Sludge ceramsite and ceramsite enhanced foam concrete self-insulation building block and preparation method of building block

A self-insulating block and sludge ceramsite technology, which is applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of unsatisfactory thermal insulation effect, high density, and high quality of lightweight wall materials. The effect of excellent thermal insulation performance, light density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

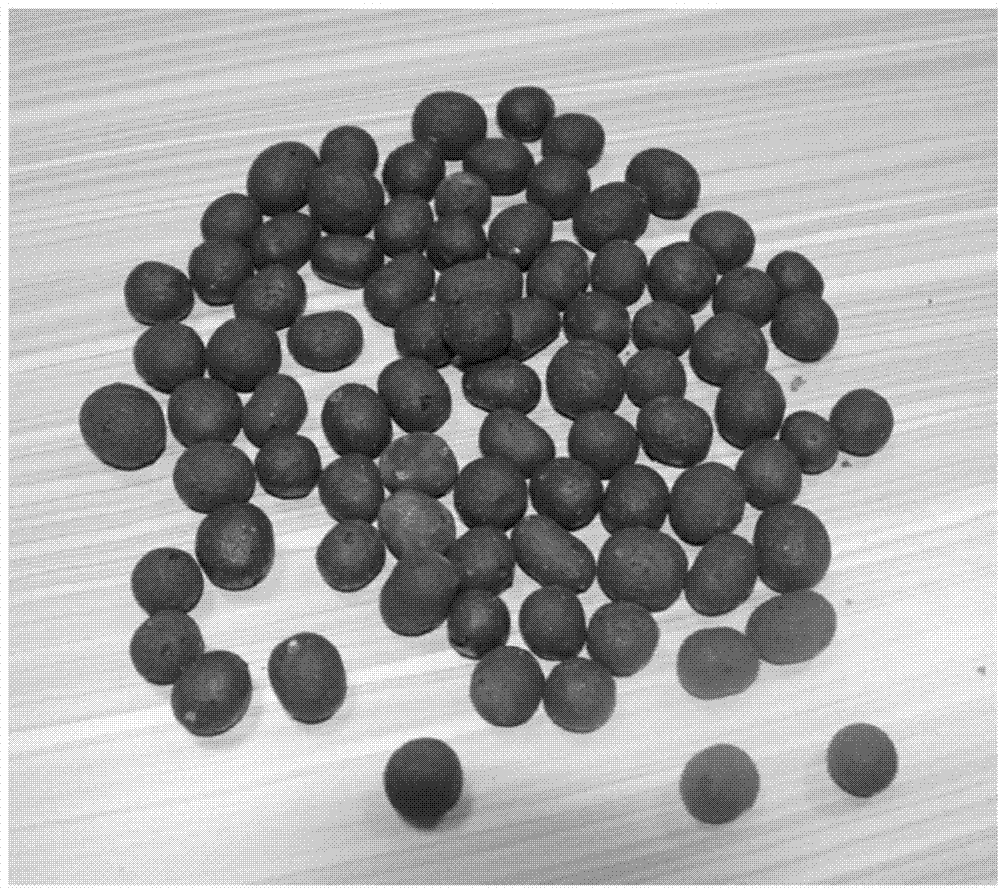

[0054] Dry the river sludge with a water content of about 70% to a water content of 40%, take 50 parts, and then mix with 10 parts of construction waste (with a water content of about 30%) and 80 mesh fly ash (water content) with an average particle size of about 3mm. rate of about 30%), 10 parts of 80-mesh stone powder (moisture content of about 25%) are mixed, after humidification and drying treatment, the moisture content of the mixed material is controlled to about 40%, and it is granulated by a granulator to produce Small particles, small particles are directly fed from the top of the ceramsite rotary kiln, and the small particles fall into the ceramsite rotary kiln from the high-speed rotor in an instant, and the small particles fall through the 1200 ℃ high temperature zone in the kiln, immediately forming boiling and evaporating water, After expansion, the expanded particles are rotated out of the ceramsite rotary kiln to form a brown sludge ceramsite with a shape close ...

Embodiment 2

[0075] Dry the industrial wastewater sludge with a moisture content of about 50% to a moisture content of 40%, take 40 parts, then 15 parts of 80 mesh fly ash (moisture content about 30%), 80 mesh stone powder (moisture content of about 25%) After mixing 15 parts, through humidification and drying treatment, the moisture content of the mixture is controlled to about 35%, and it is granulated by a granulator to make small particles. The small particles are directly fed from the top of the ceramsite rotary kiln, and the small particles are from The high-speed rotating rotor instantly falls into the ceramsite rotary kiln, and the small particles fall through the 1150°C high temperature zone in the kiln, immediately boiling and evaporating water, expanding, and the expanded particles are rotated out of the ceramsite rotary kiln, forming It is brown and the shape is close to spherical sludge ceramsite. Characterization of the prepared sludge ceramsite sample: the density is 300.2kg...

Embodiment 3

[0077] Dry the mud with a moisture content of about 60% to a moisture content of 40%, take 50 parts, and mix it with 20 parts of 80-mesh fly ash (with a moisture content of about 30%), and then control the mixture by humidifying and drying. The moisture content of the material is controlled at about 40%, and it is granulated by a granulator to make small particles. The small particles are directly fed from the top of the ceramsite rotary kiln, and the small particles instantly fall into the ceramsite rotary kiln from the high-speed rotor. Falling through the 1250°C high temperature zone in the kiln, boiling and evaporating water are formed immediately, and the expanded particles are rotated out of the ceramsite rotary kiln, forming brown sludge ceramsite with a shape close to a spherical shape. Characterization of the prepared river sludge ceramsite sample: the density is 289.7kg / m 3 , the cylinder compressive strength is 0.32MPa, and the particle size distribution is in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com