Method for comprehensively recovering valuable metals from arsenic-containing copper smoke dust

A technology for valuable metals and dust, applied in the direction of arsenic compounds, chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, etc., can solve the problems of long production process and difficulty in comprehensive utilization, and achieve short process, The effect of high direct yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

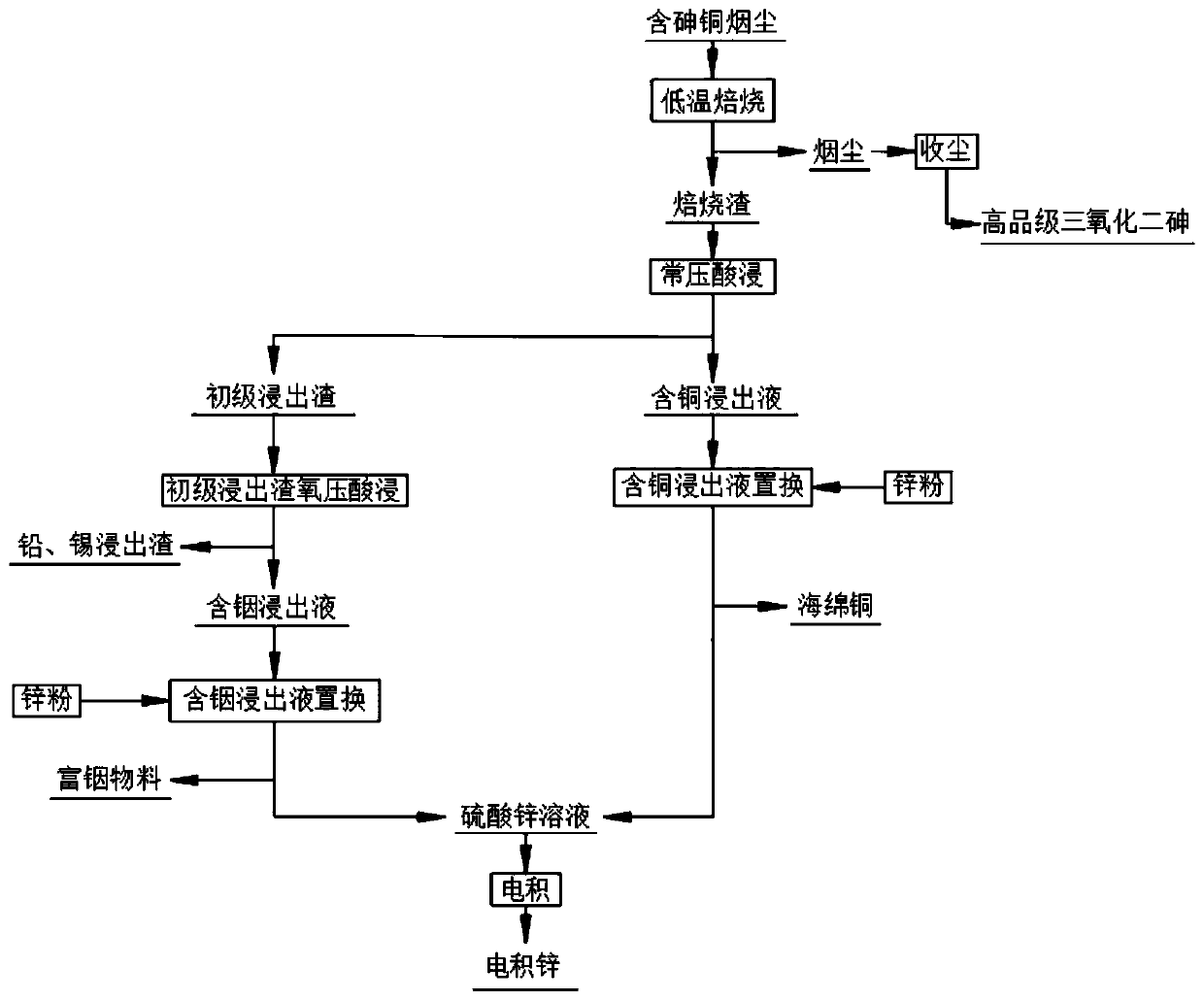

[0024] refer to figure 1 , a method for comprehensively recovering valuable metals from arsenic-containing copper fume, comprising the following steps:

[0025] A. Low temperature roasting: the ingredients are: arsenic: 9%-13%, copper 2-3%, zinc 12%-14%, indium 500-1000g / t, tin 3%-5%, lead 10%-13% The arsenic-containing copper soot is roasted at low temperature in a rotary kiln, and the temperature during low-temperature roasting is 300-370°C, and 3% of the total mass of the arsenic-copper soot and 3% of the total mass of the arsenic-copper soot are added. Copper oxide powder , the roasting time lasts for 2 hours; smoke dust and roasting slag are obtained during roasting, wherein the content of arsenic in the roasting slag is reduced to below 1%, and the smoke dust is arsenic trioxide, and the dust is further dust-collected to obtain high-grade arsenic trioxide;

[0026] B, atmospheric acid leaching: the roasted slag obtained in step A is leached by sulfuric acid with a conce...

Embodiment 2

[0032] refer to figure 1 , a method for comprehensively recovering valuable metals from arsenic-containing copper fume, comprising the following steps:

[0033] A. Low temperature roasting: the ingredients are: arsenic: 13%-17%, copper 3-5%, zinc 14%-17%, indium 1000-1500g / t, tin 5%-7%, lead 13%-17% The arsenic-containing copper soot is roasted at low temperature in a rotary kiln, and the temperature during low-temperature roasting is 370-450°C, and 4% of the total mass of the arsenic-copper soot and 7% of the total mass of the arsenic-copper soot are added. Copper oxide powder , the roasting time lasts for 2.5 hours; smoke dust and roasting slag are obtained during roasting, wherein the content of arsenic in the roasting slag is reduced to below 1%, and the smoke dust is arsenic trioxide, and the dust is further dust-collected to obtain high-grade arsenic trioxide;

[0034] B, atmospheric acid leaching: the roasted slag obtained in step A is leached by sulfuric acid with a c...

Embodiment 3

[0040] refer to figure 1 , a method for comprehensively recovering valuable metals from arsenic-containing copper fume, comprising the following steps:

[0041] A. Low temperature roasting: the ingredients are: arsenic: 17%-20%, copper 5%-6%, zinc 17%-20%, indium 1500-2000g / t, tin 7%-8%, lead 17%-20 % of the arsenic-containing copper dust is roasted at a low temperature in a rotary kiln, and the temperature during low-temperature roasting is 450-500°C, and 5% of the total mass of the arsenic-copper fume and 10% of the total mass of the arsenic-copper fume are added. Copper oxide powder, and the roasting time lasts for 3 hours; smoke and roasted slag are obtained during roasting, wherein the content of arsenic in the roasted slag is reduced to below 1%, and the smoke is arsenic trioxide, and the dust is further dust-collected to obtain high-grade diarsenic trioxide;

[0042] B, atmospheric acid leaching: the roasted slag obtained in step A is leached by sulfuric acid with a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com