Novel lead-free environmental-friendly copper-based alloy material and manufacturing method thereof

A technology of copper-based alloy and manufacturing method, which is applied in the manufacture of new alloy materials and the field of lead-free and environmentally friendly copper-based alloy new materials, which can solve the problems of lead hazards and reduce the machinability of new alloy materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

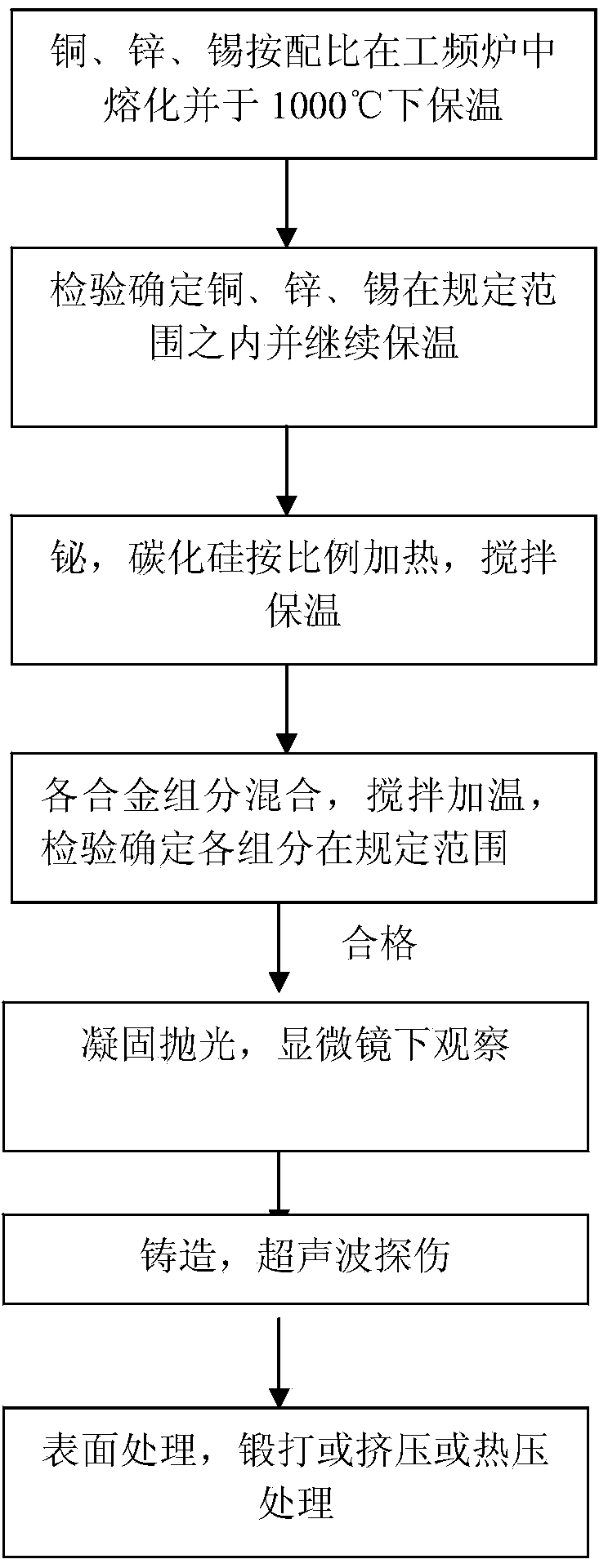

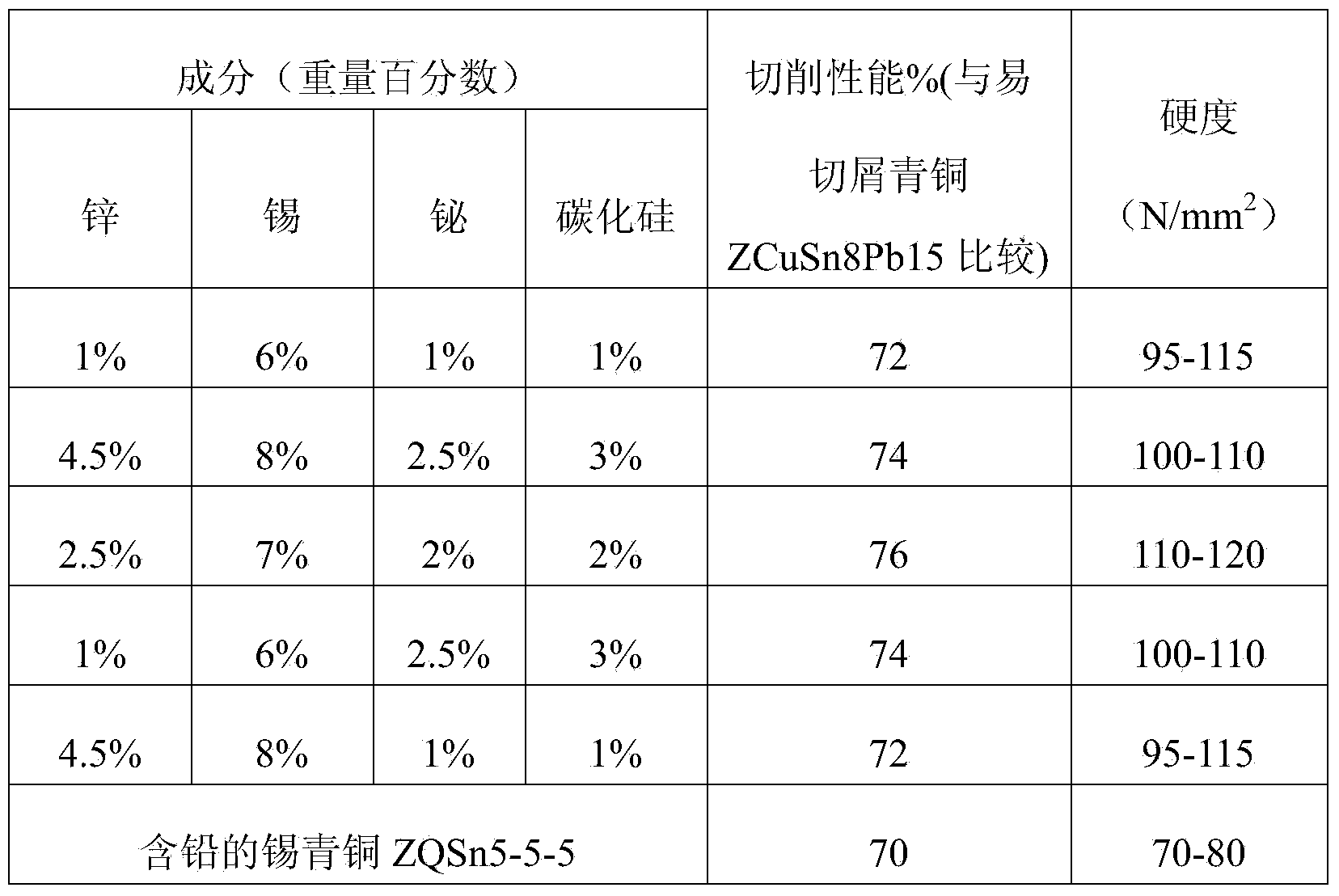

[0026] A new lead-free environment-friendly copper-based alloy material is composed of the following components in weight percentage: 1% zinc, 6% tin, 1% bismuth, 1% silicon carbide, and the balance is copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0027] Put copper, tin and zinc in the power frequency electric furnace according to the weight percentage ratio mentioned above, heat it to 1100°C and melt it completely, then keep it warm to 1000°C. After fully stirring the above-mentioned completely melted alloy liquid with a graphite rod, cover the alloy liquid with high-purity flaky graphite powder with a thickness of 6 cm and keep it warm. After holding at 1000°C for 1.2 hours, take the sample out of the electric furnace, and use a direct-reading spectrometer to test the composition of the sample three to five times. If the content of each component is within the specified range, it will be placed for use. Bismuth with a...

Embodiment 2

