Patents

Literature

45results about How to "Meet the requirements of environmental performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble alkyd resin and water-soluble alcohol acid toy lacquer

ActiveCN101654514AMeet the requirements of environmental performanceAchieve zero VOCPolyester coatingsLacquerTrimethylolpropane

The invention relates to a water-soluble alkyd resin used for a toy lacquer, which comprises the following components in portion by weight: 180 to 200 portions of tall oil acid, 60 to 70 portions of trimellitic anhydride, 80 to 100 portions of diglycol, 50 to 60 portions of pentaerythritol, 30 to 40 portions of trimethylolpropane diallyl ether, 60 to 70 portions of dimethylolpropionic acid, 1 to 2portions of hypophosphorous acid, 8 to 10 portions of ammonia water, and 500 to 520 portions of vaal water. The invention also discloses a water-soluble alcohol acid toy lacquer prepared by using thewater-soluble alkyd resin as a principle component, and the synthesized water-soluble alkyd resin can be dried into a film without adding a drier; besides, because the formulation of the toy lacquerprepared by using the water-soluble alkyd resin as the principle component adopts water-soluble components, the toy lacquer achieves zero VOC, contains no heavy metal ions, and meets the requirementson the environmental protection performance of the resin.

Owner:珠海展辰新材料股份有限公司

Environment-friendly lead-free novel alloy material pipe and preparation method thereof

The invention provides an environment-friendly lead-free novel alloy material pipe and a preparation method thereof. The alloy material pipe is composed of the following components: zinc accounting for 1-3% of the total weight of the alloy material, tin accounting for 1-3% of the total weight of the alloy material, aluminum accounting for 0.5-2.5% of the total weight of the alloy material, antimony accounting for 0.05-0.5% of the total weight of the alloy material, silicon accounting for 0.5-1% of the total weight of the alloy material, and the balance of copper. According to the environment-friendly lead-free novel alloy material pipe, the traditional lead element is replaced by the silicon element; zinc, tin, aluminum, antimony, silicon and copper are blended in a certain ratio and continuously cast at an appropriate temperature to form a rough pipe casting; next, the rough pipe casting is extruded by an extruder to produce a tin bronze pipe completely containing no lead element; as a result, the mechanical properties, such as cutability, of the existing tin bronze are maintained without increasing cost, and the requirement on the environmental protection property of the alloy is also met.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

