Anti-blocking type multifunctional construction waste treatment equipment

A technology for construction waste and treatment equipment, applied in the direction of filter screen, grille, solid separation, etc., can solve the problems of affecting filtration efficiency, filter clogging, affecting treatment efficiency, etc., to improve treatment efficiency, prevent clogging, and improve filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

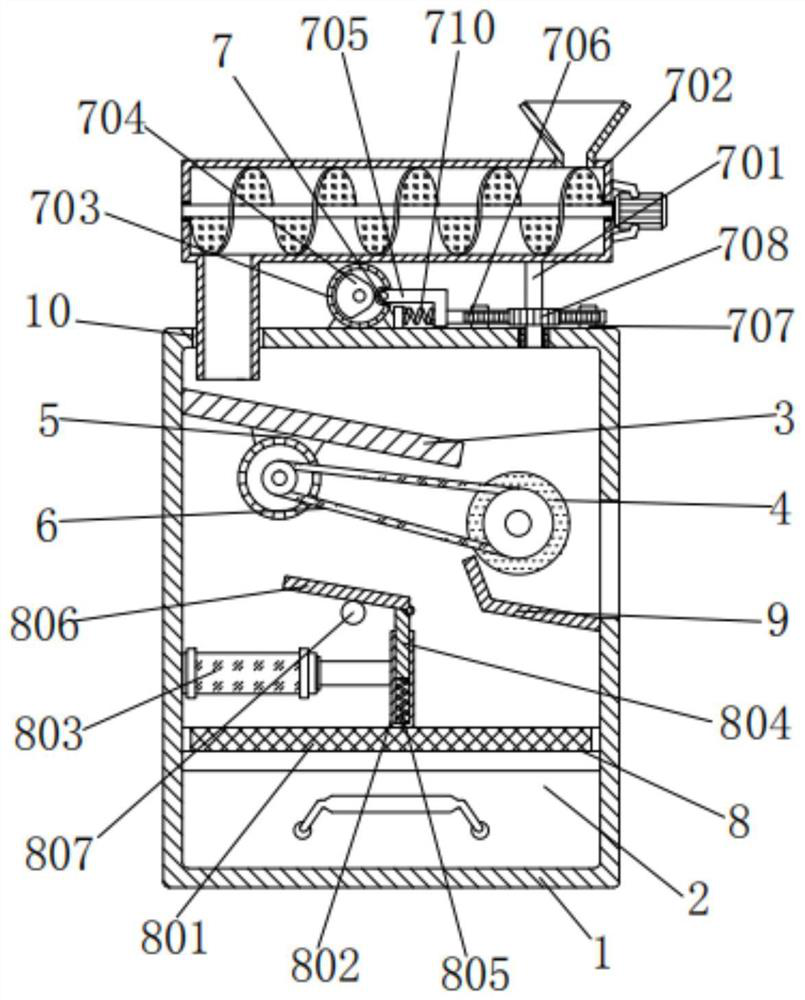

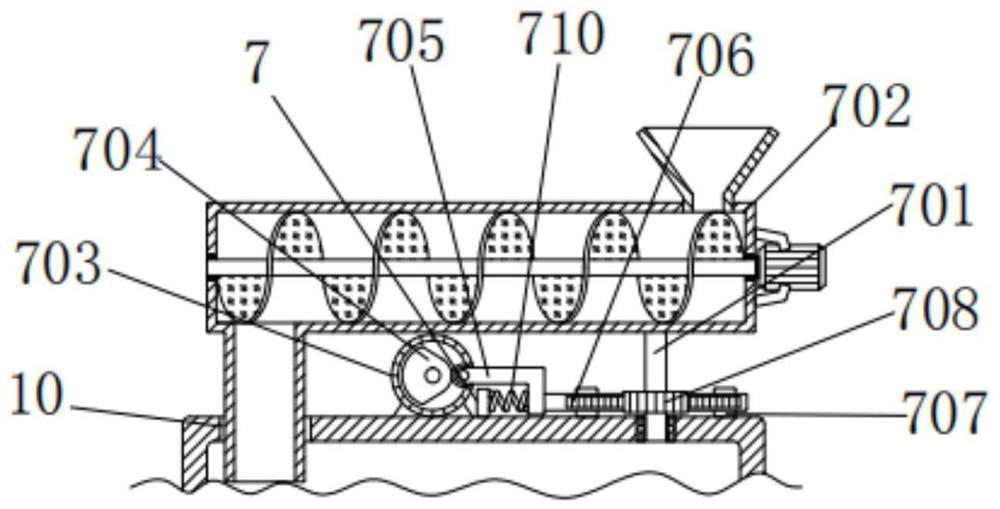

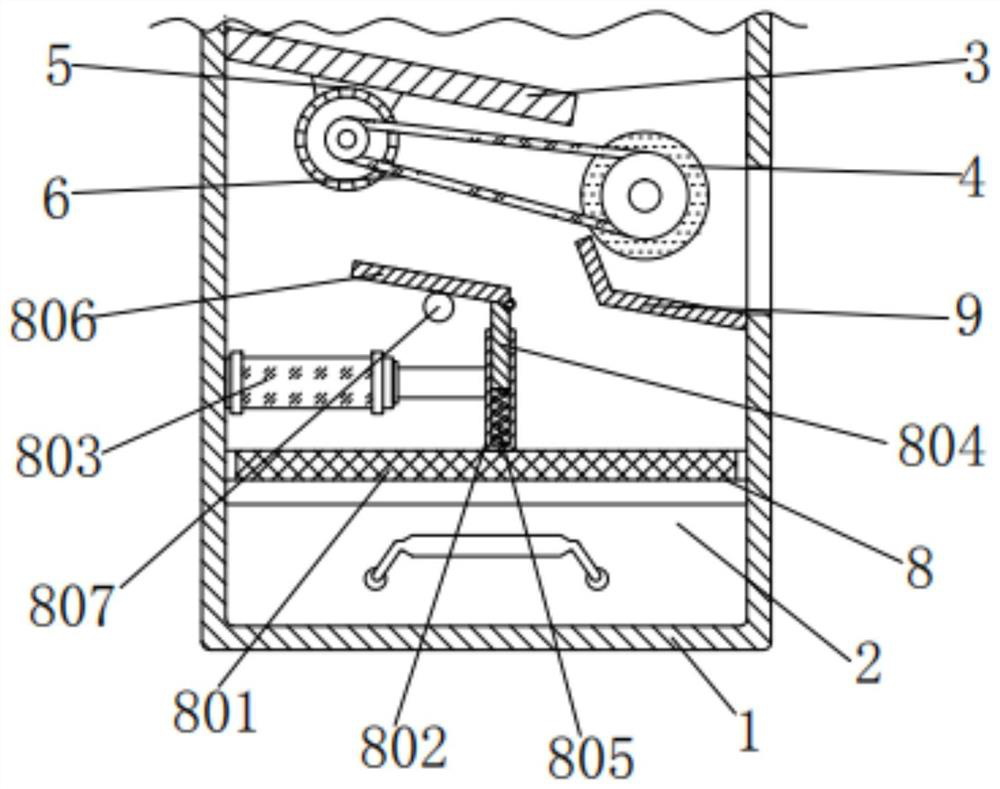

[0045]An anti-blocking multi-functional construction waste treatment equipment, comprising a box body 1, an opening 10 is processed on the top left side of the box body 1, a bracket 2 is placed on the bottom of the inner wall of the box body 1, and the left side of the inner wall of the box body 1 is fixed There is a sloping plate 3, and the right side of the inner wall of the box body 1 is connected with a magnetic roller 4. The positions of the swash plate 3 and the magnetic roller 4 correspond one by one. The bottom of the magnetic roller 4 is pressed against a scraper 9. The right end of the scraper 9 is connected The right end of the inner wall of the box body 1 is fixedly connected, the bottom of the swash plate 3 is fixedly connected with the first motor 5, and the front preset sheave of the first motor 5 and the magnetic roller 4 is rotationally connected by the belt 5, and the top of the box body 1 is provided with a lower Material assembly 7, blanking assembly 7 inclu...

Embodiment 2

