Preparation of methyltin stabiliser

A technology of methyl tin stabilizer and dimethyl tin dichloride, which is applied in the direction of tin organic compounds, can solve the problems of continuous processing and production of unfavorable products, poor mold release, poor lubricity, and easy sticking of batch materials to rolls, etc., to achieve The effect of good product stability, high transparency, and easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

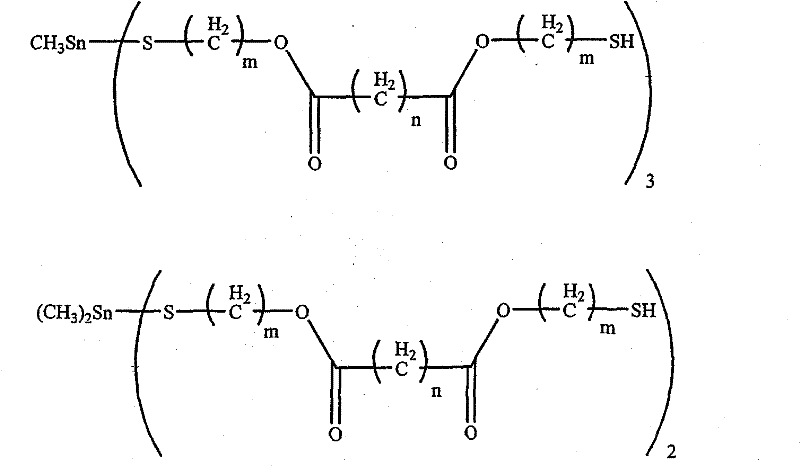

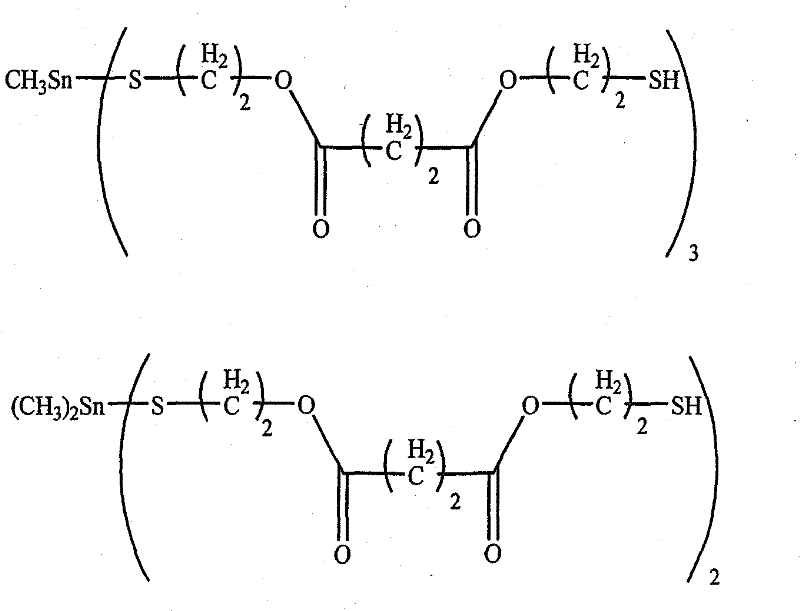

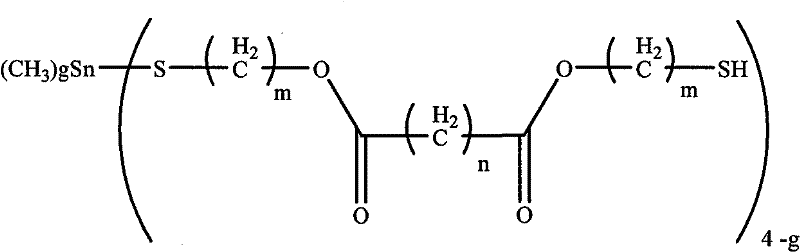

Image

Examples

Embodiment 1

[0049] After mixing 118 grams (1mol) of succinic acid (or malonic acid, or glutaric acid) with 172 grams (2.2mol) of 2-mercaptoethanol, add 200 grams of toluene, then add 0.5 grams of p-toluenesulfonic acid to reflux , after completion of the reaction, wash three times with 200ml of water, after drying, evaporate the solvent, extract low-boiling solvent and water under high vacuum, obtain 226 grams of dimercaptoethyl succinate, yield 95%.

[0050]Drop 238 grams (1mol) of dimercaptoethyl succinate into a 1:4 mixed aqueous solution of monomethyltin trichloride: dimethyltin dichloride with a chlorine equivalent of 1 mole, at a temperature of 25 to 40°C , use ammonia solution (or sodium hydroxide solution or sodium bicarbonate solution) to adjust the pH value of the system to 7-8. After esterification, the temperature was 40-60°C for 4 hours. After the reaction, the water phase was separated, and the organic phase was washed 3 times with 300 grams of water. The water phase was sep...

Embodiment 2

[0054] After mixing 146 grams (1mol) of adipic acid with 148 grams (1.9mol) of 2-mercaptoethanol (or 3-mercaptopropanol, 2-methyl-2-mercaptoethanol, or 4-mercaptobutanol), add 200 grams Toluene (or sherwood oil or n-hexane or hexanaphthene or chloroform or benzene), then add 2 grams of benzenesulfonic acid or methanesulfonic acid) backflow, after completion of the reaction, wash three times with 200ml water, after drying, evaporate the solvent, The low-boiling point solvent and water were extracted under high vacuum to obtain 250 g of dimercaptoethyl adipate, with a yield of 94%.

[0055] Add 266 grams (1 mol) of dimercaptoethyl adipate dropwise into a 1:6 mixed aqueous solution of monomethyl tin trichloride: dimethyl tin dichloride with a chlorine equivalent of 1 mole at a temperature of 0 to 30°C , use ammonia solution (or sodium hydroxide solution or sodium bicarbonate solution) to adjust the pH value of the system to 7-8. After esterification, the temperature was 60-90°C ...

Embodiment 3

[0059] After mixing 146 grams (1mol) of adipic acid with 312 grams (4mol) of 2-mercaptoethanol (or 2-methyl-2-mercaptoethanol, or 4-mercaptobutanol), add 400 grams of n-hexane or cyclohexane or Chloroform or benzene), then add 5 grams of benzenesulfonic acid or methylsulfonic acid) to reflux, after the reaction is complete, wash three times with 200ml of water, after drying, evaporate the solvent, and extract the low-boiling solvent and water under high vacuum to obtain 250 grams of hexane Dimercaptoethyl diacid, yield 94%.

[0060] Add 266 grams (1 mol) of dimercaptoethyl adipate dropwise into a 1:2 mixed aqueous solution of monomethyl tin trichloride: dimethyl tin dichloride with a chlorine equivalent of 1 mole, at a temperature of 0 to 30°C , use ammonia solution (or sodium hydroxide solution or sodium bicarbonate solution) to adjust the pH value of the system to 7-8. After esterification, the temperature was 60-90 °C for 6 hours. After the reaction, the water phase was se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com