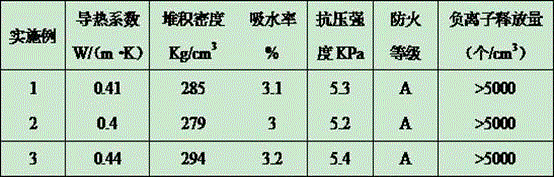

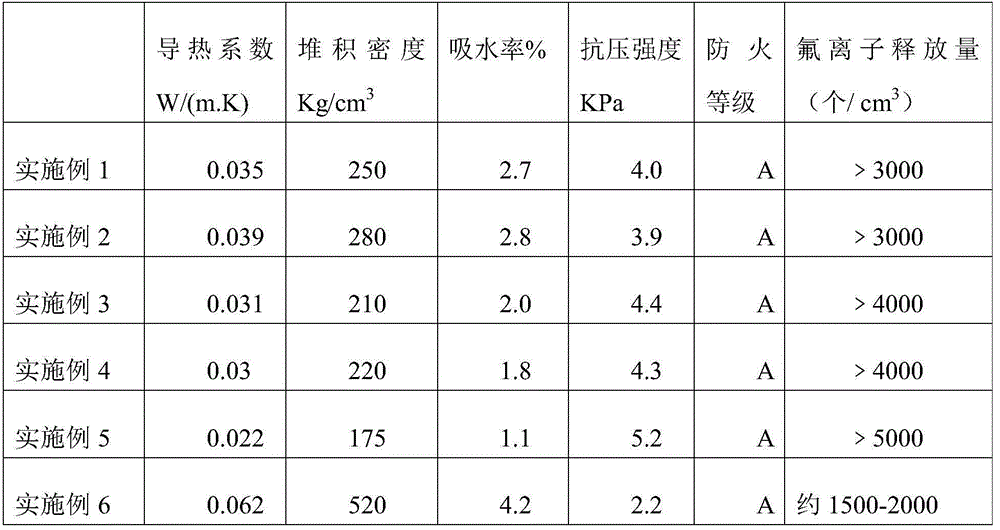

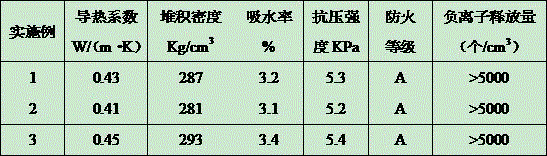

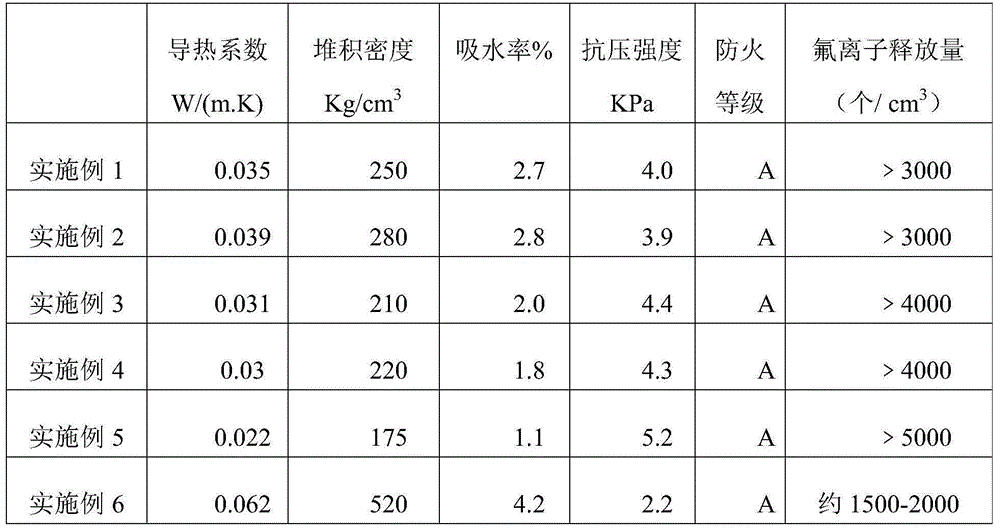

Environment-friendly building board and preparation method thereof

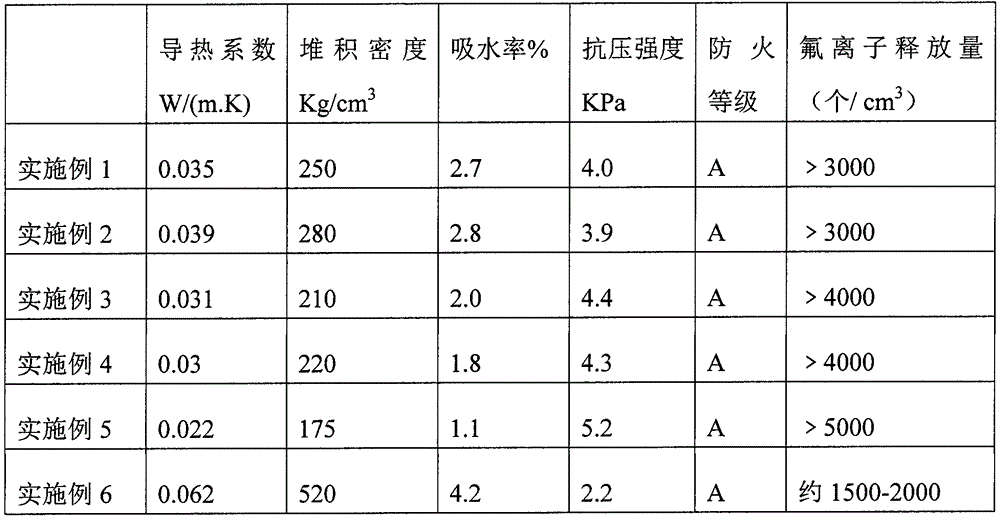

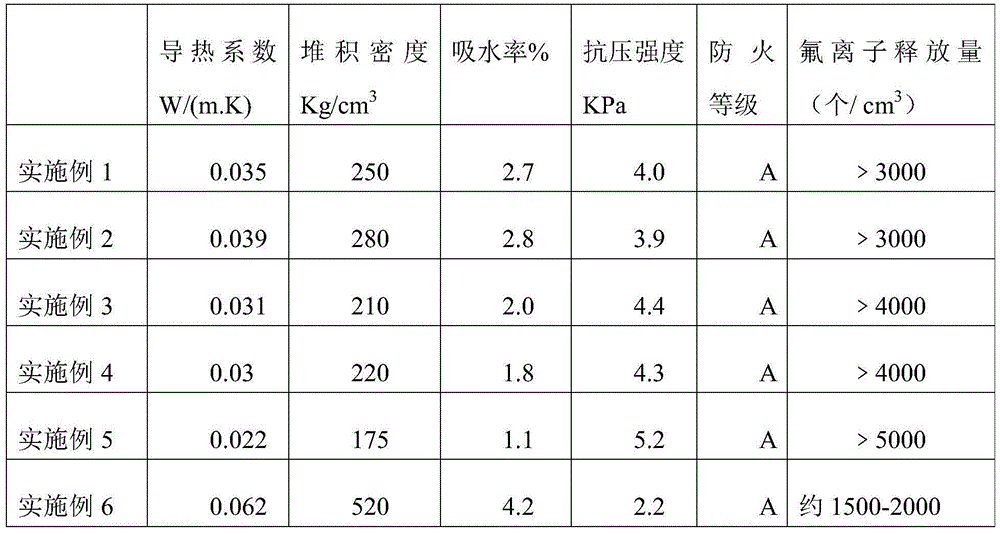

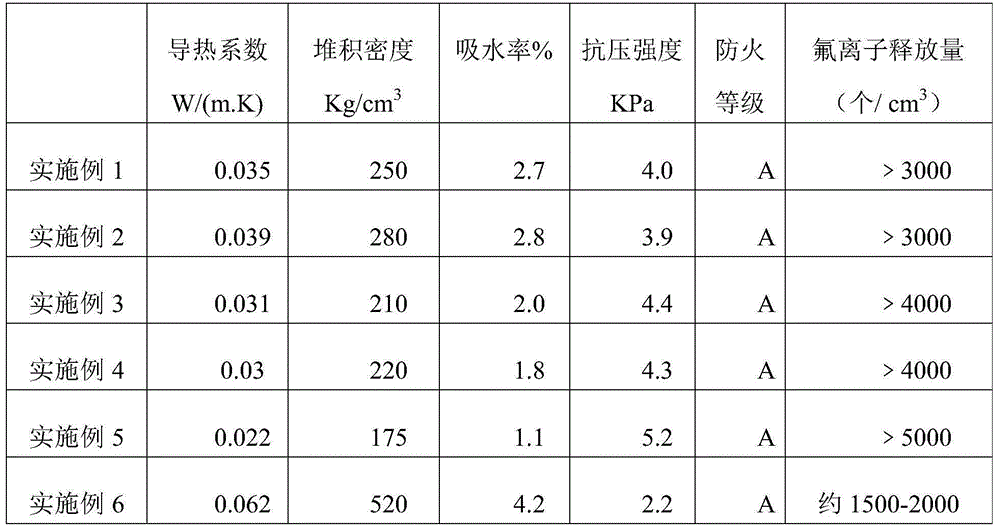

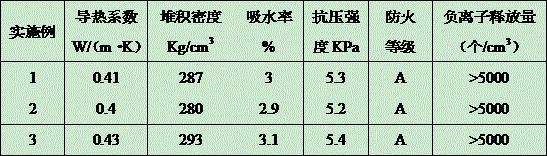

ActiveCN104016706AImprove light weightImprove insulation effectCeramicwareEnvironmental resistanceThermal insulation

The invention belongs to the field of building materials and in particular relates to a lightweight, thermal-insulation and high-strength green environment-friendly building board and a preparation method thereof. The environment-friendly building board comprises the following components in parts by weight: 5-10 parts of cement, 3-12 parts of coal gangue, 4-15 parts of coal ash, 2-8 parts of paraffin, 7-13 parts of urea, 4-8 parts of sulfomethylated phenolic resin, 6-14 parts of glass fiber, 8-15 parts of bentonite, 3-9 parts of methyl cellulose, 1-5 parts of mullite, 2-5 parts of medical stone, 2-5 parts of zeolite, 1-6 parts of sulfonylmethyl lignite, 4-15 parts of hydroxyethyl cellulose, and 0.5-1.5 parts of a foaming agent. The environment-friendly building board disclosed by the invention has the advantages of lightweight, excellent thermal-insulation, fire-proof and high-strength performances, which are much higher than the requirements of national and industry standards.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

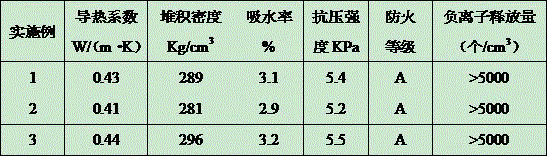

Environment-friendly building board and preparation method thereof

InactiveCN104086212AImprove light weightImprove insulation effectCeramicwareEnvironmental resistancePerformance index

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 3 to 12 parts of gangue, 4 to 15 parts of fly ash, 2 to 8 parts of paraffin, 7 to 13 parts of urea, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:南通和鼎智能科技股份有限公司

Improved environment-friendly building board and preparation method thereof

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 3 to 12 parts of gangue, 2 to 8 parts of paraffin, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 6 to 14 parts of a glass fiber, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:GAOYOU MINGZENG BIOLOGICAL PROD CO LTD

Novel environment-friendly building board

The invention discloses a novel environment-friendly building plate, which comprises the following raw materials in parts by weight: 22-40 parts of cement, 4-6 parts of shale ore, 2-3 parts of fly ash, 1-2 parts of tailing sand, 1-2 parts of bentonite, 1-2 parts of kaolin, 2-4 parts of paraffin, 3-5 parts of sulfomethyl phenolic resin, 2-3 parts of AR glass fiber, 2-3 parts of carboxymethyl cellulose, water reducing 0.6-1.2 parts of agent, 0.4-0.6 parts of foaming agent, 0.4-0.6 parts of foam regulator, 0.1-0.2 parts of catalyst, 0.3-0.6 parts of crosslinking agent, 0.1-0.2 parts of foam stabilizer, 15- parts of glyoxal 25 parts, hydrogen peroxide 10‑20 parts, water 200‑250 parts. The board prepared by the invention has excellent performances of light weight, heat preservation, fire prevention, high strength and environmental protection, and its performance index is far higher than the requirements of national and industry standards.

Owner:广西南宁桂尔创环保科技有限公司

Novel building board

InactiveCN106187278AImprove performanceReduce energy consumptionCeramicwareCarboxymethyl celluloseGlass fiber

The invention discloses a novel building board, which comprises the following raw materials in parts by weight: 25 to 38 parts of cement, 4 to 5 parts of slag, 2 to 3 parts of fly ash, 1 to 2 parts of ceramsite, 1 to 2 parts of shale, 1 to 2 parts of pumice stone, 2 to 4 parts of paraffin, 3 to 5 parts of sulfonated methyl phenolic resin (SMP), 2 to 3 parts of AR glass fiber, 2 to 3 parts of carboxymethyl cellulose, 0.6 to 1.2 parts of water reducer, 0.4 to 0.6 part of foaming agent, 0.4 to 0.6 part of foaming regulator, 0.1 to 0.2 part of catalyst, 0.3 to 0.6 part of crosslinking agent, 0.1 to 0.2 part of foam stabilizer, 20 to 25 parts of glyoxal, 12 to 20 parts of hydrogen peroxide, and 210 to 250 parts of water. The prepared board has excellent properties such as lightness, warming performance, fireproof property, high strength, environment-friendliness, and the like, and the performance indexes are far higher than the national and industrial standards.

