Preparation method of styrene-maleic anhydride-nitrophenyl maleimide terpolymer

A technology of maleimide terpolymer and maleimide, which is applied in the field of preparation of styrene-maleic anhydride-nitrophenylmaleimide terpolymer, can solve a large number of solvent safety problems With problems such as environmental protection, difficulty in industrial production, and excessive use of solvents, it achieves the effects of obvious heat resistance, low residual monomers, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

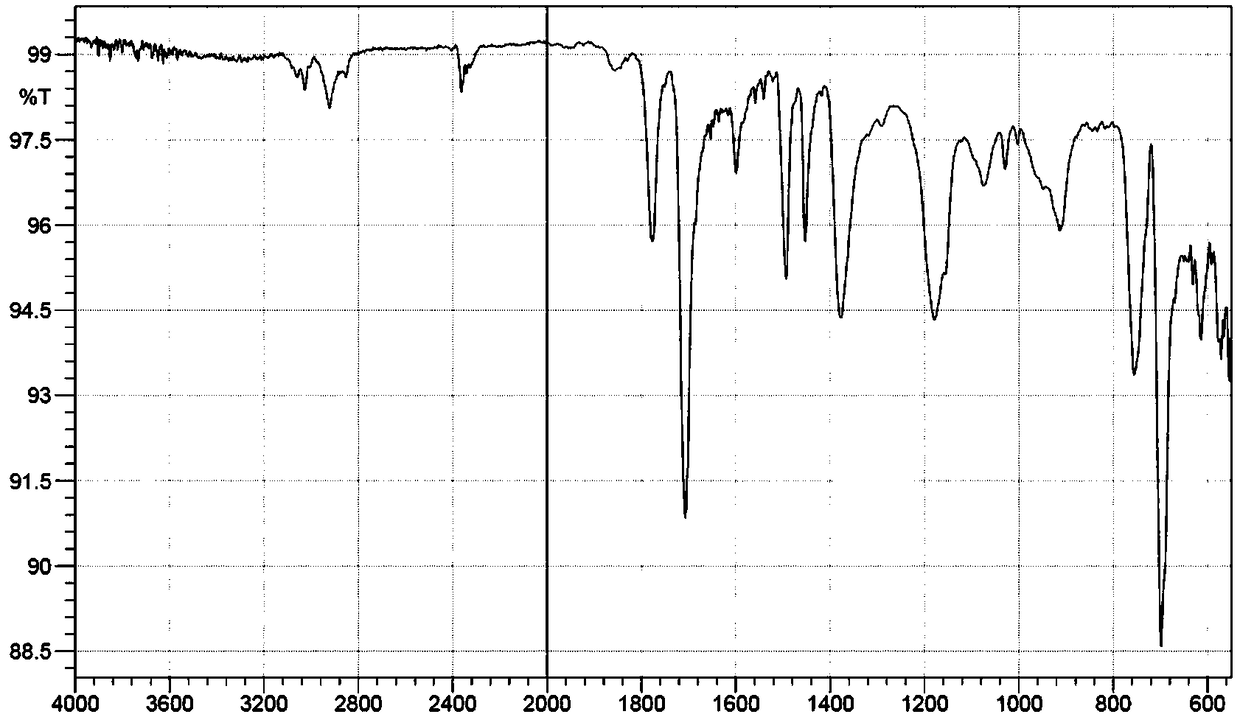

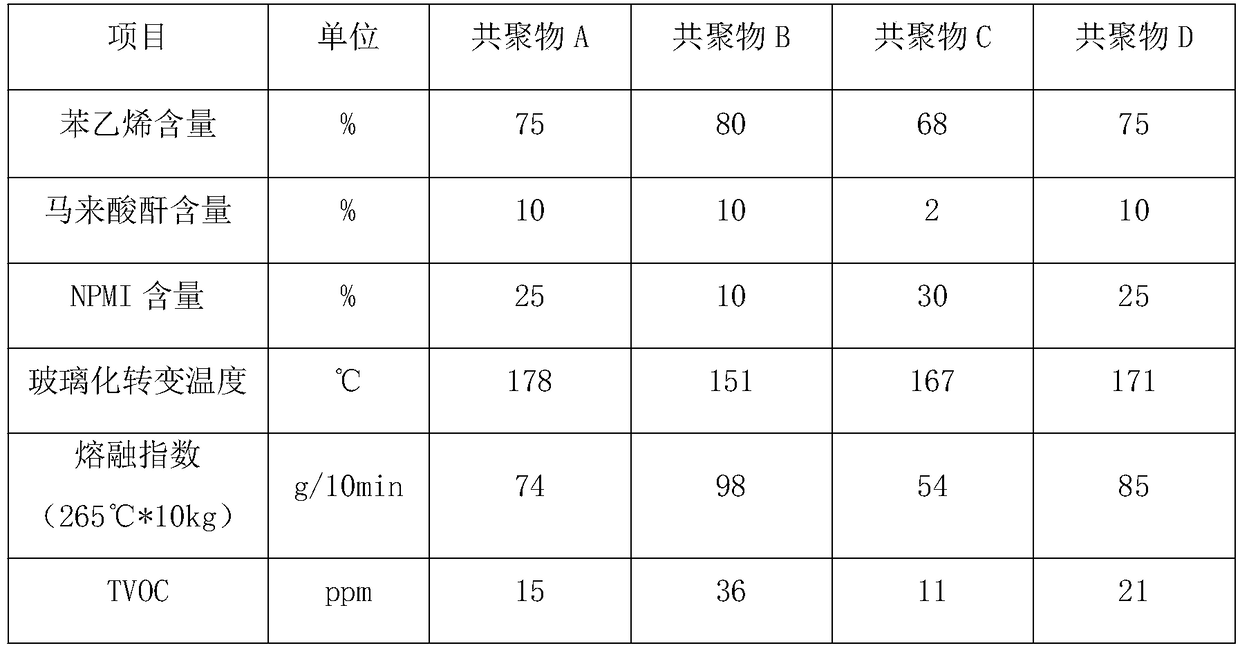

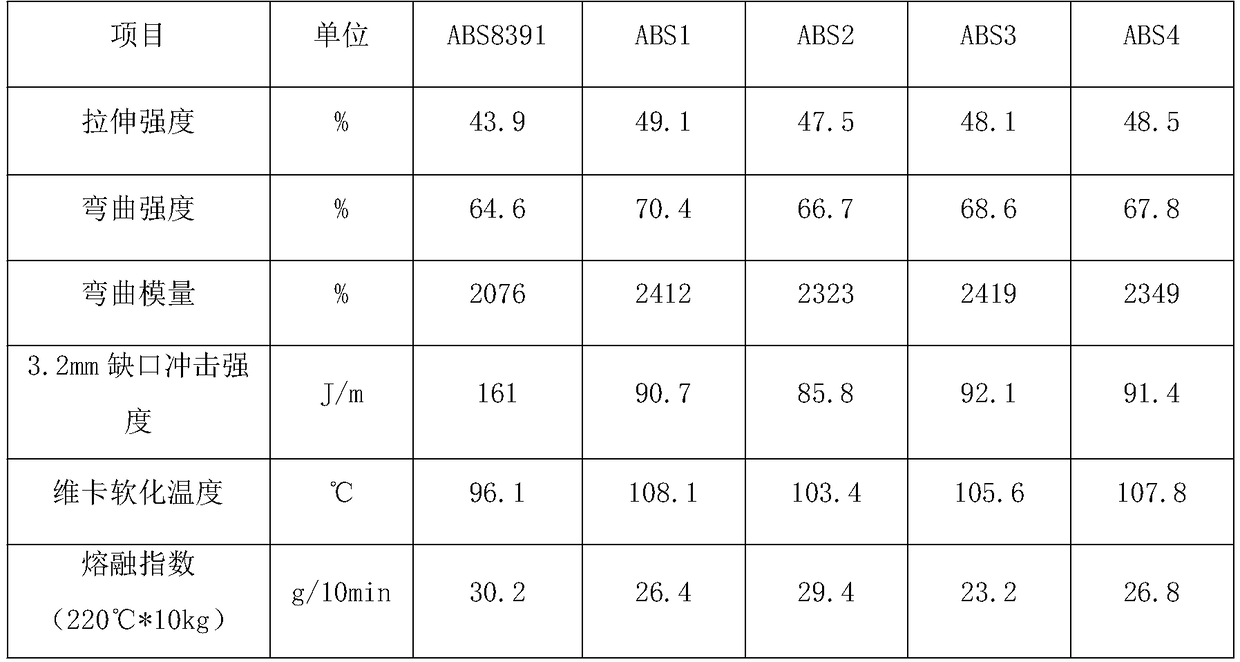

[0018] Firstly, 20 parts of styrene and 0.1 part of dodecyl mercaptan are added to the reactor, the temperature of the reactor is 115° C., and the pressure is normal pressure. Dissolve 4 parts of maleic anhydride and 10 parts of nitrogen phenyl maleimide in proportion to 64 parts of styrene and 30 parts of ethylbenzene to form a mixed solution, and then drop the mixed solution into the reaction kettle. When the conversion rate of the polymerization reaction reaches 40%, inject the resulting