[0029] A new lead-free environment-friendly copper-based alloy material is composed of the following components in weight percentage: 4.5% zinc, 8% tin, 2.5% bismuth, 3% silicon carbide, and the balance is copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0030] Put copper, tin and zinc in the power frequency electric furnace according to the weight percentage ratio mentioned above, heat it to 1150°C and melt it completely, then keep it warm to 1000°C. After fully stirring the above-mentioned completely melted alloy liquid with a graphite rod, cover the alloy liquid with high-purity flaky graphite powder with a thickness of 10 cm and keep it warm. After holding at 1000°C for 1.5 hours, take the sample out of the electric furnace, and use a direct-reading spectrometer to test the composition of the sample three to five times. If the content of each component is within the specified range, it will be placed for use. Bismuth w...

Embodiment 3

[0032] A new lead-free environment-friendly copper-based alloy material is composed of the following components in weight percentage: 2.5% zinc, 7% tin, 2% bismuth, 2% silicon carbide, and the balance is copper. Its manufacturing process is as figure 1 As shown, perform the following steps in sequence:

[0033] Put copper, tin and zinc in the power frequency electric furnace according to the above weight percentage distribution, heat to 1125°C and completely melt, then keep warm to 1000°C. After fully stirring the above-mentioned completely melted alloy liquid with a graphite rod, cover the alloy liquid with high-purity flaky graphite powder with a thickness of 8 cm and keep it warm. After holding at 1000°C for 1.3 hours, take the sample out of the electric furnace, and use a direct-reading spectrometer to test the composition of the sample three to five times. If the content of each component is within the specified range, it will be placed for use. Bismuth with a purity gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com