Owner:广西南宁桂尔创环保科技有限公司

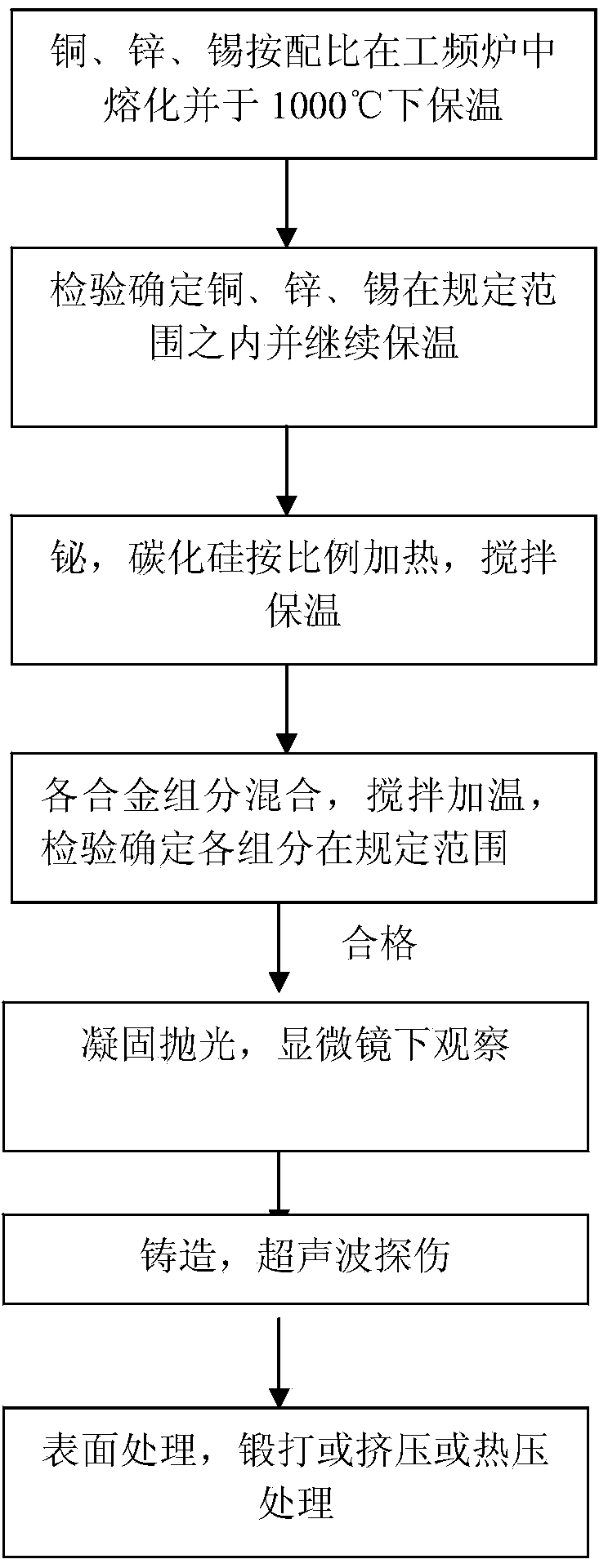

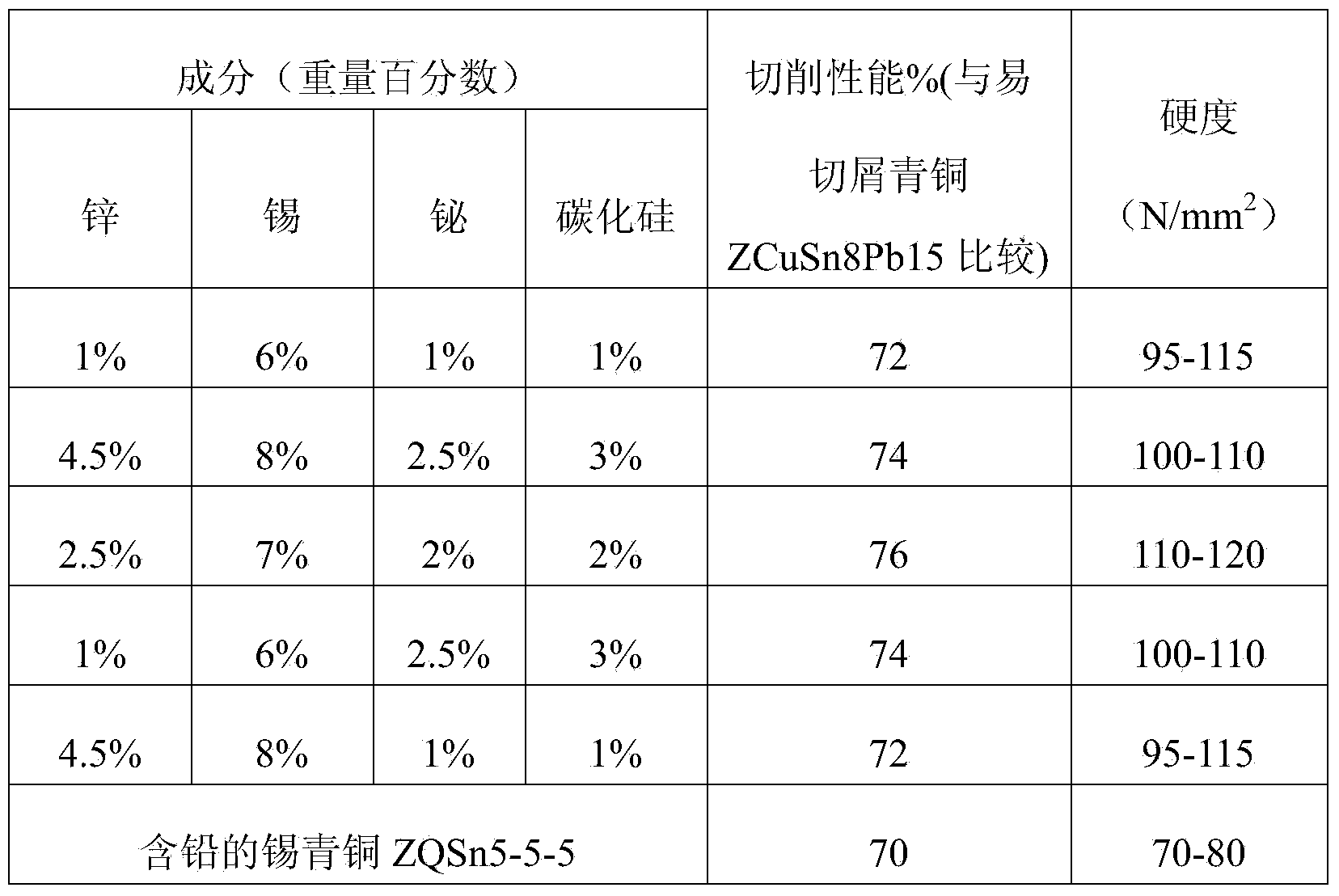

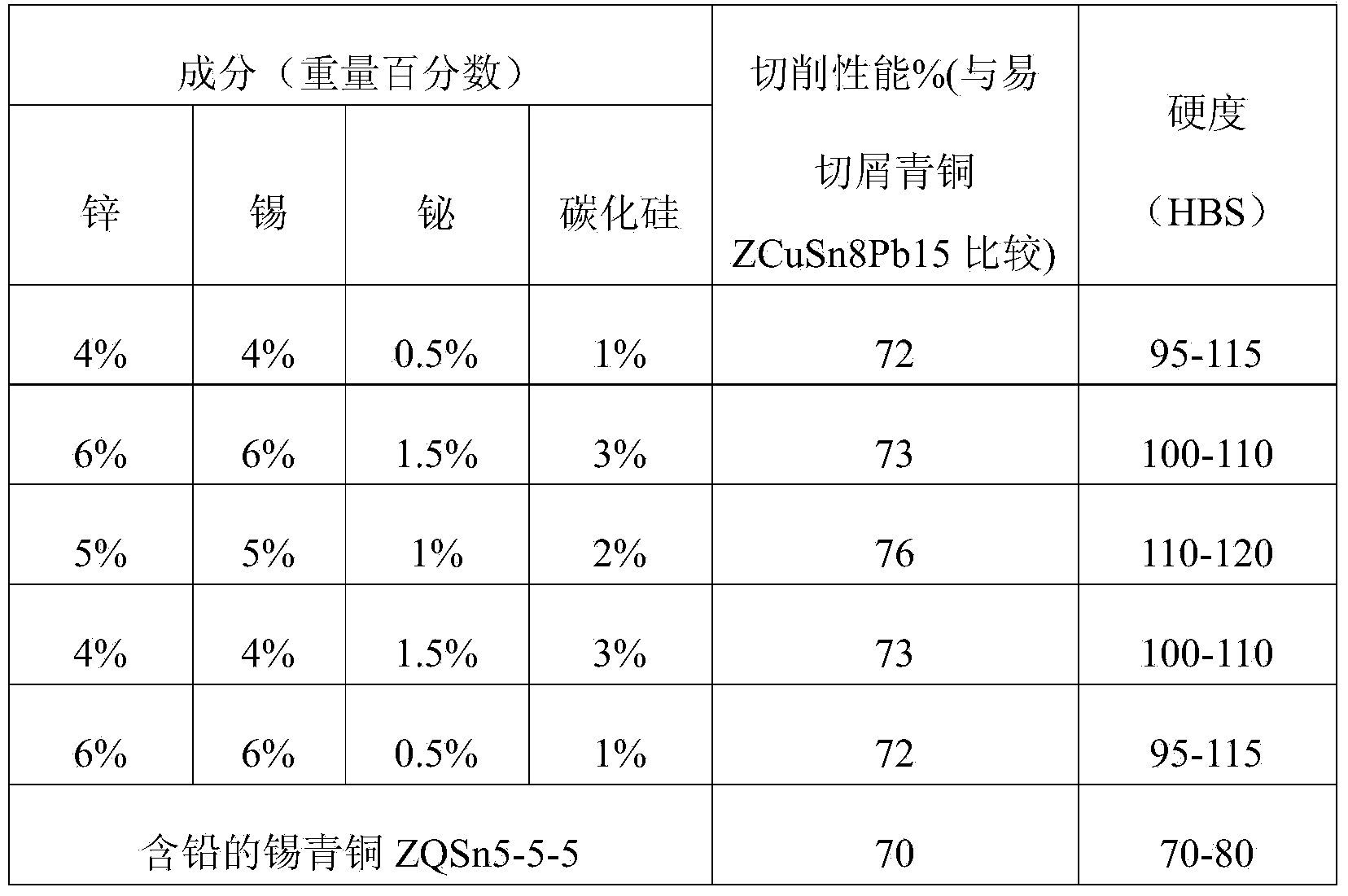

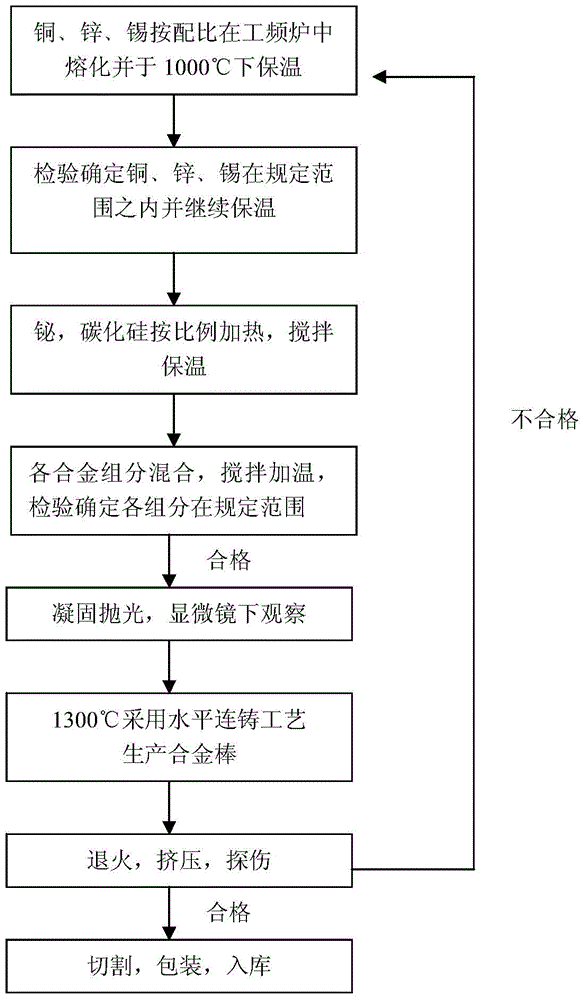

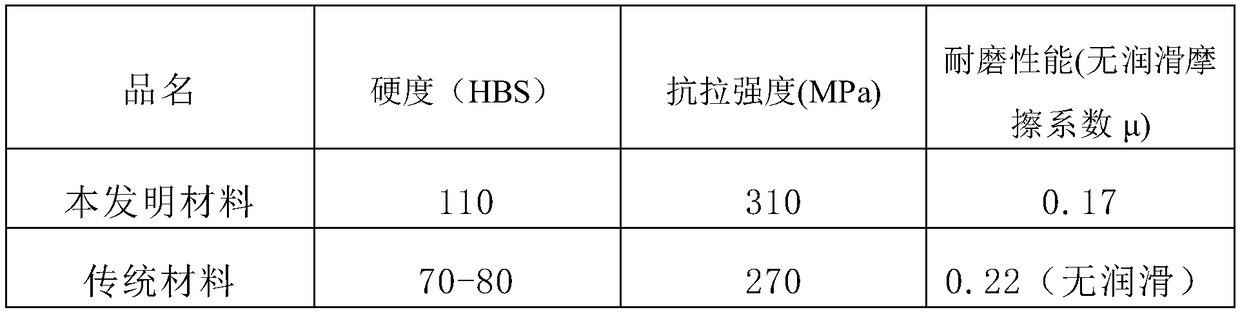

Novel lead-free environmental-friendly copper-based alloy material and manufacturing method thereof

ActiveCN103589902AMeet the requirements of environmental performanceImprove cutting performanceWear resistantHardness

The invention provides a novel lead-free environmental-friendly copper-based alloy material and a manufacturing method thereof. The novel lead-free environmental-friendly copper-based alloy material provided by the invention consists of the following components by weight: 1-4.5 percent of zinc, 6-8 percent of tin, 1-2.5 percent of bismuth, 1-3 percent of silicon carbide and the balance of copper. In the novel alloy material provided by the invention, the bismuth element is adopted to replace a lead element in a conventional copper alloy; a nanoscale silicon carbide material is added; by performance of expanding due to cold and contracting due to heat of bismuth and high toughness and high hardness of the nanoscale silicon carbide material, the novel lead-free environmental-friendly copper-based alloy material which completely can replace a tin bronze material containing the lead element is produced. According to the invention, under the condition of not increasing cost, the requirement on environmental-friendly performance of the alloy is met, cutting performance and hardness of the alloy are also further improved, and the novel lead-free environmental-friendly copper-based alloy material is suitable for a wear-resistant part at a high temperature (400 DEG C).

