Efficient method for enriching rhenium from high-arsenic copper sulfide material containing rhenium

A copper sulfide enrichment technology, applied in the direction of improving process efficiency, can solve the problems of small specific volume, low cost, short process, etc., and achieve the effect of simple operation, strong material adaptability and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

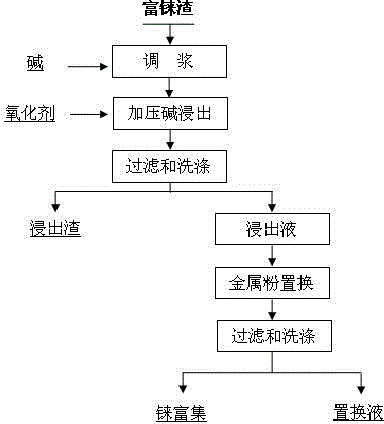

[0030] See attached figure 1 , conditions: 100 grams of rhenium-rich slag, the ratio of potassium hydroxide is 100% of the weight ratio of rhenium-rich slag, after pulping, pressurized leaching: solid-liquid ratio 8:1, leaching time 1 hour, leaching temperature 100 ° C, The stirring speed is 150 rpm, and the oxygen partial pressure is 0.7MPa. After the reaction, it was taken out and filtered, washed with 200 ml of water, and the leached residue was dried and then sent for analysis. Under these conditions, the leaching rate of rhenium was 98.7%, and the pH of the leaching solution was 12.5. For the leaching solution, metal powder is used to replace and enrich rhenium. The conditions are: the amount of active aluminum metal powder is 2.0 times the theoretical amount, the replacement temperature is 60°C, the time is 4.0h, and the replacement rate is 95.15%. The enrichment ratio of rhenium in the whole process is 35.12%, and the recovery rate is 93.91%.

Embodiment 2

[0032] See attached figure 1 , Conditions: 100 grams of rhenium-rich slag, the proportion of sodium hydroxide is 80% of the weight ratio of rhenium-rich slag, after pulping, pressurized leaching: solid-liquid ratio 5:1, leaching time 2 hours, leaching temperature 120 ° C, The stirring speed is 150 rpm, the oxidizing agent is industrial oxygen, and the partial pressure of oxygen is 0.5 MPa. After the reaction, it was taken out and filtered, washed with 200 ml of water, and the leached residue was dried and then sent for analysis. Under these conditions, the leaching rate of rhenium is 98.9%; the pH of the leach solution is 13.0. For the leaching solution, metal powder is used to replace and enrich rhenium. The conditions are: the amount of active zinc metal powder is 3.0 times the theoretical amount, the replacement temperature is 70 ° C, the time is 3.0 h, and the replacement rate is 95.67%. The enrichment ratio of rhenium in the whole process is 36.17%, and the recovery rat...

Embodiment 3

[0034] See attached figure 1 , Conditions: 100 grams of rhenium-rich slag, the ratio of potassium hydroxide is 70% of the weight ratio of rhenium-rich slag, after pulping, pressurized leaching: solid-liquid ratio 7:1, leaching time 4 hours, leaching temperature 140 ° C, The stirring speed is 150 rpm, the oxidant is air oxygen, and the partial pressure of oxygen is 0.6 MPa. After the reaction, it was taken out and filtered, washed with 200 ml of water, and the leached residue was dried and then sent for analysis. Under these conditions, the leaching rate of rhenium was 97.9%; the pH of the leach solution was 12.0. For the leaching solution, metal powder is used to replace and enrich rhenium. The conditions are: the amount of active aluminum metal powder is 4.0 times the theoretical amount, the replacement temperature is 50 ° C, the time is 2.0 h, and the replacement rate is 94.90%. The enrichment ratio of rhenium in the whole process is 34.28%, and the recovery rate is 92.91%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com