Laywire combination structure for concert buildings

A technology for concrete construction and composite structure, which is applied to building components, building structures, buildings, etc., and can solve the problems of inconvenient vibration, inability to pour and compact concrete, and unstable internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment.

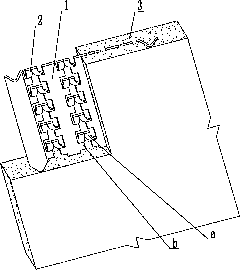

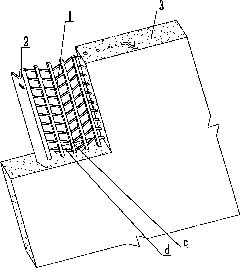

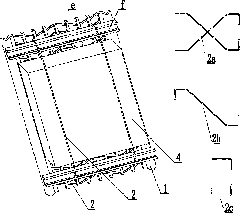

[0047] In the embodiment of the present invention, the composite structure of concrete building formwork and mesh includes steel mesh 1, which is characterized in that the steel mesh 1 is provided with a positioning connection device 2, self-compacting concrete 3 is poured on the steel mesh 1, self-compacting concrete 3 It is consolidated and hardened with the expanded metal mesh 1 to form a whole. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, such as figure 1 As shown, self-compacting concrete 3 is poured around the single expanded metal mesh 1, and a positioning connection device 2 is arranged on the expanded metal mesh 1. The positioning connecting device 2 includes two parts a and b, and part a is two parts cut from the steel plate A piece of steel, the two pieces of broken steel a are welded together, or they can be completely integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com