Environment-friendly building board and preparation method thereof

A technology for building panels and environmental protection, applied in the field of environmentally friendly building panels and its preparation, can solve the problems that building panels cannot meet environmental protection and light weight, and achieve good performance, lower temperature and energy consumption, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

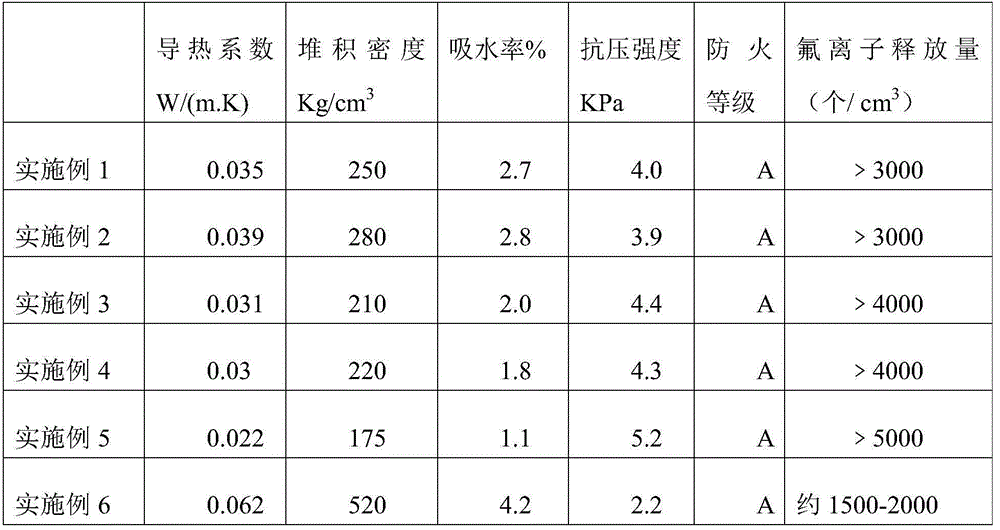

Examples

Embodiment 1

[0027] The environmentally friendly building board described in this embodiment is prepared from the following components in parts by weight:

[0028] Cement 5kg, coal gangue 15kg, paraffin 8kg, urea 7kg, sulfomethyl phenolic resin 8kg, glass fiber 6kg, bentonite 15kg, methyl cellulose 3kg, mullite 5kg, medical stone 2kg, zeolite 5kg, sulfomethyl lignite 1kg, hydroxyethyl cellulose 15 and foaming agent 0.5kg.

[0029] The environmentally friendly building panels described in this example are prepared by the following steps:

[0030] (1) Get described cement, gangue, mullite, medical stone, bentonite, zeolite, sulfomethyl lignite and foaming agent of selected weight 1 / 4 according to selected weight, mix and sieve, spare;

[0031] (2) Take the paraffin, urea, sulfomethyl phenolic resin, glass fiber, methyl cellulose, hydroxyethyl cellulose and the remaining foaming agent according to the selected parts by weight, mix well and heat to 110°C to carry out Low temperature foaming...

Embodiment 2

[0036] The environmentally friendly building board described in this embodiment is prepared from the following components in parts by weight:

[0037] Cement 10kg, coal gangue 4kg, paraffin 2kg, urea 13kg, sulfomethyl phenolic resin 4kg, glass fiber 14kg, bentonite 8kg, methyl cellulose 9kg, mullite 1kg, medical stone 5kg, zeolite 2kg, sulfomethyl lignite 6kg, hydroxyethyl cellulose 4kg and foaming agent 1.5kg.

[0038] The environmentally friendly building panels described in this example are prepared by the following steps:

[0039] (1) Get the blowing agent of described cement, coal gangue, mullite, medical stone, bentonite, zeolite, sulfomethyl lignite and 1 / 3 of selected parts by weight according to the selected parts by weight, mix well And sieve, set aside;

[0040] (2) Take the paraffin, urea, sulfomethyl phenolic resin, glass fiber, methyl cellulose, hydroxyethyl cellulose and the remaining foaming agent according to the selected parts by weight, mix well and heat t...

Embodiment 3

[0045] The environmentally friendly building board described in this embodiment is prepared from the following components in parts by weight:

[0046] Cement 6kg, coal gangue 10kg, paraffin 6kg, urea 9kg, sulfomethyl phenolic resin 7kg, glass fiber 9kg, bentonite 13kg, methyl cellulose 5kg, mullite 4g, medical stone 3kg, zeolite 4kg, sulfomethyl lignite 2kg, 11kg of hydroxyethyl cellulose and 0.7kg of blowing agent.

[0047] The environmentally friendly building panels described in this example are prepared by the following steps:

[0048] (1) Get the foaming agent of described cement, coal gangue, mullite, medical stone, bentonite, zeolite, sulfomethyl lignite and selected parts by weight according to the selected weight, mix and sieve ,spare;

[0049](2) Take the paraffin wax, urea, sulfomethyl phenolic resin, glass fiber, methyl cellulose, hydroxyethyl cellulose and the remaining foaming agent according to the selected weight, mix and heat to 110 ° C for low temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com