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Environment-friendly building board and preparation method thereof

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 4 to 15 parts of gangue, 2 to 8 parts of paraffin, 7 to 13 parts of urea, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 6 to 14 parts of a glass fiber, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:SHENZHEN KANGYA ECOLOGICAL ENVIRONMENT CO LTD

Water-soluble floor paint resin and application thereof

ActiveCN103059254AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolymer sciencePropanoic acid

The invention discloses a water-soluble floor paint resin and an application thereof. A production formula of the water-soluble floor paint resin comprises the following raw materials of, by weight, 180-200 parts of castor oil, 80-100 parts of HDI, 60-100 parts of diethylene glycol, 50-60 parts of pentaerythritol, 30-40 parts of trimethylolpropane diallyl ether, 60-70 parts of dimethylolpropionic acid, 1-2 parts of hypophosphorous acid, 8-10 parts of ammonia water and 150-200 parts of acetone. Air drying monomers of trimethylolpropane diallyl ether are introduced in the water-soluble floor paint resin to form a dual-curing system with NCO groups, so that film hardness and wear resistance are increased greatly. The water-soluble floor paint prepared by using the water-soluble floor paint resin as a main component realizes low VOC, has no free isocyanate monomers and can meet the requirements of environmental performance, because water-soluble components are adopted during a construction process.

