Lithium ion battery porous silicon electrode based on 3D printing technology

A lithium-ion battery, 3D printing technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of high manufacturing cost and complex manufacturing process, and achieve the effects of low cost, simple manufacturing process and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

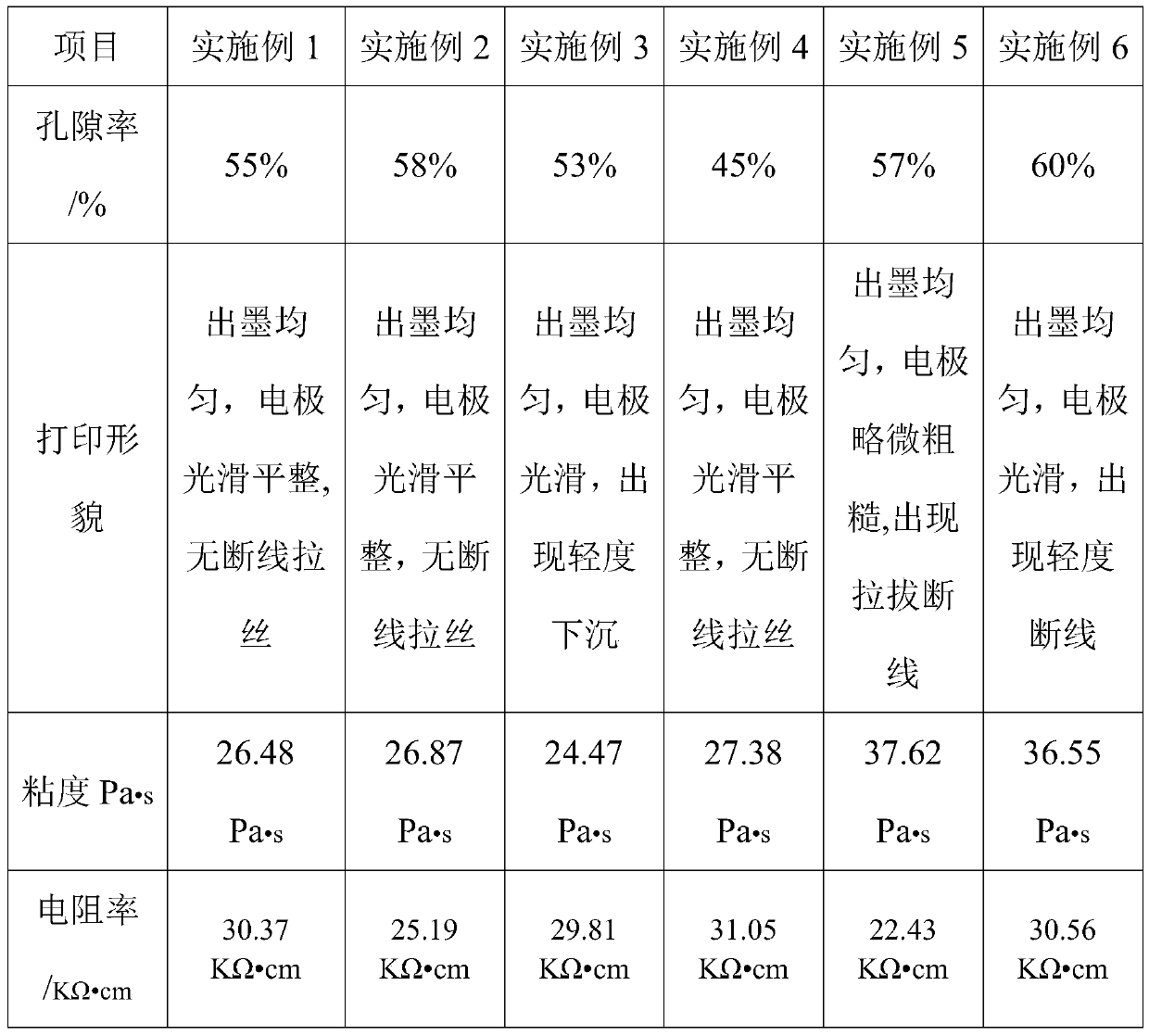

Examples

Embodiment 1

[0038] Step 1, weigh the following components with an electronic balance according to mass percentage, solvent I 10% (wherein the mass percentage of polyethylene in xylene is 2wt%), solvent II 30% (deionized water: ethylene glycol: glycerol = 96:2:2), pore-forming agent ammonium bicarbonate 6%, elemental silicon 50% of electrode active material, conduction enhancer 2-20nm carbon nanotube 2%, binder carboxymethyl cellulose 2%, total 100%;

[0039] Step 2. Dry-mill the ammonium bicarbonate of micron-scale and nano-scale size in a ball mill tank with a ball-to-material ratio of 7:1 for 2 hours, mix well, and obtain particle A for use;

[0040] Step 3. Slowly add the particle A obtained in step 2 to the xylene solution of solvent I polyethylene, and place it on a magnetic stirrer for 25 minutes, then disperse it by ultrasonic oscillation for 5 minutes, then centrifuge it in a centrifuge for 5 minutes, and then dry it in a vacuum. oven at 50°C to a semi-dry state to obtain mixture...

Embodiment 2

[0046] Step 1, weigh the following components with an electronic balance according to mass percentage, solvent I 15% (wherein the mass percentage of polyethylene in xylene is 5wt%), solvent II 25% (deionized water: ethylene glycol: glycerol = 96:2:2), pore-forming agent ammonium chloride 5%, elemental silicon 50% of electrode active material, conduction enhancer 2-20nm diameter carbon nanotube 3%, binder carboxymethyl cellulose 2%, total 100%;

[0047] Step 2. Dry-mill ammonium chloride in micron-scale and nano-scale in a ball mill tank with a ball-to-material ratio of 7:1 for 2 hours, mix evenly, and obtain particle A for use;

[0048] Step 3. Slowly add the particle A obtained in step 2 to the xylene solution of solvent I polyethylene, and place it on a magnetic stirrer for 15 minutes, then disperse it by ultrasonic oscillation for 10 minutes, then centrifuge it in a centrifuge for 5 minutes, and then dry it in a vacuum. oven at 50°C to a semi-dry state to obtain mixture B;...

Embodiment 3

[0054] Step 1, weigh the following components with an electronic balance according to mass percentage, solvent I 10% (wherein the mass percentage of polyethylene in xylene is 10wt%), solvent II 35% (deionized water: ethylene glycol: glycerol = 96:2:2), pore-forming agent ammonium chloride 6%, electrode active material elemental silicon 45%, conductivity enhancer 2-20nm carbon nanotubes, binder carboxymethyl cellulose 2%, total 100%;

[0055] Step 2. Dry-mill ammonium nitrate in a ball mill tank with a ball-to-material ratio of 7:1 for 2.5 hours, mix evenly, and obtain particle A for use;

[0056] Step 3. Slowly add the particle A obtained in step 2 to the xylene solution of solvent I polyethylene, and place it in a magnetic stirrer for 45 minutes, then disperse it by ultrasonic oscillation for 10 minutes, then centrifuge it in a centrifuge for 10 minutes, and then dry it in a vacuum. oven at 50°C to a semi-dry state to obtain mixture B;

[0057] Step 4. Add carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com