Multifunctional construction waste treatment equipment

A technology for construction waste and processing equipment, applied in grain processing, construction waste recycling, cleaning methods and appliances, etc., can solve the problem of reducing the uniformity of adsorption of iron-containing substances by magnetic rollers, the inability of materials to fall evenly on the inclined plate, and the accuracy of adsorption Poor and other problems, to achieve the effect of improving adsorption accuracy, improving convenience, and facilitating finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

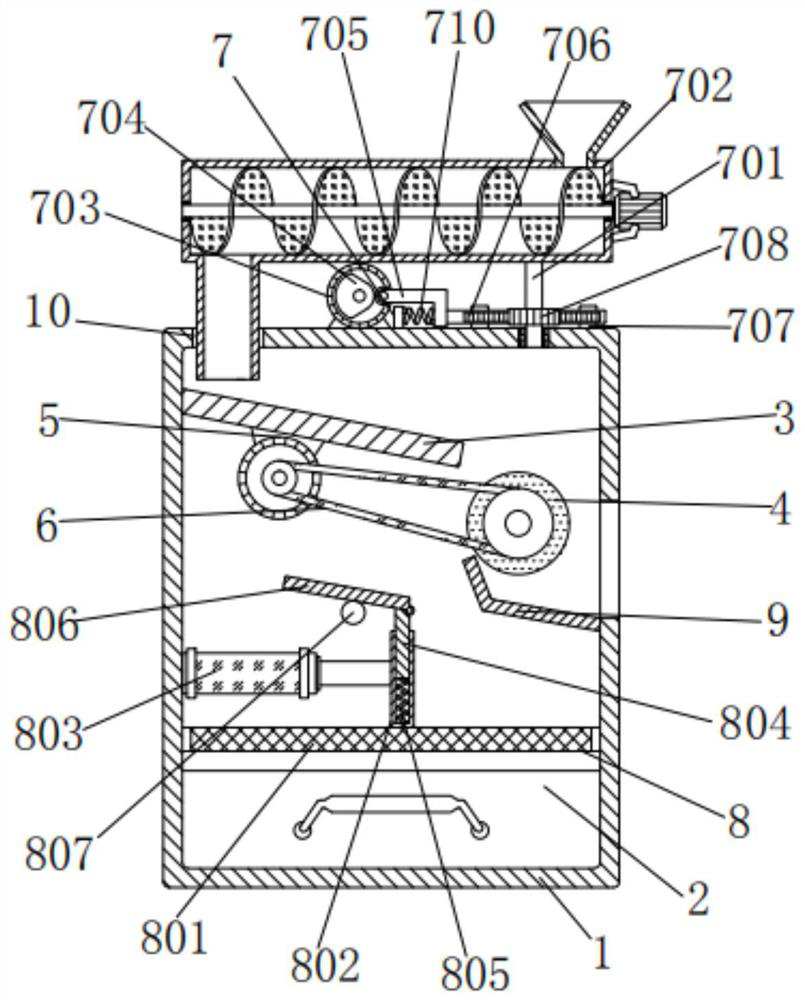

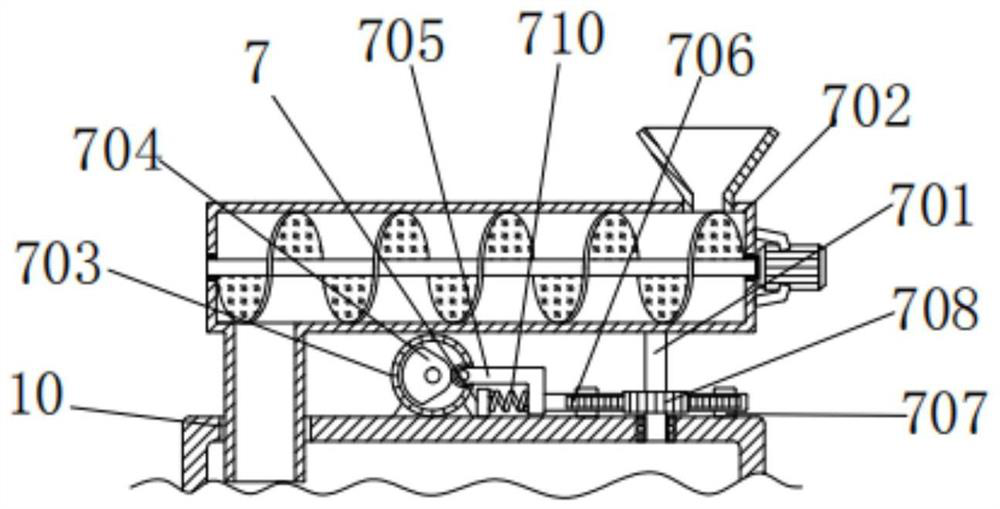

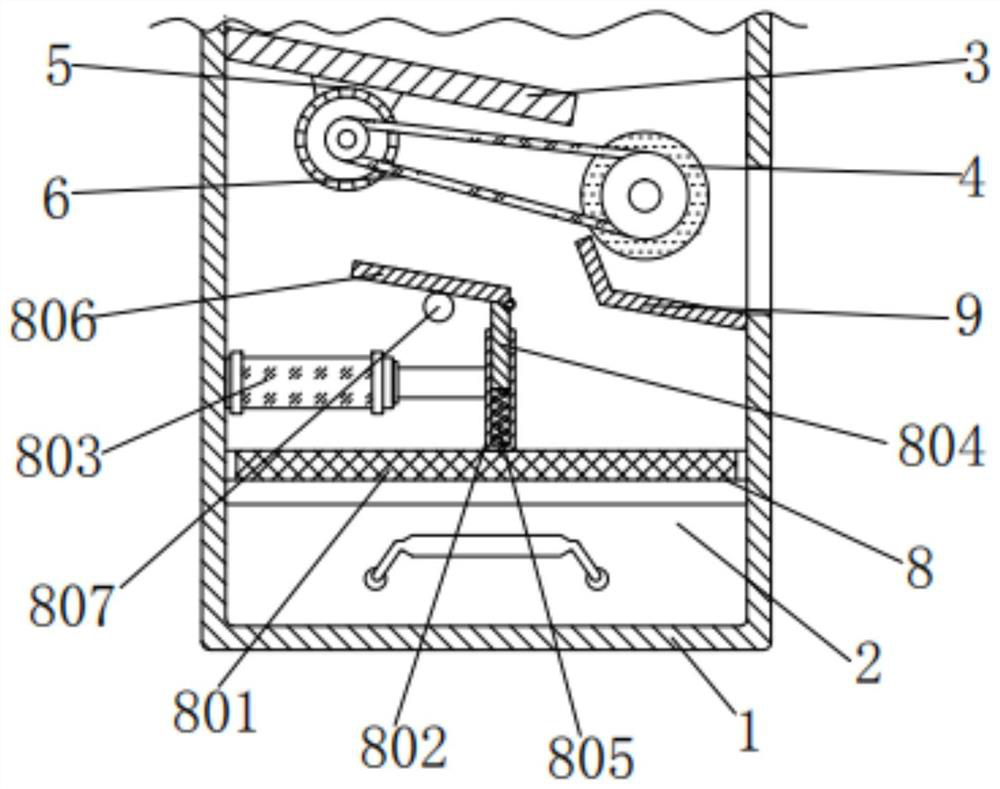

[0037] A multi-functional construction waste treatment equipment, comprising a box body 1, an opening 10 is processed on the top left side of the box body 1, a bracket 2 is placed at the bottom of the inner wall of the box body 1, and a slanting plate is fixedly connected to the left side of the inner wall of the box body 1 3. The right side of the inner wall of the box body 1 is connected with the magnetic roller 4, and the positions of the swash plate 3 and the magnetic roller 4 correspond one by one. The bottom of the magnetic roller 4 is pressed against the scraper 9. The right end of the inner wall is fixedly connected, the bottom of the swash plate 3 is fixedly connected with the first motor 5, the first motor 5 and the front preset sheave of the magnetic roller 4 are connected by belt 5 rotation, and the top of the box body 1 is provided with a blanking assembly 7 , the blanking assembly 7 includes a vertical bar 701, an auger conveyor 702, a second motor 703, a cam 704,...

Embodiment 2

