected to oxidization for resource utilization. According to the technical scheme, by adoptingthe desulfurization and denitrification method of the boiler smoke, the technical problems are well solved, and the method can be used for industrial production of desulfurization and denitrificationof the boiler smoke.

Owner:铜陵泰富特种材料有限公司 +1

Low-temperature desulfurization and denitrification method of pelletizing flue gas

InactiveCN109529609AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle filtrationFlue gasNitric oxide

The invention relates to a desulfurization and denitrification of pelletizing flue gas, and mainly solves the problems of high running cost and secondary pollution of existing pelletizing flue gas desulfurization and denitrification. According to the method disclosed by the invention, through a technical scheme of removing nitric oxide and sulfide in the pelletizing flue gas by adopting an adsorption method and carrying out salt production treatment on the nitric oxide and the sulfide in regenerated flue gas, the problems can be well solved; the method can be used for industrial production offlue gas desulfurization and denitrification of a steel plant.

Owner:山东洲蓝环保科技有限公司

Desulfurization and denitrification method for sintering machine flue gas

PendingCN109499305AExtended service lifeImprove adsorption capacityGas treatmentUsing liquid separation agentFlue gasSulfide

The invention relates to a desulfurization and denitrification method for sintering flue gas, and mainly aims to solve the problems of high running cost and generation of secondary pollution in an existing desulfurization and denitrification process of the sintering flue gas. The method is characterized by removing nitrogen oxide and sulfide in the sintering flue gas by adopting an adsorption method, and performing salt-making treatment on the nitrogen oxide and sulfide in regenerated flue gas, so that the above problems are solved well. The method can be applied to the industrial production of desulfurization and denitrification of flue gas in iron and steel plants.

Owner:湖北申昙环保新材料有限公司

Low-temperature desulfurization and denitrification method for coke oven flue gas

InactiveCN109464912AExtended service lifeImprove adsorption capacityGas treatmentDispersed particle separationChemistryCoke oven gas

The invention relates to a low-temperature desulfurization and denitrification method for coke oven flue gas. The invention mainly aims at solving the problems of high operating cost and secondary pollution of conventional desulfurization and denitrification of the coke oven flue gas. The low-temperature desulfurization and denitrification method disclosed by the invention adopts the technical scheme that nitrogen oxide and sulfide in the coke oven flue gas are removed according to a microcrystalline material adsorption method; the nitrogen oxide and the sulfide in regenerated flue gas are oxidized and recycled, the technical problems are better solved. The method can be used in the industrial production of desulfurization and denitrification of the coking flue gas.

Owner:铜陵泰富特种材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com