Owner:珠海展辰新材料股份有限公司

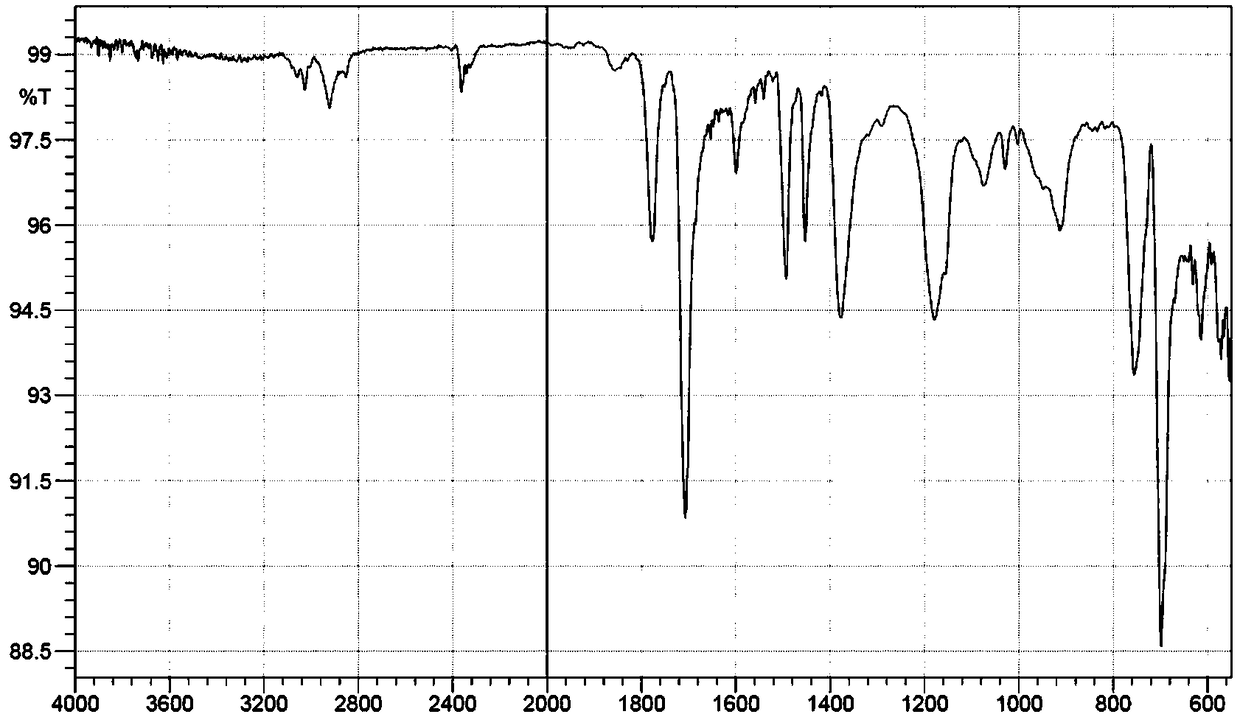

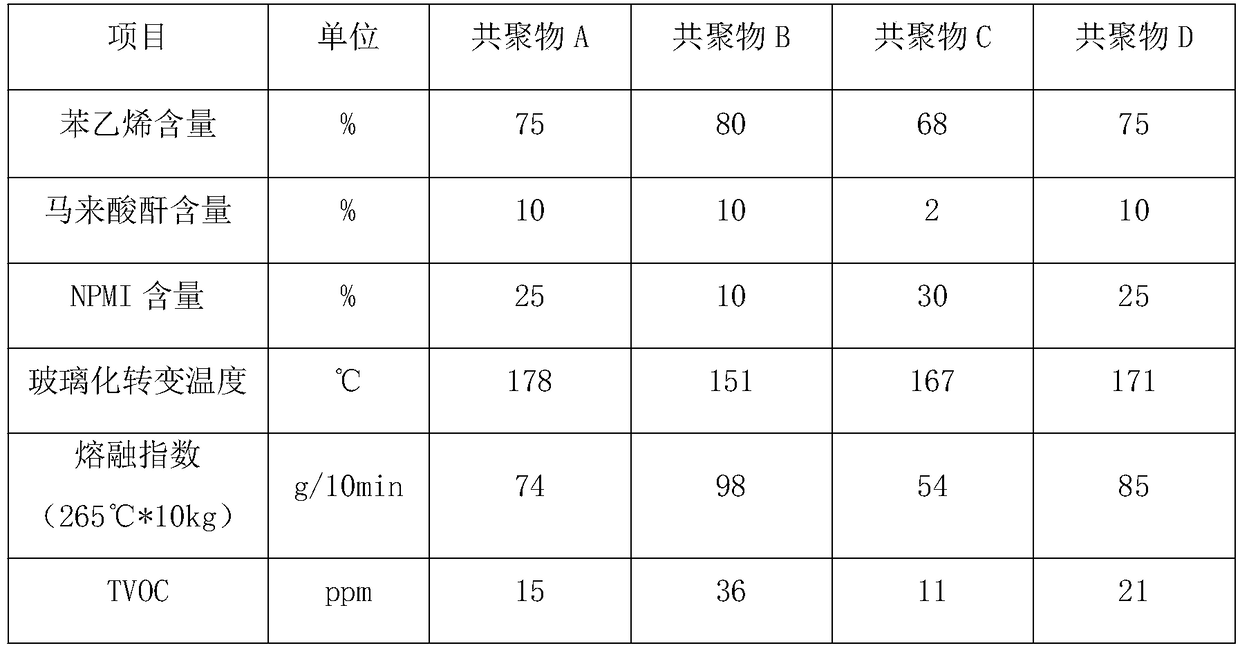

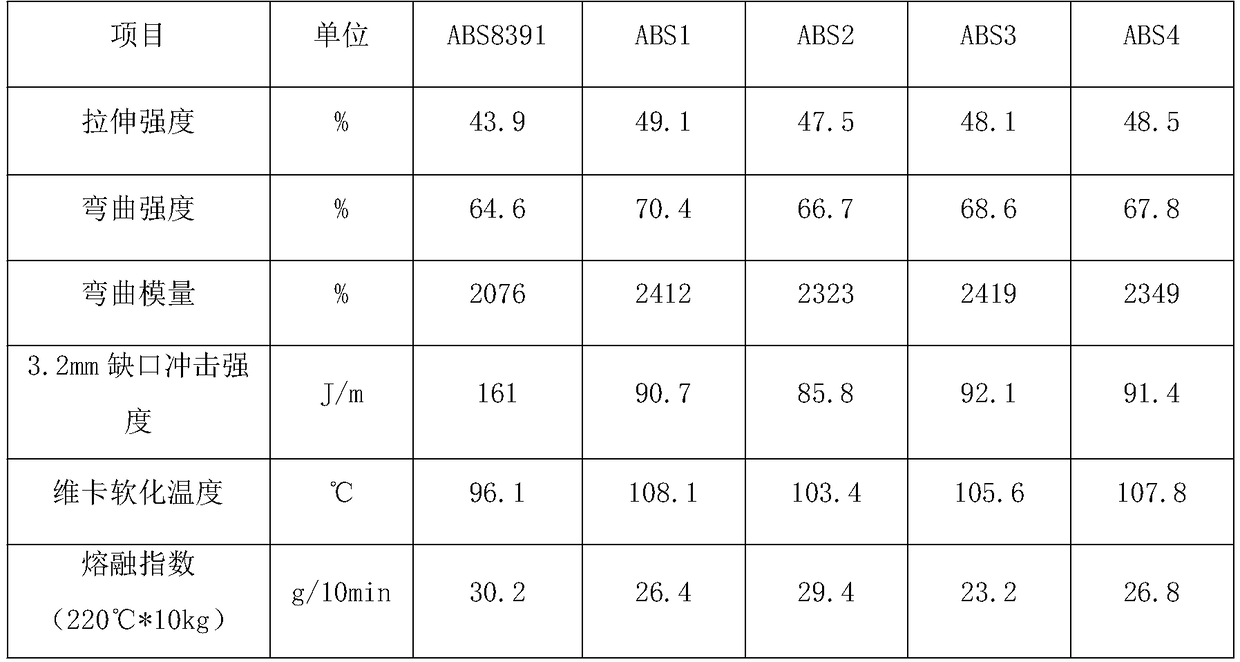

Preparation method of styrene-maleic anhydride-nitrophenyl maleimide terpolymer

The invention discloses a styrene-maleic anhydride-nitrophenyl maleimide terpolymer and a preparation method thereof. The terpolymer is characterized by comprising the following components by weight percentage: 50-90 parts of styrene, 1-20 parts of maleic anhydride, and 10-30 parts of nitrophenyl maleimide. The glass transition temperature is 150-200DEG C, a bulk polymerization way is employed forpreparation, firstly part of the styrene is added into a reaction kettle, then a styrene solution with dissolved maleic anhydride and nitrophenyl maleimide is added dropwise into the reaction kettle,the temperature of the reaction kettle is 90-140DEG C, and the pressure is atmospheric pressure, after reaction to a certain degree, high temperature vacuum devolatilization is carried out to obtainthe terpolymer. Compared with the prior art, the preparation method provided by the invention has the advantages of simple process, no waste water, and environment-friendly production process, and theprepared product has high purity, and is suitable for use as a low odor and low emission heat resistant agent for vehicle ABS and household appliance ABS.

