Built-in air suction cylinder

A cylinder and cylinder body technology, applied in the field of built-in suction cylinder, can solve the problems of fatigue of the joint between the leather tube and the cylinder, affecting the life of the adsorption mechanism of the manipulator, and the space occupied by the external suction cup assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

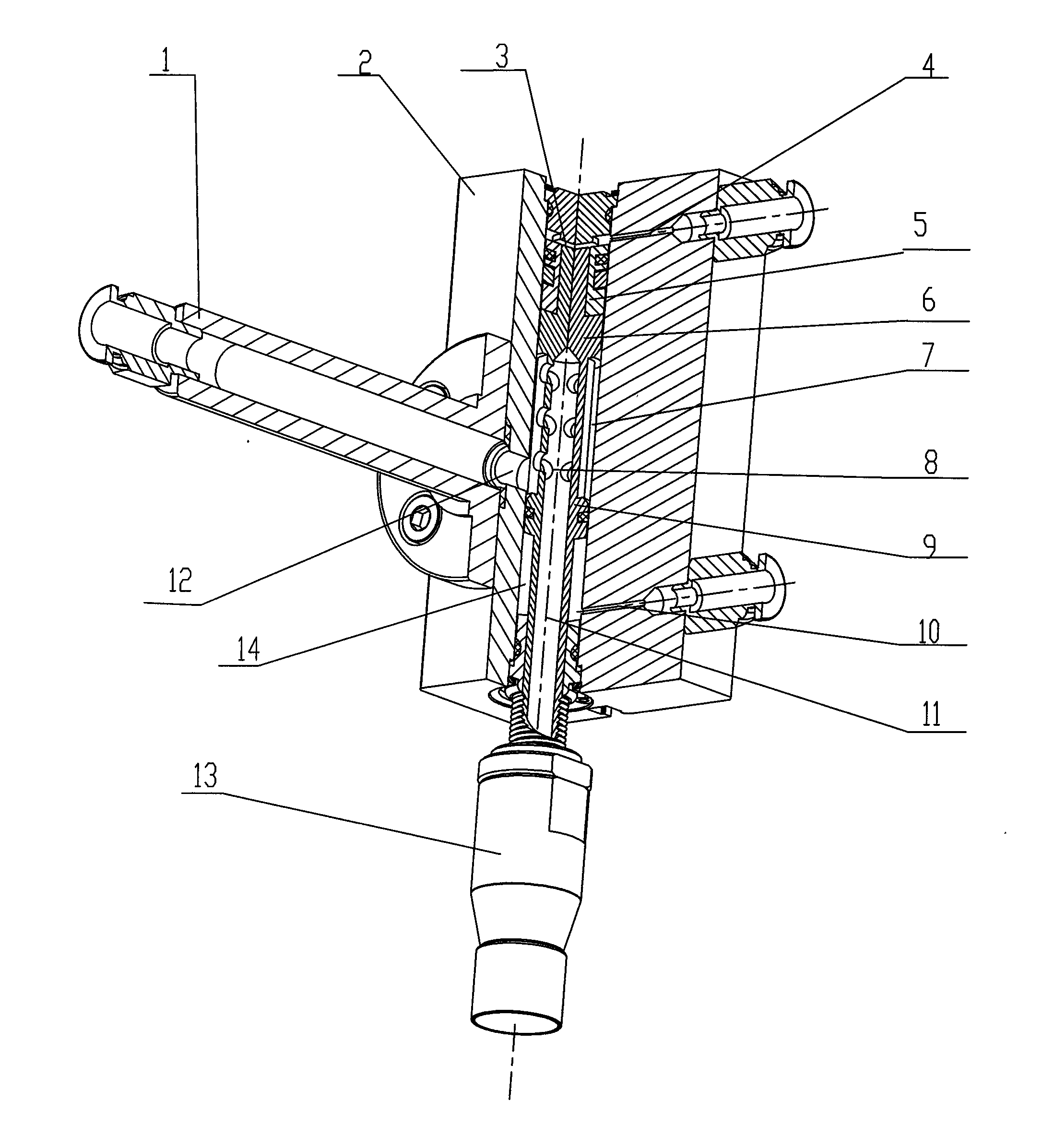

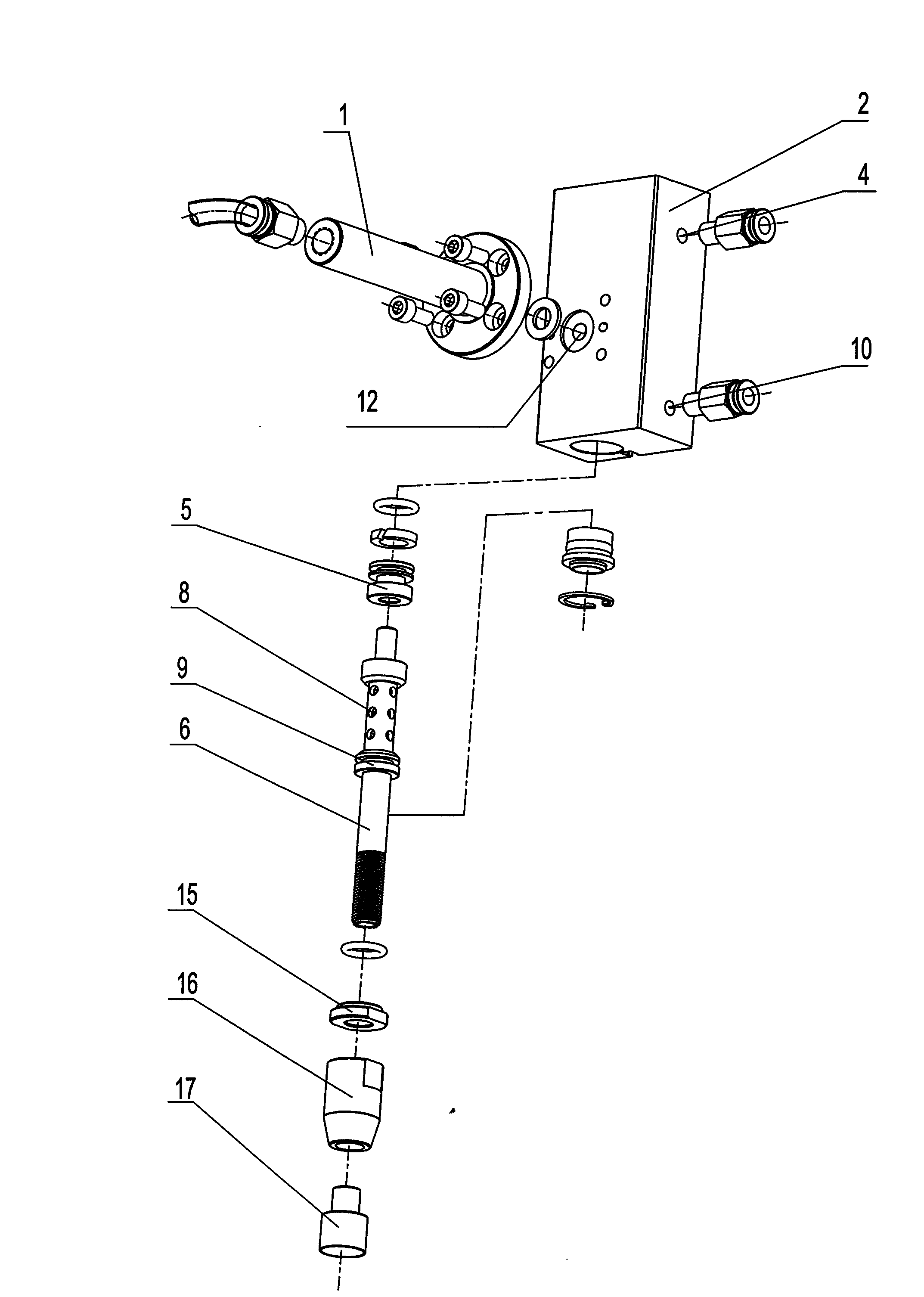

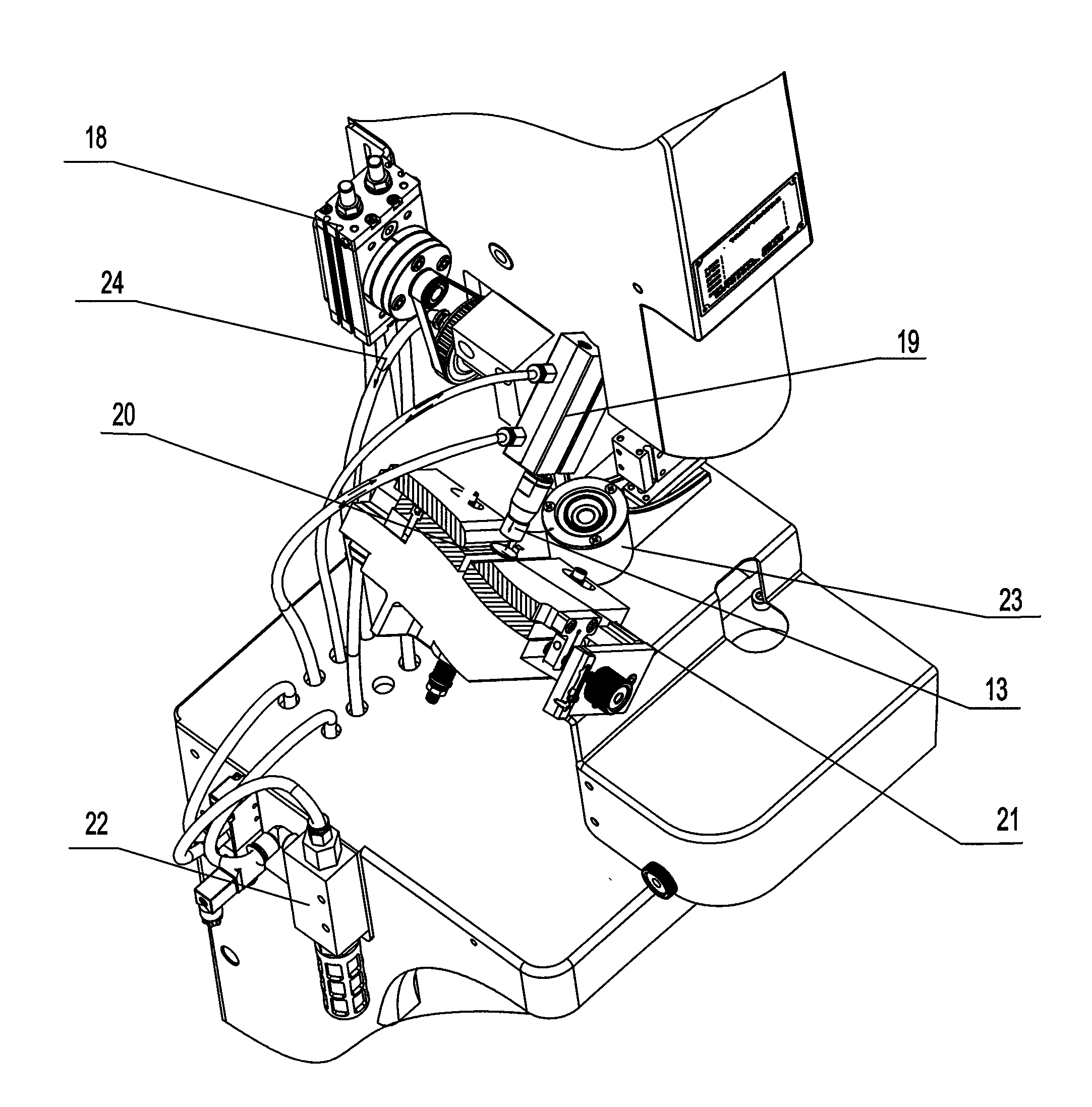

[0012] Such as figure 1 , figure 2 As shown, the present embodiment comprises cylinder body 2, piston rod 6, piston, and described piston is made up of upper and lower piston 5,9, and described upper piston 5 and described lower piston 9 are arranged on described piston rod with a certain distance apart. 6, the upper piston 5 and the upper end of the cylinder chamber in the cylinder body form an upper piston chamber 3, and the lower piston 9 and the lower end of the cylinder chamber in the cylinder body form a lower piston chamber 14, and the upper, The cylinder block corresponding to the lower piston cavity 3, 14 is respectively provided with an air intake passage 4, 10, and the cylinder cavity formed between the upper piston 5 and the lower piston 9 and the piston rod form an air intake chamber 7, which is connected to the intake air channel 7. The corresponding cylinder body of the air chamber 7 is provided with an air chamber outlet hole 12, and the piston rod 6 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com