[0039] As an option, see figure 1 , 3And 6, multi-functional construction waste treatment equipment, the inner bottom of the box body 1 is provided with a compression assembly 8, the compression assembly 8 includes a filter screen 801, a top plate 802, a cylinder 803, a vertical plate 804, a second spring 805, a baffle plate 806 and a circular Rod 807, filter screen 801 is fixedly connected below the inner wall of casing 1, the material of filter screen 801 is stainless steel, and its number of mesh is ten orders, and the top of filter screen 801 is pressed against has top plate 802, and the left end of top plate 802 is fixedly connected with Cylinder 803, the left end of the cylinder 803 is fixedly connected with the left end of the inner wall of the box body 1, the top gap of the top plate 802 is fitted with a riser 804, the bottom of the riser 804 is fixedly connected with the bottom of the inner wall of the top plate 802 through the second spring 805, the riser 804 The to...

Embodiment 3

[0042] An application of construction waste treatment equipment. When using the multi-functional construction waste treatment equipment, firstly connect the first motor 5 and the second motor 703 to an external power supply, and set the magnetic roller 4 clockwise through the setting of the belt 6 Put the scraps of construction waste into the auger conveyor 2, through the axial rotation of the cam 704, through the setting of the first spring 710, the cam 704 is pressed against the roller 711, and the gap between the rack 706 and the collar 707 is matched , so that the rack 706 can reciprocate left and right, and then drive the auger conveyor 2 to reciprocate through the reciprocating rotation of the gear 708, so that the material can be evenly distributed on the swash plate 3, and then guided to the left side of the magnetic roller 4 through the slant plate 3, and then The iron-containing substances in the material are adsorbed, and are exported to the box body 1 by scraping th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com