Owner:嘉兴华雯化工股份有限公司

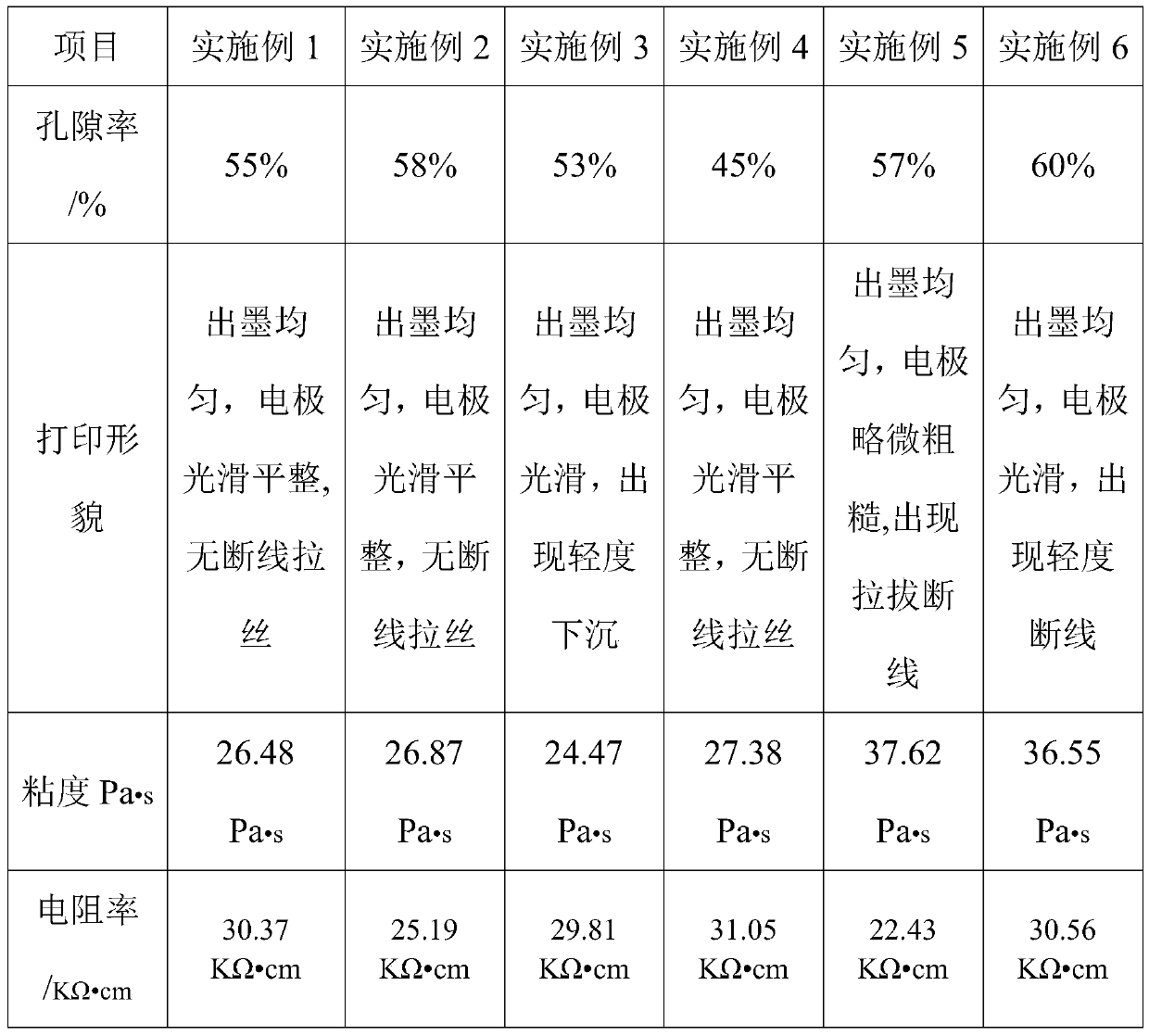

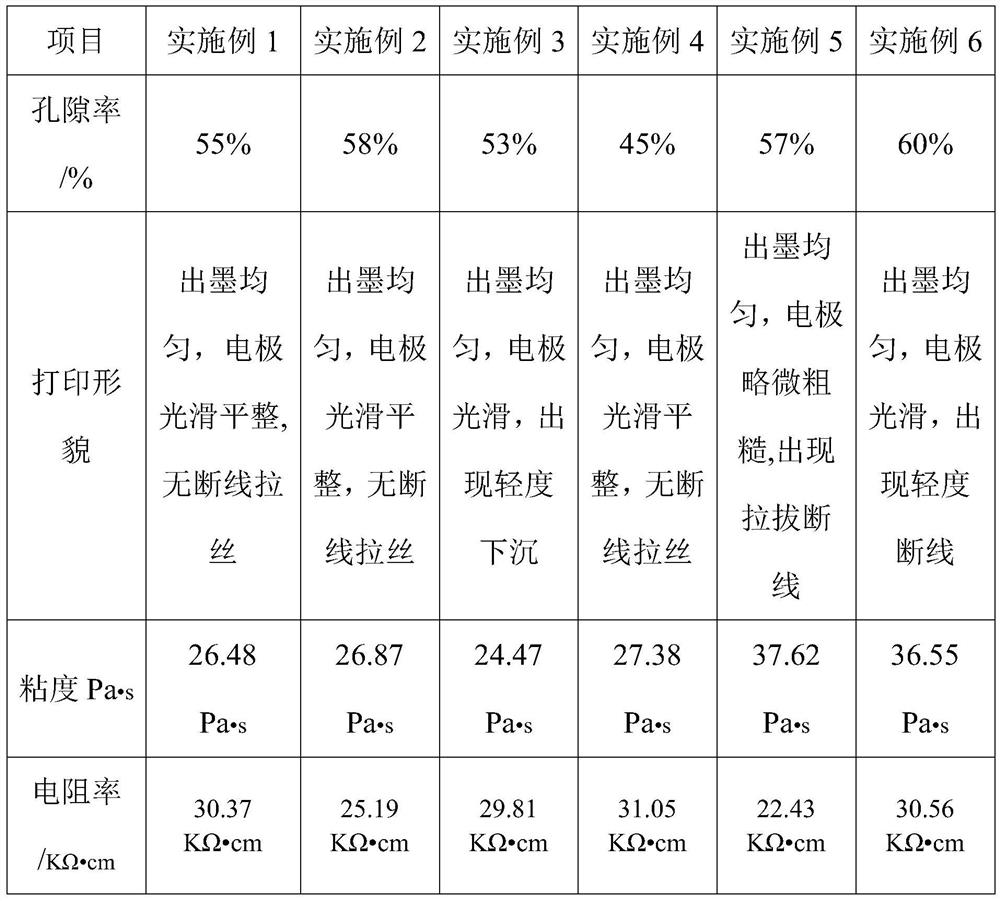

Lithium ion battery porous silicon electrode based on 3D printing technology

ActiveCN110350148ALow preparation temperatureSimple processElectrode manufacturing processesSecondary cellsSolventLithium-ion battery

The invention discloses a lithium ion battery porous silicon electrode based on a 3D printing technology. The lithium ion battery porous silicon electrode is composed of the following components in percentage by mass: 10-15% of a solvent I, 25-35% of a solvent II, 4-8% of a pore-forming agent, 45-55% of an electrode active material, 2-4% of a conductive reinforcing agent and 2% of a binder, wherein the total mass percentage is 100%. The invention further discloses a preparation method of the lithium ion battery porous silicon electrode based on the 3D printing technology. The prepared lithiumion battery porous silicon electrode based on the 3D printing technology is proper in porosity, excellent in cycling stability and excellent in conductive performance; and the preparation process is simple and meets the environment-friendly requirements.

Owner:高能数造(西安)技术有限公司

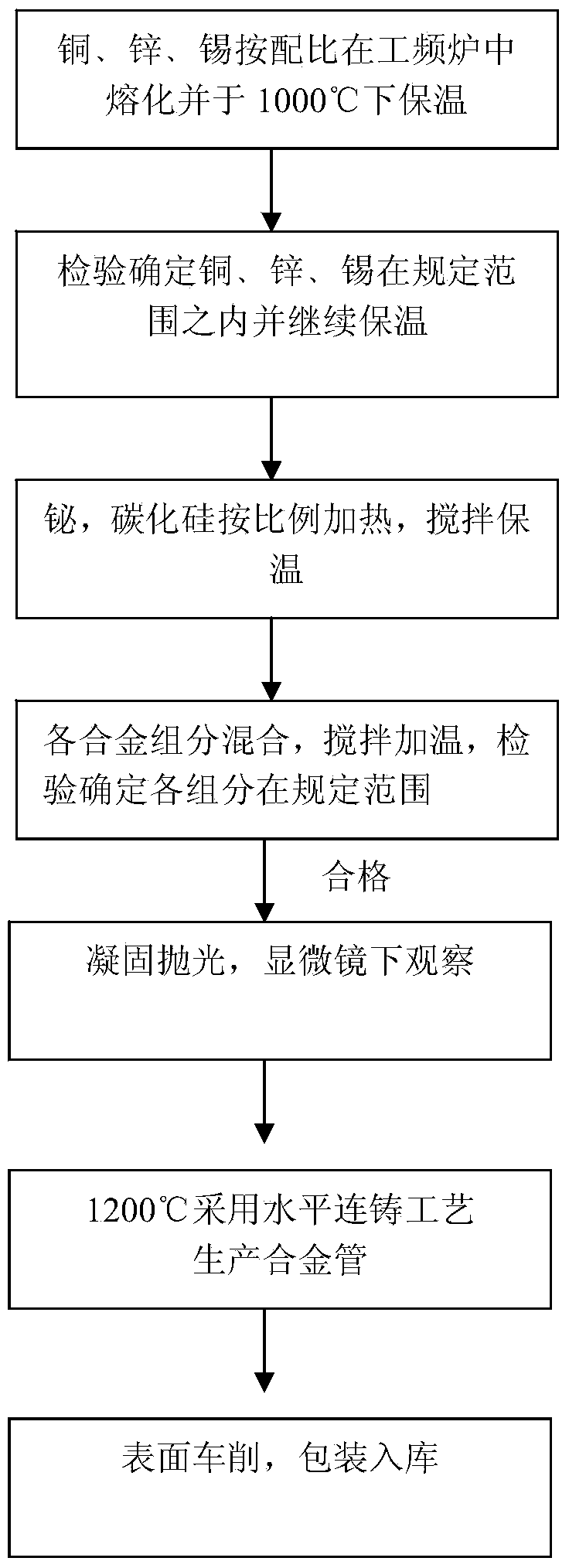

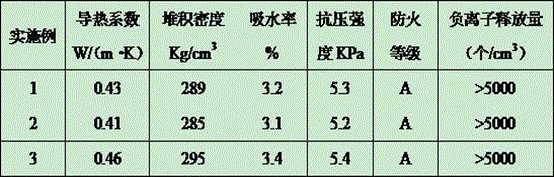

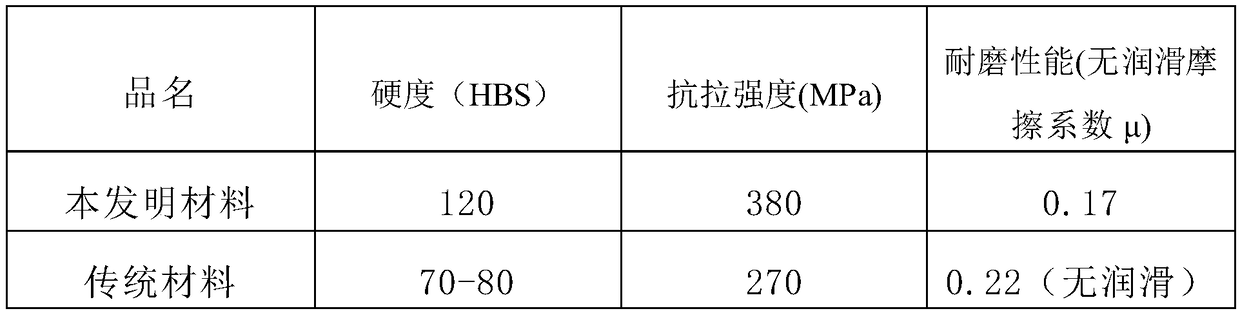

Lead-free environmental-friendly copper-based alloy tube and manufacturing method thereof

ActiveCN103589901AMeet the requirements of environmental performanceImprove cutting performanceWear resistantBismuth

The invention provides a lead-free environmental-friendly copper-based alloy tube and a manufacturing method thereof. The lead-free environmental-friendly copper-based alloy tube provided by the invention consists of the following components by weight: 4-6 percent of zinc, 4-6 percent of tin, 0.5-1.5 percent of bismuth, 1-3 percent of silicon carbide and the balance of copper. In the alloy tube provided by the invention, the bismuth element is adopted to replace a lead element in a conventional copper alloy; a nanoscale silicon carbide material is added; by performance of expanding due to cold and contracting due to heat of bismuth and high toughness and high hardness of the nanoscale silicon carbide material, the lead-free environmental-friendly copper-based alloy tube which completely can replace a tin bronze material containing the lead element is produced. According to the invention, under the condition of not increasing cost, the requirement on environmental-friendly performance of the alloy is met, cutting performance and hardness of the alloy are also further improved, and the lead-free environmental-friendly copper-based alloy tube is suitable for a wear-resistant part at a high temperature (400 DEG C).

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

High-performance building board

The invention discloses a high-performance building board. The high-performance building board is prepared from, by weight, 24-40 parts of cement, 4-5 parts of furnace slag, 2-3 parts of coal gangue, 1-2 parts of tailing sand, 1-2 parts of expanded perlite, 1-2 parts of talcum powder, 2-4 parts of paraffin, 3-5 parts of sulfomethylated phenolic resin, 2-3 parts of AR glass fibers, 2-3 parts of carboxymethyl cellulose, 0.6-1.2 parts of a water reducing agent, 0.4-0.6 part of a foaming agent, 0.4-0.6 part of a foaming regulator, 0.1-0.2 part of a catalyst, 0.3-0.6 part of a crosslinking agent, 0.1-0.2 part of a foam stabilizer, 15-25 parts of glyoxal, 10-20 parts of hydrogen peroxide and 220-260 parts of water. The prepared board is light in weight and excellent in thermal insulation, strength, environment friendliness and fireproof performance, and performance indexes of the board are much higher than national and industrial standard requirements.

