Oyster polypeptide-nano selenium granule compound having hangover-relieving and liver-protecting effects and preparation method and application thereof

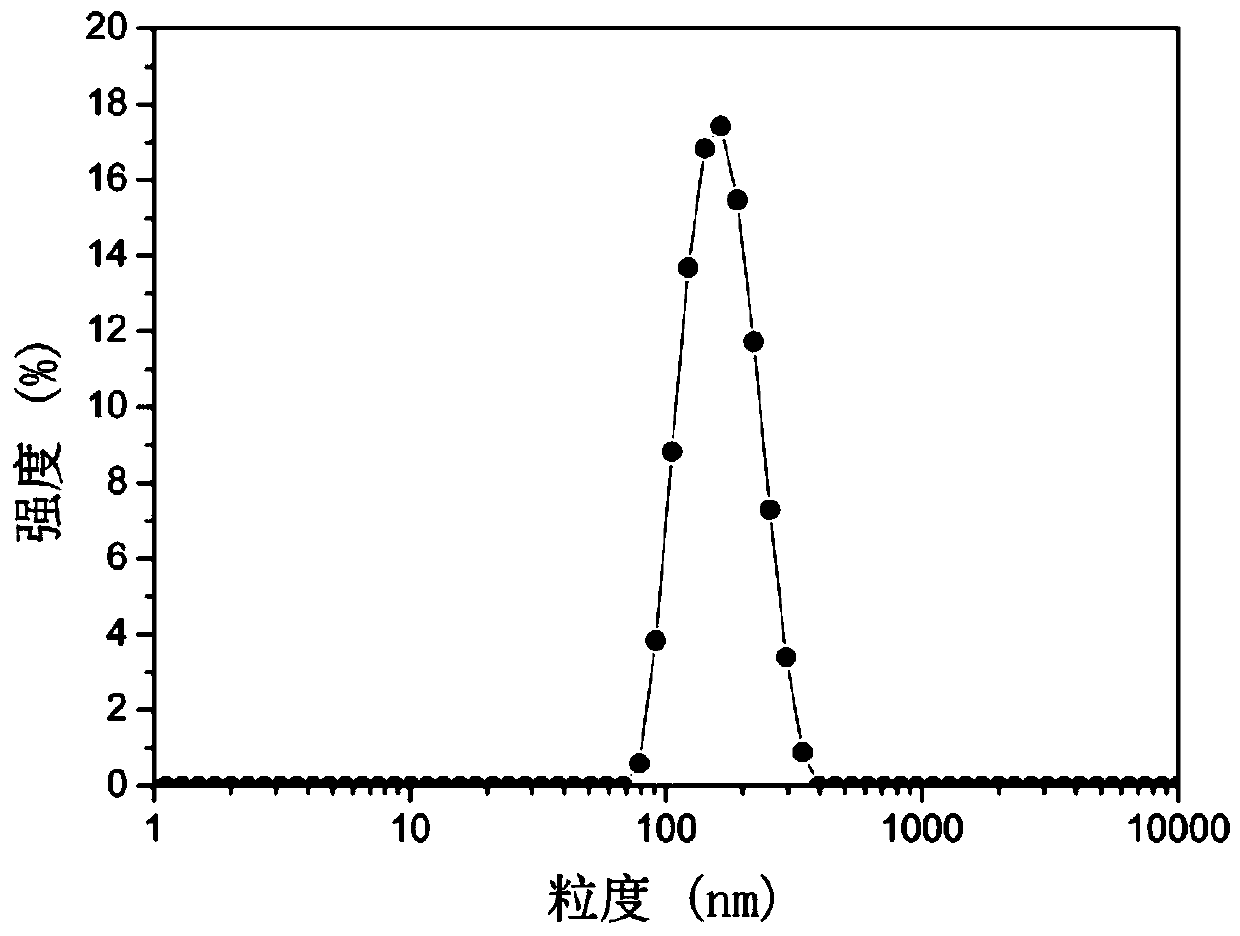

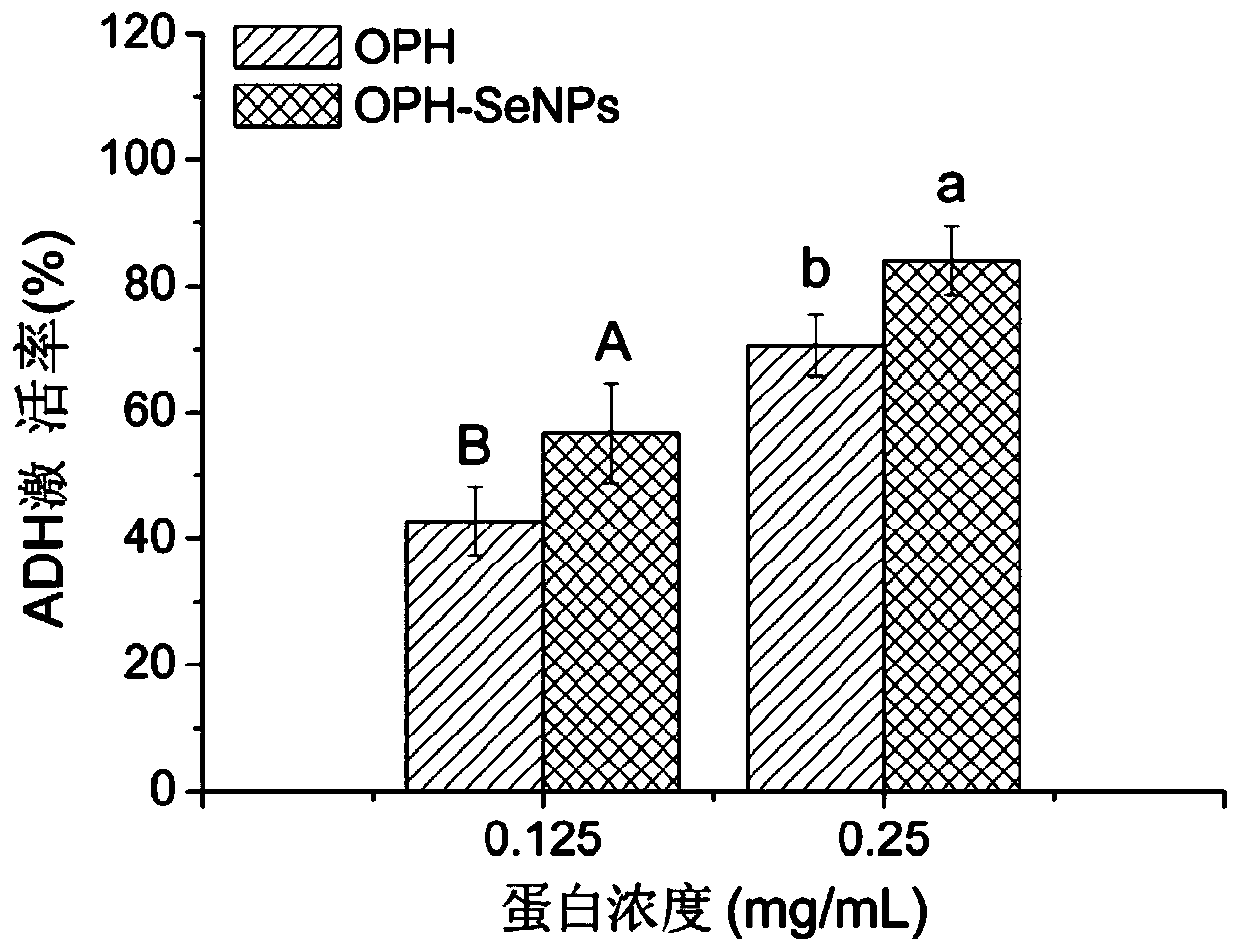

A particle complex, oyster polypeptide technology, applied in application, food science, function of food ingredients, etc., can solve the problems of nano selenium size regulation stability and active molecule enrichment efficiency, achieve good hangover and liver protection, improve stability Sexual, effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of an oyster polypeptide-nano selenium particle complex having the effect of relieving alcohol and protecting the liver, comprising the following steps:

[0045] (1) Using commercially available oysters as raw materials, remove the shells and take the meat, wash the meat and homogenate directly (the homogenization speed is 12000 r / min, and the homogenization time is 60 s) to form a homogenate liquid, and add water (homogenization time is 60 s). The mass ratio of slurry to water is 1:1), pancreatin is added for enzymolysis, the enzymolysis conditions are: pH 7.0, the enzyme addition amount is 0.1% (w / w) (that is, the enzyme addition amount is 0.1% of the mass of oyster meat %), the reaction temperature was 60 °C, and the reaction time was 4 h. After the enzymatic hydrolysis reaction, inactivate the enzyme in a boiling water bath for 10 min, centrifuge at 8000 r / min at 4 °C for 30 min, and freeze-dry the obtained supernatant (the pre-freezing temperat...

Embodiment 2

[0048] A preparation method of an oyster polypeptide-nano selenium particle complex having the effect of relieving alcohol and protecting the liver, comprising the following steps:

