Method for recycling gold and silver from high-arsenic gold concentrate

A high-arsenic gold concentrate and gold concentrate technology is applied in the direction of chemical instruments and methods, arsenic compounds, process efficiency improvement, etc. It can solve problems such as complicated procedures, difficult processing, and long time period, so as to improve processing efficiency, The effect of reducing production cost and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

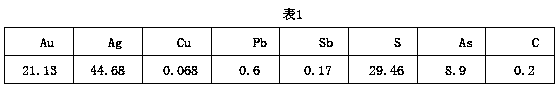

Embodiment 1

[0023] A method for recovering gold and silver in high-arsenic gold concentrate, comprising the steps of:

[0024] 1) Desulfurization and arsenic removal: The high-arsenic gold concentrate and water are made into pulp according to the mass ratio of 70:30, and the pulp is pumped to the two-stage roaster for desulfurization and dearsenization. 620°C to obtain calcined slag;

[0025] 2) Acid leaching pretreatment: mix the roasted slag and dilute sulfuric acid at a mass ratio of 1:2, the concentration of dilute sulfuric acid is 20%, react for 1.5h at a temperature of 80°C and a speed of 120r / min, and filter to obtain a pretreated slag and pickling solution;

[0026] 3) Acid leaching solution treatment: add lime to the acid leaching solution, adjust PH value = 6, filter to obtain multi-element arsenic-containing slag and filtrate 1, continue to add lime to filtrate 1 until PH = 8, filter to obtain iron-containing gypsum slag and filtrate 2. The filtrate 2 is made into dilute sulf...

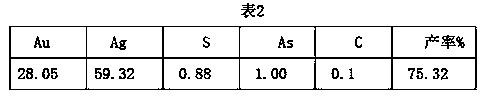

Embodiment 2

[0040] A method for recovering gold and silver in high-arsenic gold concentrate, comprising the steps of:

[0041] 1) Desulfurization and arsenic removal: The high-arsenic gold concentrate and water are made into pulp according to the mass ratio of 70:40, and the pulp is pumped to the two-stage roaster for desulfurization and dearsenization. 650°C to obtain calcined slag;

[0042] 2) Acid leaching pretreatment: mix roasted slag and dilute sulfuric acid at a mass ratio of 1:3, dilute sulfuric acid concentration is 30%, react for 2 hours at a temperature of 85°C and a speed of 200r / min, and filter to obtain pretreated slag and pickling solution;

[0043] 3) Acid leaching solution treatment: add lime to the acid leaching solution, adjust PH value = 6, filter to obtain multi-element arsenic-containing slag and filtrate 1, continue to add lime to filtrate 1 until PH = 8, filter to obtain iron-containing gypsum slag and filtrate 2. Filtrate 2 is made into dilute sulfuric acid with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com