Owner:广西南宁桂尔创环保科技有限公司

Environment-friendly building sheet material

InactiveCN106167374AImprove performanceReduce energy consumptionCeramicwarePerformance indexFire prevention

The invention discloses an environment-friendly building sheet material. The environment-friendly building sheet material contains the following raw materials in parts by weight: 20-40 parts of cement, 3-6 parts of construction waste soil, 2-3 parts of sulfomethylated lignite, 1-2 parts of haydite, 1-2 parts of bentonite, 1-2 parts of magnesium borate, 2-4 parts of paraffin, 3-5 parts of sulfomethylated phenol-formaldehyde resin, 2-3 parts of AR glass fibers, 2-3 parts of carboxymethyl cellulose, 0.6-1.2 parts of water reducing agent, 0.4-0.6 part of foamer, 0.4-0.6 part of foaming regulator, 0.1-0.2 part of catalyst, 0.3-0.6 part of cross-linking agent, 0.1-0.2 part of foam stabilizer, 15-25 parts of glyoxal, 10-20 parts of hydrogen peroxide and 200-250 parts of water. The sheet material disclosed by the invention has excellent light weight, heat preservation, fire prevention, high strength and environment-friendliness properties, and performance indexes of the sheet material outclass those in national and industry standard requirements.

Owner:广西南宁桂尔创环保科技有限公司

A kind of improved environmental protection building board and preparation method thereof

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 3 to 12 parts of gangue, 2 to 8 parts of paraffin, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 6 to 14 parts of a glass fiber, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:GAOYOU MINGZENG BIOLOGICAL PROD CO LTD

Alloy pipe made of novel environment-friendly lead-free alloy material and used for ocean engineering

The invention provides an alloy pipe made of a novel environment-friendly lead-free alloy material and used for ocean engineering. The alloy pipe comprises, by weight percentage, 1% to 4.5% of zinc (Zn), 6% to 8% of tin (Sn), 0.5% to 1.5% of silicon (Si) and the balance copper (Cu). By the adoption of the alloy pipe made of the novel environment-friendly lead-free alloy material and used for ocean engineering, the traditional lead element is replaced with the silicon element, silicon, tin, zinc and copper are smelted at the proper temperature according to a certain proportion, blank ingots are continuously cast, an extruding machine is used for extrusion so that the alloy pipe capable of replacing a tin bronze pipe and containing the lead element can be produced, and under the condition that cost is not increased, the mechanical properties such as cuttings of existing tin bronze are reserved, and the requirement for the environment-friendly performance is met as well.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

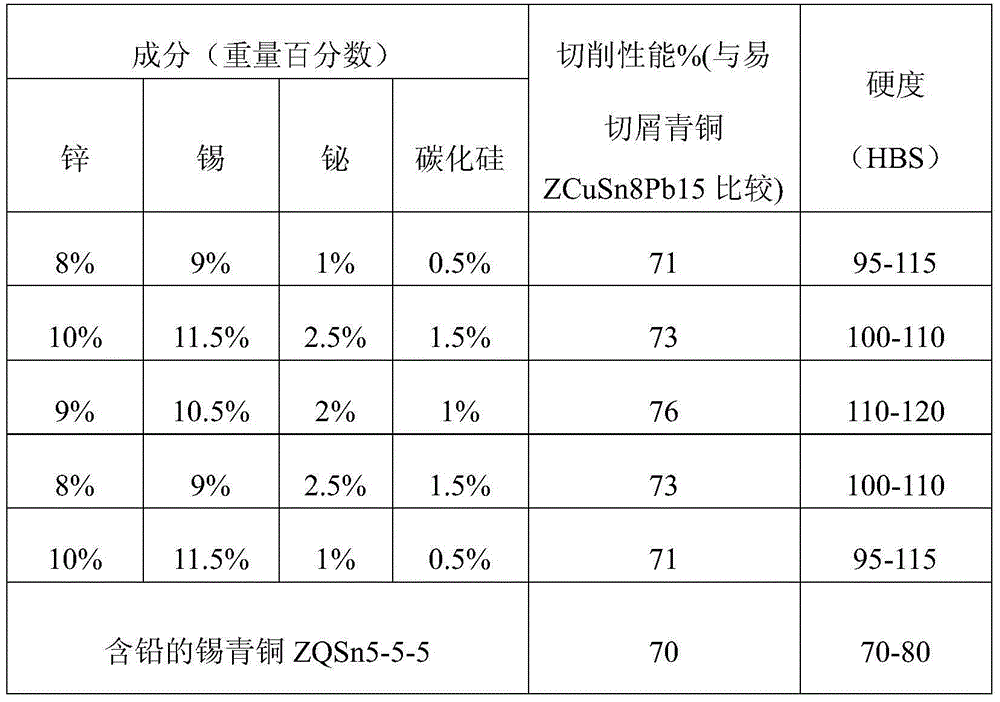

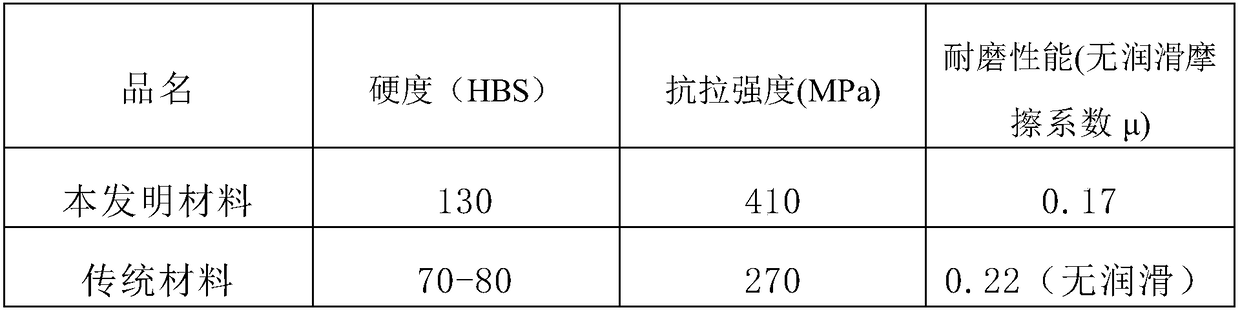

Lead-free environment-friendly copper-based alloy bar and preparation method thereof

ActiveCN103555992AMeet the requirements of environmental performanceImprove cutting performanceWear resistantHardness

The invention provides a lead-free environment-friendly copper-based alloy bar and a preparation method thereof. The lead-free environment-friendly copper-based alloy bar comprises the following components in percentage by weight: 8%-10% of zinc, 9%-11.5% of tin, 1%-2.5% of bismuth, 0.5%-1.5% of silicon carbide and the balance of copper. According to the alloy bar, the bismuth element replaces the lead element in the traditional copper alloy, and a nanoscale silicon carbide material is added, and the material entirely capable of replacing tin bronze containing lead element can be produced through the cold contraction and heat expansion of bismuth and the high toughness and high hardness of the nanoscale silicon carbide material. Under the condition of not increasing the cost, the cutting performance and hardness of the alloy can be further improved while the environment-friendly performance requirement of the alloy can be met, and the lead-free environment-friendly copper-based alloy bar is suitable for wear-resistant parts under high-temperature (400 DEG C) situation.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Improved environmentally friendly building board material

The invention discloses an improved environmentally friendly building board material. The improved environmentally friendly building board material is prepared from, by weight, 25-35 parts of cement, 4-5 parts of furnace slag, 2-3 parts of pulverized fuel ash, 1-2 parts of common sand, 1-2 parts of bentonite, 1-2 parts of magnesium borate, 2-4 parts of paraffin wax, 3-5 parts of sulfonated-pheno-formoldehyde resin, 2-3 parts of AR glass fiber, 2-3 parts of carboxymethyl cellulose, 0.6-1.2 parts of water reducing agent, 0.4-0.6 part of foaming agent, 0.4-0.6 part of foaming regulator, 0.1-0.2 part of catalyst, 0.3-0.6 part of crosslinking agent, 0.1-0.2 parts of foam stabilizing agent, 20-24 parts of glyoxal, 12-18 parts of hydrogen peroxide and 210-240 parts of water. The boards prepared by the material have excellent light-weight, heat-preservation, fireproof, high-strength and environmental-protection properties, and the properties of the boards are much higher than the requirements of the national and industry standards.

Owner:广西南宁桂尔创环保科技有限公司

Continuous casting alloy material for bearing bush and preparation method thereof

InactiveCN107460364AMeet the requirements of environmental performanceImprove cutting performanceBearing componentsWear resistantBismuth

The invention relates to a continuous casting alloy material for a bearing bush and a preparation method thereof. The continuous casting alloy material for the bearing bush is prepared from, by weight, 1.5%-3.5% of zinc, 3.5%-7.5% of tin, 0.3%-1.0% of bismuth, 0.15%-0.5% of silicon carbide, 0.1%-0.5% of aluminum oxide, and the balance copper. The preparation method of the continuous casting alloy material for the bearing bush comprises the steps of in-batch smelting, stirring, inspecting and the like. The continuous casting alloy material for the bearing bush does not contain lead, the cutting performance and the hardness of the alloy are further improved while the requirement on the environmental friendliness of the alloy is met on the condition that the cost is not increased, and therefore the continuous casting alloy material is more suitable for wear-resistant parts used at high temperature (400 DEG C).

