Environment-friendly building sheet material

A technology for building panels and environmental protection, applied in the field of building materials preparation, can solve the problems that building panels cannot meet the performance requirements of light weight, heat preservation, high strength, environmental protection, etc., and achieve the effect of good performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

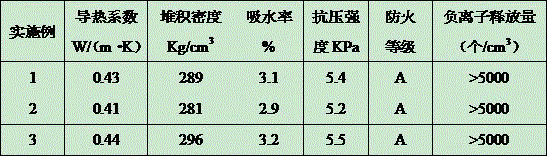

Examples

preparation example Construction

[0033] The preparation method of the environmental protection building board comprises the following steps:

[0034] S1: Stir cement, hydrogen peroxide, glyoxal and water evenly at a speed of 100-300r / min to prepare a slurry;

[0035] S2: Combine construction waste soil, sulfomethyl lignite, ceramsite, bentonite, magnesium borate, paraffin, sulfomethyl phenolic resin, AR glass fiber, carboxymethyl cellulose, water reducer, foaming agent, foam The conditioner, catalyst, crosslinking agent and foam stabilizer are stirred for 3-4 hours at a temperature of 200-300 ° C and a rotation speed of 60-100 r / min to prepare a foam liquid;

[0036] S3: Add the foam liquid prepared in step S2 to the slurry prepared in step S1, and stir evenly at a rotating speed of 200-300r / min to obtain a foaming material;

[0037] S4: Pour the foamed material prepared in step S3 into a mold, shake and smooth it, and apply a pressure of 0.9-0.95 MPa to the foamed material for molding for 12-15 seconds, and...

Embodiment 1

[0041] An environment-friendly building board, comprising the following raw materials in parts by weight: 30 parts of cement, 5 parts of construction waste soil, 2.5 parts of sulfomethyl lignite, 1.6 parts of ceramsite, 1.5 parts of bentonite, 1.5 parts of magnesium borate, paraffin wax 3 parts, 4 parts of sulfomethyl phenolic resin, 2.5 parts of AR glass fiber, 2.5 parts of carboxymethyl cellulose, 0.9 parts of water reducer, 0.5 parts of foaming agent, 0.5 parts of foam regulator, 0.1 part of catalyst, crosslinking 0.5 parts of agent, 0.1 parts of foam stabilizer, 20 parts of glyoxal, 15 parts of hydrogen peroxide, and 230 parts of water;

[0042] The water reducer is a polycarboxylate water reducer;

[0043] Described whipping agent is azodicarbonamide;

[0044] The foam regulator is an acrylate foam regulator;

[0045] The catalyst is stannous octoate;

[0046] Described linking agent is dicumyl peroxide;

[0047] The foam stabilizer is silicone amide;

[0048] The pr...

Embodiment 2

[0055] An environment-friendly building board, comprising the following raw materials in parts by weight: 20 parts of cement, 3 parts of construction waste soil, 2 parts of sulfomethyl lignite, 1 part of ceramsite, 1 part of bentonite, 1 part of magnesium borate, paraffin wax 2 parts, 3 parts of sulfomethyl phenolic resin, 2 parts of AR glass fiber, 2 parts of carboxymethyl cellulose, 0.6 parts of water reducer, 0.4 parts of foaming agent, 0.4 parts of foam regulator, 0.1 part of catalyst, crosslinking 0.3 parts of agent, 0.1 parts of foam stabilizer, 15 parts of glyoxal, 10 parts of hydrogen peroxide, and 200 parts of water;

[0056] The water reducer is a polycarboxylate water reducer;

[0057] Described whipping agent is azodicarbonamide;

[0058] The foam regulator is an acrylate foam regulator;

[0059] The catalyst is triethylenediamine hexahydrate;

[0060] Described linking agent is dicumyl peroxide;

[0061] The foam stabilizer is silicone amide;

[0062] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com