Crude lead oxidizing and refining process and device

A technology for oxidizing and refining crude lead, which is applied in the field of process and equipment for oxidizing and refining crude lead, can solve the problems of insufficient tin content, poor working environment, and large lead loss, etc., and achieve high tin removal rate, low cost, and low lead loss. small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

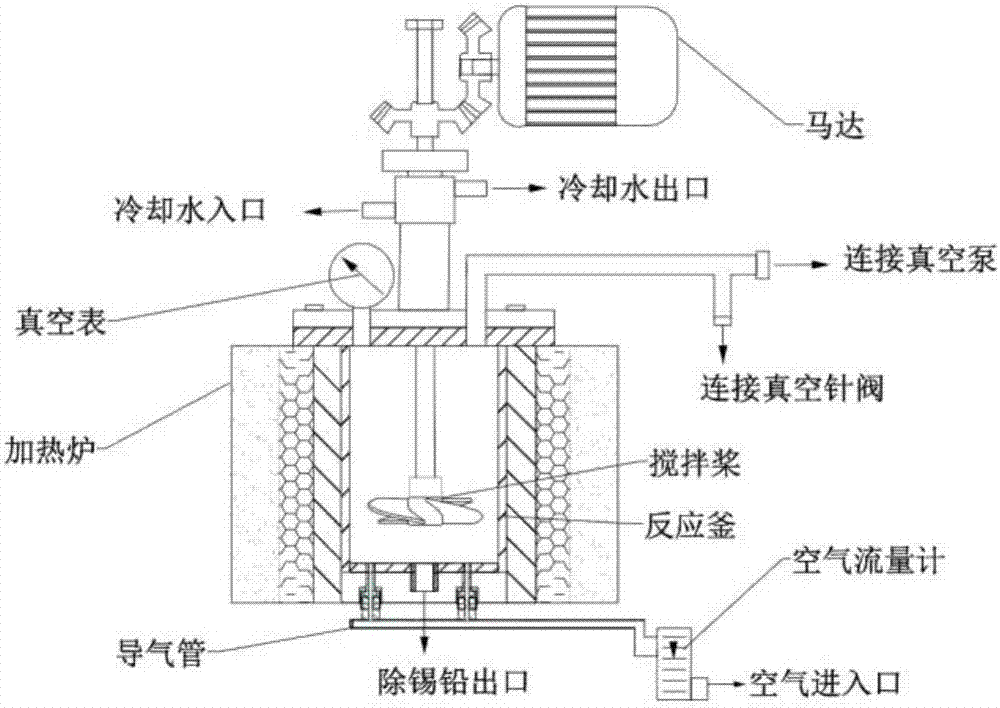

[0040] Weigh about 2kg of lead (the mass percentage of metal tin is about 0.2%) and place it in the experimental device, and react at a temperature of 750°C, a vacuum of 52kPa, a stirring speed of 100rpm, and an oxygen-enriched air volume of 60mL / min. The oxygen-enriched air is a mixture of pure oxygen and air. In this test, the oxygen-enriched air contains 50% air by volume. After 80 minutes, the tin content in the tin-lead removal is 1.1ppm, and the lead loss rate is 4.6%.

Embodiment 2

[0045] In embodiment 1, the oxygen-enriched air containing 50% air volume percentage is replaced by 100% air, and all the other remain unchanged, except that the tin content in tin-lead is 2ppm, and the lead loss rate is 2%. It shows that when only air is introduced, the content of Sn in excluding tin and lead is lower than 5ppm, which can also meet the requirements and reduce the oxidation loss of lead metal.

[0046] The following examples all use air as the oxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com