polymer-containing solution into a vacuum devolatilizer, and vacuum devolatilize under the conditions of 250°C and 30KPa to obtain styrene, maleic anhydride, and nitrogen benzene Base maleimide terpolymer A. Then copolymer A and ABS (Shanghai Gaoqiao 8391) were mixed and granulated in a ratio of 20:80 to obtain heat-resistant ABS1. The properties of copolymer A and ABS1 are shown in Table 1 and Table 2 respectively, and the infrared spectrogram of copolymer A is shown in figure 1 .

Embodiment 2

[0020] Firstly, 10 parts of styrene and 0.5 parts of dodecyl mercaptan are added to the reactor, the temperature of the reactor is 140° C., and the pressure is normal pressure. Dissolve 7 parts of maleic anhydride and 7 parts of nitrogen phenyl maleimide in proportion to 76 parts of styrene to form a mixed solution, and then drop the mixed solution into the reaction kettle. When the conversion rate of the polymerization reaction reaches 70%, inject the resulting polymer-containing solution into a vacuum devolatilizer, and vacuum devolatilize under the conditions of 220°C and 10KPa to obtain styrene, maleic anhydride, and nitrogen benzene Base maleimide terpolymer B. Then copolymer B and ABS (Shanghai Gaoqiao 8391) were mixed and granulated at a ratio of 20:80 to obtain heat-resistant ABS2. The properties of copolymer B and ABS2 are shown in Table 1 and Table 2, respectively.

Embodiment 3

[0022] Firstly, 10 parts of styrene are added into the reactor, the temperature of the reactor is 90°C, and the pressure is normal pressure. Dissolve 1 part of maleic anhydride and 15 parts of nitrogen phenyl maleimide in proportion to 74 parts of styrene and 10 parts of ethylbenzene to form a mixed solution, and then drop the mixed solution into the reaction kettle. When the conversion rate of the polymerization reaction reaches 50%, inject the resulting polymer-containing solution into a vacuum devolatilizer, and vacuum devolatilize under the conditions of 200°C and 4KPa to obtain styrene, maleic anhydride, and nitrogen benzene Base maleimide terpolymer C. Then copolymer C and ABS (Shanghai Gaoqiao 8391) were mixed and granulated at a ratio of 20:80 to obtain heat-resistant ABS3. The properties of copolymer C and ABS3 are shown in Table 1 and Table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com