[0047] As an option, see figure 1 , 3 , 6 and 7, 8, anti-clogging type multi-functional construction waste treatment equipment, the inner bottom of the box body 1 is provided with a compression assembly 8, the compression assembly 8 includes a filter screen 801, a top plate 802, a cylinder 803, a vertical plate 804, and a second spring 805, baffle plate 806 and round rod 807, the filter screen 801 is fixed on the bottom of the inner wall of the box body 1, the material of the filter screen 801 is stainless steel, its mesh number is ten mesh, the top of the filter screen 801 is pressed against a top plate 802, The left end of the top plate 802 is fixedly connected with the cylinder 803, the left end of the cylinder 803 is fixedly connected with the left end of the inner wall of the box body 1, the top gap of the top plate 802 is fitted with a riser 804, and the bottom of the riser 804 connects with the inner wall of the top plate 802 through the second spring 805. The bottom i...

Embodiment 3

[0053] An application of construction waste treatment equipment. When using the anti-blocking multifunctional construction waste treatment equipment, first connect the first motor 5 and the second motor 703 to an external power supply, and through the setting of the belt 6, the magnetic roller 4 Set clockwise, put the scraps of construction waste into the auger conveyor 2, through the axial rotation of the cam 704, through the setting of the first spring 710, the cam 704 and the roller 711 are pressed against each other, and through the rack 706 and the collar 707 The clearance fit makes the rack 706 reciprocatingly slide left and right, and then drives the auger conveyor 2 to reciprocate through the reciprocating rotation of the gear 708, so that the material can be evenly distributed on the inclined plate 3, and then guided to the left of the magnetic roller 4 through the inclined plate 3 side, and then adsorb the iron-containing substances in the material, and scrape them ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com