Preparation method of low VOC polyurethane automobile steering wheel

A technology of steering wheel and polyurethane, which is applied in the field of preparation of low-VOC polyurethane automobile steering wheel, can solve the problems of high price of steering wheel, and achieve the effect of no ozone destruction effect, low production cost, and reduced volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

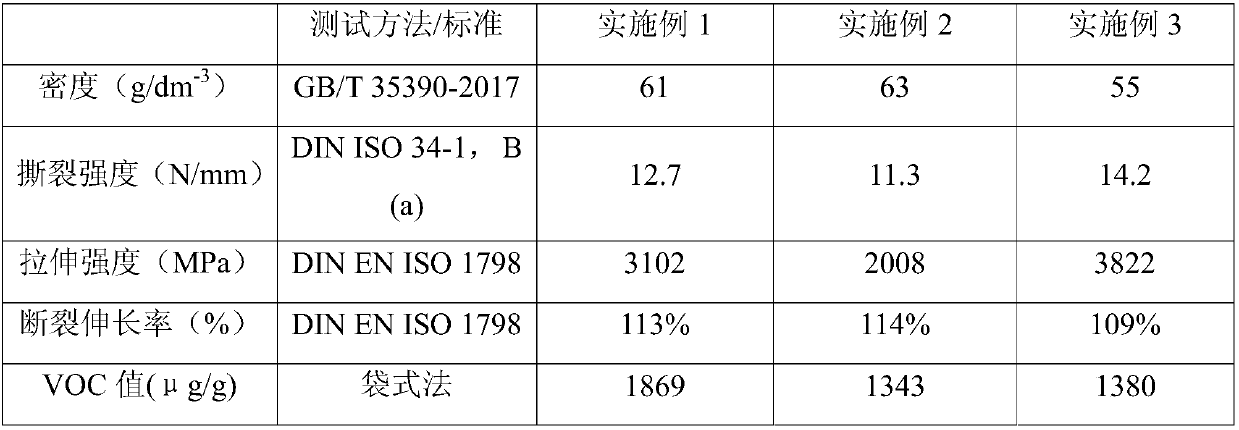

Examples

Embodiment 1

[0027] ① Preparation of material A: Add 0.1 kg of triethylenediamine, 2 kg of water, 1 kg of 106 hydroxy silicone oil from Jiaxing Kerui Silicone Co., Ltd., and 1 kg of propylene glycol to 91 kg of polyether polyol CHE-828D from Changhua Company, and control Rotate at 50-80 rpm, stir at room temperature for 50 minutes, and you can get material A;

[0028] ②Preparation of material B: join Wanhua company 6928 has a mass of 15.5kg, added to Wanhua’s MDI-50 has a mass of 50kg. Stir the two at room temperature for 40 minutes, and control the speed at 30-50 rpm to obtain material B;

[0029] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machine;

[0030] ④Preparation of the steering wheel: use a foaming machine to mix the above materials A and B evenly in the mixing zone of the pouring machine mixing head, and cast them into shape; demould, cut a...

Embodiment 2

[0032] ① Preparation of material A: Add 1kg of jatropha oil, 0.1kg of triethylenediamine, 2kg of water, and 1kg of 106 hydroxy silicone oil from Jiaxing Kerui Silicone Co., Ltd. to 90kg of polyether polyol CHE-828D from Changhua Company , add 1 kg of propylene glycol, control the speed at 50-80 rpm, and stir at room temperature for 50 minutes to obtain material A;

[0033] ②Preparation of material B: join Wanhua company 6928 has a mass of 15.5kg, added to Wanhua’s MDI-50 has a mass of 50kg. Stir the two at room temperature for 40 minutes, and control the speed at 30-50 rpm to obtain material B;

[0034] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machine;

[0035] ④Preparation of the steering wheel: use a foaming machine to mix the above materials A and B evenly in the mixing zone of the pouring machine mixing head, and cast them into sha...

Embodiment 3

[0037] ① Preparation of material A: Add 95kg of polyether polyol CHE-828D from Changhua Company, 0.5kg of soybean oil, 0.2kg of triethylenediamine, 2kg of water, 2kg of 106 hydroxy silicone oil from Jiaxing Kerui Silicone Co., Ltd., Add 2 kg of propylene glycol, control the rotation speed at 50-80 rpm, and stir at room temperature for 50 minutes to obtain material A;

[0038] ②Preparation of material B: add 19kg of Wanhua company 6928, add 45kg of Wanhua company's MDI-50. Stir the two at room temperature for 40 minutes, and control the speed at 30-50 rpm to obtain material B;

[0039] ③Preparation of raw materials: Put material A into the raw material barrel of group A of the foaming machine; put material B into the raw material barrel of group B of the foaming machine;

[0040] ④Preparation of the steering wheel: use a foaming machine to mix the above materials A and B evenly in the mixing zone of the pouring machine mixing head, and cast them into shape; demould, cut an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com