[0049] (1) Using commercially available oysters as raw materials, remove the shells and take the meat, wash the meat and homogenate directly (the homogenization speed is 12000 r / min, and the homogenization time is 60 s) to form a homogenate liquid, and add water (homogenization time is 60 s). The mass ratio of slurry to water is 1:1), adding trypsin Papain for enzymolysis, the conditions of enzymolysis are: pH 5, the enzyme addition amount is 1% (w / w) (that is, the enzyme addition amount is 1% of the mass of oyster meat %), the reaction temperature was 37°C, and the reaction time was 12 h. After the enzymatic hydrolysis reaction, inactivate the enzyme in a boiling water bath for 15 minutes, centrifuge at 10,000 r / min for 10 minutes at 10°C, and freeze-dry the obtained supernatant (the pre-freezing...

Embodiment 3

[0052] A preparation method of an oyster polypeptide-nano selenium particle complex having the effect of relieving alcohol and protecting the liver, comprising the following steps:

[0053] (1) Using commercially available oysters as raw materials, remove the shells and take the meat, wash the meat and homogenate directly (the homogenization speed is 12000 r / min, and the homogenization time is 60 s) to form a homogenate liquid, and add water (homogenization time is 60 s). The mass ratio of slurry to water is 1:2), adding 2.4 L of alkaline protease Alcalase for enzymolysis, the enzymolysis conditions are: pH 11, the enzyme addition is 0.4% (w / w) (that is, the enzyme addition is oyster 0.4% of the meat mass), the reaction temperature was 40°C, and the reaction time was 0.5 h. After the enzymatic hydrolysis reaction, inactivate the enzyme in a boiling water bath for 10 min, centrifuge at 10,000 r / min at 4 °C for 15 min, and freeze-dry the obtained supernatant (the pre-freezing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com