Arsenic sulfide slag comprehensive recovering process

A technology of arsenic sulfide and process, which is applied in the direction of sulfur compounds, arsenic compounds, and improvement of process efficiency. It can solve the problems of inability to obtain better comprehensive utilization, difficult disposal of high-arsenic gypsum slag, and unfriendly operating environment, so as to alleviate occupational problems. Effects of safety pressure, avoidance of fugitive emissions, and protection of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

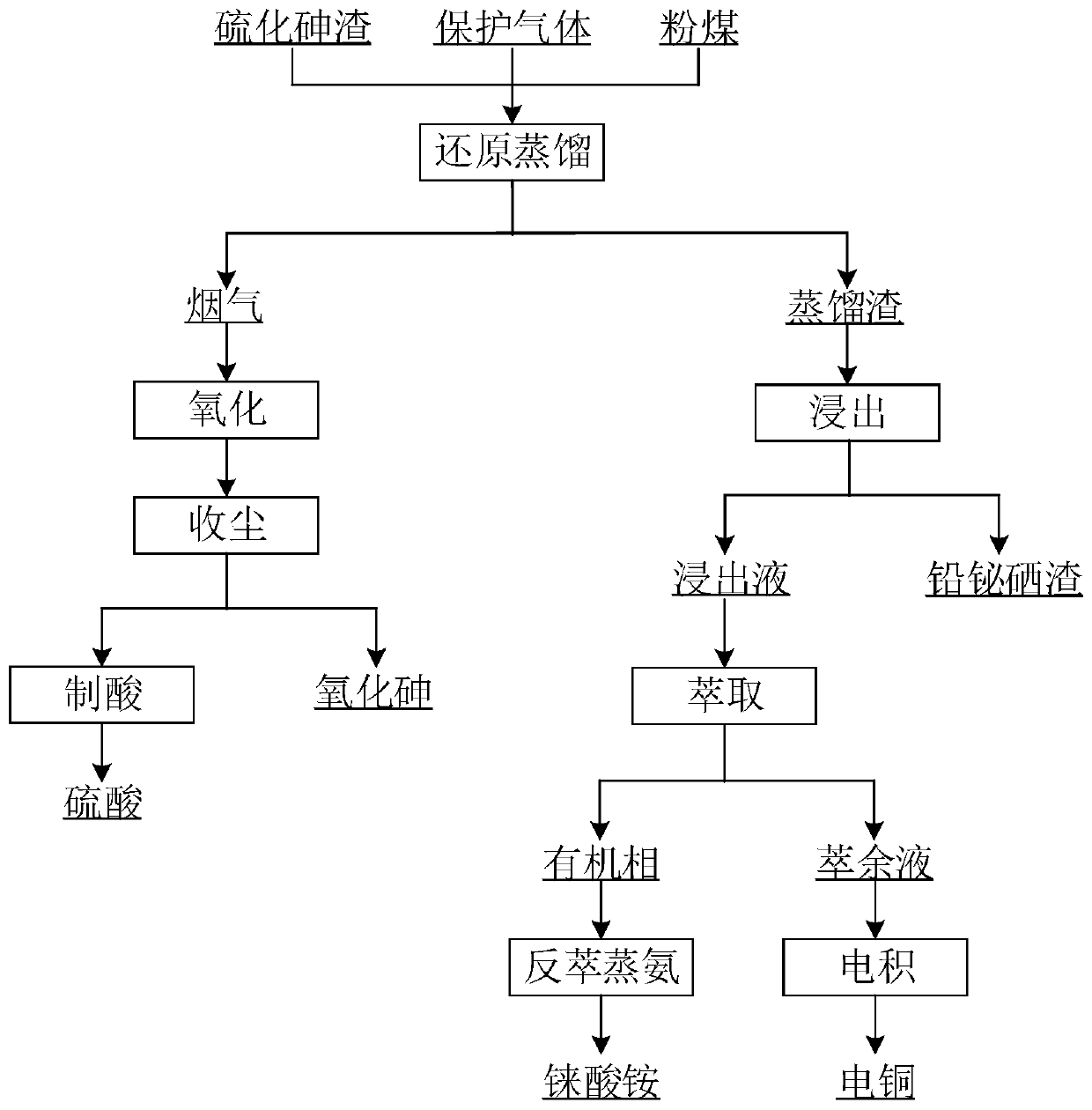

Image

Examples

Embodiment 1

[0028] The arsenic sulfide slag is used as the raw material for distillation treatment. The distillation process is as follows: the reducing agent is pulverized coal, the addition amount is 4% of the material amount of the arsenic sulfide slag, nitrogen is used as the protective gas, the temperature is 850 ℃, and the distillation is carried out for 5 hours. A mixed gas of arsenic sulfide and sulfur dioxide and a distillation residue are obtained. The distillation rate of arsenic sulfide is 92.8%, the distillation residue rate is 12.5%, and the enrichment of lead, copper, rhenium, bismuth and selenium is 8.12 times. The copper rhenium was leached from the distillation residue under neutral oxygen pressure. The leaching process was as follows: the leaching temperature was 150 °C, the oxygen pressure was 1.0 MPa, the liquid-solid ratio was 7:1, the stirring rate was 600 r / min, the reaction was 3 hours, and the copper rhenium leaching rate was 98.6%. , the leaching rate of rhenium...

Embodiment 2

[0030] The arsenic sulfide slag is used as the raw material for distillation treatment. The distillation process is as follows: the reducing agent is pulverized coal, the addition amount is 3% of the material amount of the arsenic sulfide slag, nitrogen is used as the protective gas, the temperature is 900 ℃, and the distillation is carried out for 3 hours. A mixed gas of arsenic sulfide and sulfur dioxide and a distillation residue are obtained. The distillation rate of arsenic sulfide is 91.2%, the distillation residue rate is 15.4%, and the enrichment of lead, copper, rhenium, bismuth and selenium is 6.49 times. The copper rhenium was leached from the distillation slag under neutral oxygen pressure. The leaching process was as follows: the leaching temperature was 100 °C, the oxygen pressure was 0.5 MPa, the liquid-solid ratio was 6:1, the stirring rate was 800 r / min, the reaction was 4 h, and the copper rhenium leaching rate was 96.8%. , the leaching rate of rhenium is 97....

Embodiment 3

[0032] The arsenic sulfide slag is used as the raw material for distillation treatment. The distillation process is as follows: the reducing agent is pulverized coal, the addition amount is 5% of the material amount of the arsenic sulfide slag, nitrogen is used as the protective gas, the temperature is 750 ℃, and the distillation is carried out for 5 hours. A mixed gas of arsenic sulfide and sulfur dioxide and a distillation residue are obtained. The distillation rate of arsenic sulfide is 87.5%, the distillation slag rate is 22.6%, and the enrichment of lead, copper, rhenium, bismuth and selenium is 4.42 times. The copper rhenium was leached from the distillation residue under neutral oxygen pressure. The leaching process was as follows: the leaching temperature was 100°C, the oxygen pressure was 0.8MPa, the liquid-solid ratio was 8:1, the stirring rate was 600r / min, the reaction was 4h, and the copper leaching rate was 98.7%. The leaching rate of rhenium was 98.8%, and lead,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com