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Manufacturing process of low volatile organic compound (VOC) polyurethane automobile instrument board

InactiveCN109535381AReduce volatilityImprove environmental performanceVegetable oilAutomobile market

The invention belongs to the technical field of high polymer materials, and particularly relates to a manufacturing process of a low volatile organic compound (VOC) polyurethane automobile instrumentboard. The polyurethane soft automobile instrument board is manufactured by taking a material A and a material B as raw materials, wherein the material A is composed of polyether polyol, vegetable oil, a tertiary amine catalyst, silicon oil, a chain extender and water, and the material B is composed of liquefied methylene diphenyl diisocyanate (MDI) and crude MDI. The low-volatile and reaction-type raw materials are selected for the polyurethane composition provided by the invention. The production method is simple, is easy to implement, and has the advantages of environmental friendliness, nopollution and the like. The content of volatile organic compounds of the prepared instrument board is reduced on the premise that other performance is not influence, and requirements of a medium-high-end automobile market on polyurethane low-VOC automobile instrument boards are met.

Owner:SHANGHAI INST OF TECH

Novel environment-friendly silicon-containing alloy material tube and preparation method thereof

InactiveCN107619965AMeet the requirements of environmental performanceRetain mechanical properties such as chipsTitaniumZinc

The invention provides a novel environment-friendly silicon-containing alloy material tube and a preparation method thereof. The alloy material tube is composed of, by the total weight of the alloy material tube, 1-3% of zinc, 1-3% of tin, 0.5-2.5% of aluminum, 0.05-0.5% of stibium, 0.5-1% of silicon, 0-1% of titanium and the balance copper. The traditional lead element is replaced with the silicon element, zinc, tin, aluminum, stibium, silicon and copper are blended at a proper temperature according to a certain component ratio, by continuously casting a blank tube, a tin bronze tube containing the lead element can be completely replaced with the tube extruded through an extruding machine, thus, under the condition that the cost is not increased, the mechanical properties such as turningof existing tin bronze are reserved, and the requirement for the environmental protection performance of alloy is met.

Owner:绵阳旺通科技有限公司

Continuous casting copper alloy material for abrasion-resistant gear and manufacturing method thereof

InactiveCN108642319AMeet the requirements of environmental performanceImprove cutting performanceHardnessZinc

The invention discloses a continuous casting copper alloy material for an abrasion-resistant gear and a manufacturing method thereof. The continuous casting copper alloy material for the abrasion-resistant gear comprises, by mass: 1-2% of zinc, 2-3% of tin, 2-3% of bismuth, 0.5-1% of antimony, 0.4-0.6% of silicon carbide, 0.4-0.7% of aluminum oxide, and the balance copper. According to the continuous casting copper alloy material for the abrasion-resistant gear, the cutting performance and hardness of an alloy are further improved while the requirement for the environmental protection performance of the alloy is met on the premise that the cost is not increased; and the continuous casting copper alloy material is more suitable for abrasion-resistant spare parts under high temperature (400DEG C).

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Porous silicon electrode for lithium ion battery based on 3D printing technology and its preparation method

ActiveCN110350148BLow preparation temperatureSimple processElectrode manufacturing processesSecondary cellsSilicon electrodeLithium-ion battery

The invention discloses a lithium-ion battery porous silicon electrode based on 3D printing technology, which consists of the following components according to the mass ratio: solvent I 10%-15%, solvent II 25%-35%, pore-forming agent 4%-8 %, 45% to 55% of electrode active materials, 2% to 4% of conductive enhancers, and 2% of binders, totaling 100%. The invention also discloses a method for preparing the above-mentioned porous silicon electrode of lithium ion battery based on 3D printing technology. The porous silicon electrode of the lithium ion battery prepared by the invention based on the 3D printing technology has suitable porosity, excellent cycle stability, excellent electrical conductivity, simple preparation process, and meets environmental protection requirements.

Owner:高能数造(西安)技术有限公司

Building board

InactiveCN107324754ALow energy consumptionImprove performanceHeat proofingParaffin waxSodium carboxymethylcellulose

The invention relates to a building board. The building board is characterized by comprising, by weight, 30-40 parts of cement, 5-8 parts of slag, 3-5 parts of fly ash, 2-4 parts of straw powder, 2-3 parts of bentonite, 4-5 parts of magnesia cement, 5-6 parts of paraffin wax, 6-7 parts of sulfomethylated phenolic resin, 4-5 parts of AR glass fibers, 4-5 parts of carboxymethyl cellulose, 2-3 parts of water reducing agent, 1-2 parts of foaming agent, 1-2 parts of foaming control agent, 0.2-0.4 part of catalyst, 0.6-1 part of cross-linking agent, 0.2-0.4 part of foam stabilizer, 30-35 parts of glyoxal, 20-25 parts of hydrogen peroxide and 180-250 parts of water.

Owner:南通成山高分子材料有限公司

Preparation method of low VOC polyurethane automobile steering wheel

InactiveCN109575231AReduce volatilityImprove environmental performanceEnvironmental resistanceSteering wheel

The invention belongs to the technical field of high polymer materials, in particular to a preparation method of a low VOC polyurethane automobile steering wheel. The polyurethane automobile steeringwheel is prepared and processed from materials A and B, wherein, the material A consists of polyether polyol, vegetable oil, amine catalysts, hydroxyl silicone oil, a chain extender and a foaming agent; and the material B consists of liquefied MDI and crude MDI. The method selects low volatilization and reactive raw materials, and the production method is not only simple and easy to implement, butalso has the advantages of environmental protection, no pollution and the like. The prepared steering wheel reduces the content of volatile organic compounds on the premise of not affecting other performances of the polyurethane steering wheel for automobiles, and can meet the requirements of the middle and high-end automobile market on the low VOC polyurethane steering wheels.

Owner:SHANGHAI INST OF TECH

A kind of environmental protection building plate and preparation method thereof

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 3 to 12 parts of gangue, 4 to 15 parts of fly ash, 2 to 8 parts of paraffin, 7 to 13 parts of urea, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:南通和鼎智能科技股份有限公司

A kind of aluminum base-steel bimetal bearing material and its preparation process

ActiveCN105626695BMeet the requirements of environmental performanceImprove carrying capacityBearing componentsAlloyPollution

The invention belongs to the technical field of bearing pad materials, and specifically discloses an aluminum-based-steel bimetallic bearing pad material and a preparation process thereof. The material is composed of an aluminum covering layer, an aluminum-based alloy layer, an aluminum transition layer and a low-carbon steel layer; among them, the aluminum-based alloy layer is an endogenous TiB2 with endogenous TiB2 particles as a reinforcement and an aluminum-tin-copper alloy as a matrix alloy. Particle-reinforced aluminum-tin-copper alloy. The preparation method comprises the following steps: (1) preparing materials; (2) preparing an aluminum-based alloy layer; (3) rolling with aluminum cladding; (4) manufacturing steel strips; (5) cold rolling and compounding. The interface bonding strength between the aluminum base alloy layer and the steel plate of the aluminum base-steel bimetallic bearing material of the present invention is high, the bearing capacity of the aluminum base-steel bimetallic bearing material is strong and the anti-friction property is good, the bearing pad works stably, has a long service life, and produces Low cost, environmental protection and no pollution.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

An environmentally friendly wall decoration diatom mud coating

The invention discloses an environment-friendly wall decoration diatom mud coating, which comprises the following raw materials in percentage by weight: 15% of ash calcium powder, 10% of kaolin, 10% of talc, 20% of heavy calcium carbonate, and 10% of quartz powder , 15% cement, 10% silica fume, 0.8% cellulose, 3% binder, 1.5% bentonite, 0.15% sodium powder, 0.15% superplasticizer, 4.4% super diatomaceous earth. Beneficial effects of the present invention: the design is reasonable, it is beneficial to avoid the inclusion of rubber, thereby avoiding the problem of formaldehyde, and it is also beneficial to reduce the cost of production and transportation, and at the same time, it can better reduce the problem of radiation itself during use.

Owner:杭州范洛环保科技有限公司

Environment-friendly building board and preparation method thereof

The invention specifically relates to a lightweight, heat-preserving, high-strength and environment-friendly building board and a preparation method thereof, belonging to the field of building materials. The environment-friendly building board is prepared from the following components by weight: 5 to 10 parts of cement, 4 to 15 parts of gangue, 2 to 8 parts of paraffin, 7 to 13 parts of urea, 4 to 8 parts of sulfomethyl phenol formaldehyde resin, 6 to 14 parts of a glass fiber, 8 to 15 parts of bentonite, 3 to 9 parts of methyl cellulose, 1 to 5 parts of mullite, 2 to 5 parts of Chinese medical stone, 2 to 5 parts of zeolite, 1 to 6 parts of sulfomethyl lignite, 4 to 15 parts of hydroxyethyl cellulose and 0.5 to 1.5 parts of a foaming agent. The board provided by the invention has good performances like lightweight, heat preservation, fire resistance and high strength, and the performance index of the board is much higher than national and industrial standard requests in China.

Owner:SHENZHEN KANGYA ECOLOGICAL ENVIRONMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com