Low-temperature desulfurization and denitrification method of boiler smoke

A boiler flue gas, desulfurization and denitrification technology, applied in the field of desulfurization and denitrification, can solve the problems of secondary pollution and high operating costs, and achieve the effect of stable operation of the device and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The coke oven gas from the coke oven enters the crude debenzene unit, and the crude debenzene forms stream I, wherein the benzene concentration in stream I is 1000-4000 mg / m 3 Between, the concentration of naphthalene is 200~500mg / m 3 Between, the concentration of hydrogen sulfide is 100~500mg / m 3 Between; stream Ⅰ enters the comprehensive purification tower, the comprehensive purification tower contains ZSM molecular sieve adsorbent, removes aromatics and sulfides in the gas at the same time, and forms stream Ⅱ, the benzene concentration in stream Ⅱ is less than 1000mg / m 3 , naphthalene concentration is less than 4 mg / m 3 , the concentration of hydrogen sulfide is less than 4mg / m 3 ;Organic sulfur concentration is less than 4mg / m 3 ; Logistics II enters the boiler for combustion.

[0052] 160,000 cubic meters of boiler flue gas at 240°C, with a nitrogen oxide content of 500mg / m 3 , the sulfide content is 200 mg / m 3 , enter the waste heat boiler to generate steam,...

Embodiment 2

[0054] The coke oven gas from the coke oven enters the crude debenzene unit, and the crude debenzene forms stream I, wherein the benzene concentration in stream I is 1000-4000 mg / m 3 Between, the concentration of naphthalene is 200~500mg / m 3 Between, the concentration of hydrogen sulfide is 100~500mg / m 3 Between; stream Ⅰ enters the comprehensive purification tower, the comprehensive purification tower contains ZSM molecular sieve adsorbent, removes aromatics and sulfides in the gas at the same time, and forms stream Ⅱ, the benzene concentration in stream Ⅱ is less than 1000mg / m 3 , naphthalene concentration is less than 4 mg / m 3 , the concentration of hydrogen sulfide is less than 4mg / m 3 ;Organic sulfur concentration is less than 4mg / m 3 ; Logistics II enters the boiler for combustion.

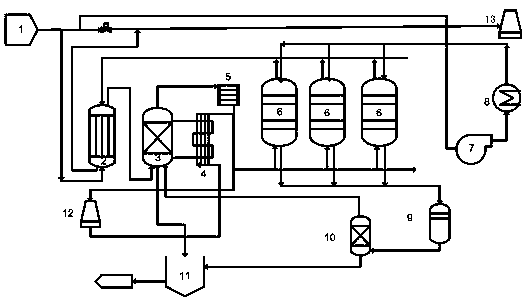

[0055] The specific implementation is as attached figure 1 The shown device flow, 150,000 cubic meters of flue gas at 260°C, the nitrogen oxide content is 400mg / m 3 , the sulfide conte...

Embodiment 3

[0057] The coke oven gas from the coke oven enters the crude debenzene unit, and the crude debenzene forms stream I, wherein the benzene concentration in stream I is 1000-3500 mg / m 3 Between, the concentration of naphthalene is 200~500mg / m 3 Between, the concentration of hydrogen sulfide is 100~500mg / m 3 Between; stream Ⅰ enters the comprehensive purification tower, which contains zinc-modified ZSM-5 molecular sieve adsorbent, and simultaneously removes aromatics and sulfides in the gas to form stream Ⅱ, in which benzene Concentration less than 60mg / m 3 , the concentration of naphthalene is less than 1 mg / m 3 , hydrogen sulfide concentration is less than 1mg / m 3 ; Concentration in toluene, xylene, ethylbenzene, trimethylbenzene, naphthalene, anthracene, and fennel is less than 1 mg / m 3 ;The concentration of sulfide is hydrogen sulfide, sulfur dioxide, mercaptan, thioether, thiophene, methyl mercaptan, methyl sulfide is less than 1 mg / m 3 , logistics II enters the boiler f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com